amixon® manufacturing programme

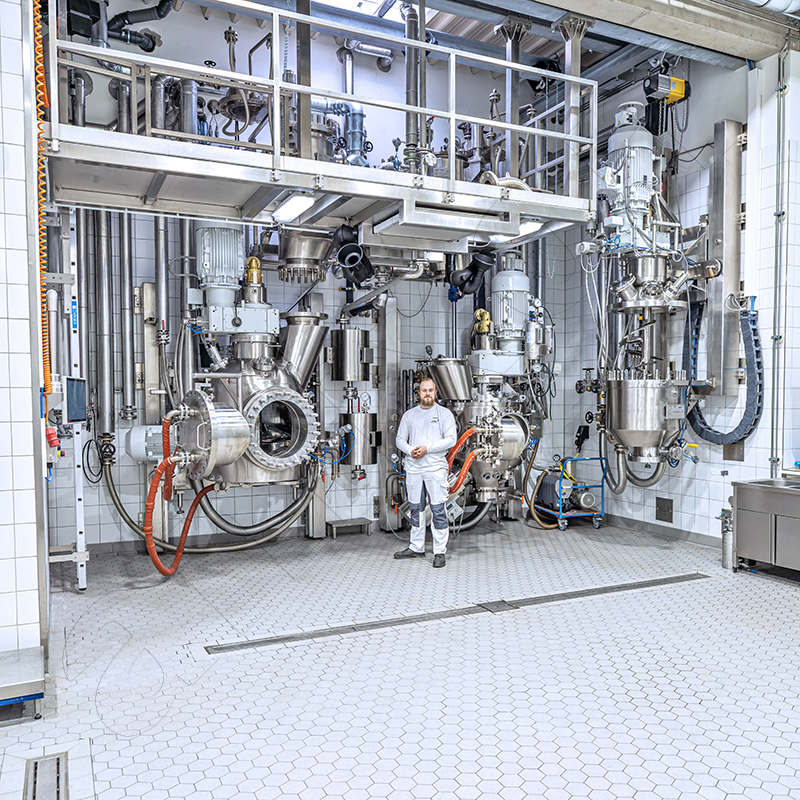

Ideal mixing qualities with optimum hygiene. This is only possible with precision in manufacturing. The amixon® production meets the highest standards.

amixon® has a unique range of precision mixers blenders. These blenders are used in all industries where high-quality powders are mixed, refined or chemically modified. The powders can be dry, moist or suspended. For 40 years, our team has been exclusively involved in blending, mixing, vacuum mix drying, synthesis reactions, agglomeration and build-up granulation.

amixon® appliances belong to the premium sector. They meet the highest demands such as:

- Achieving ideal mixing qualities, even with heterogeneous goods, if their components have different particle sizes and bulk densities

- Highest hygiene requirements; adapted to a wide range of cleaning regimes

- Maximum flexibility

- Best residue emptying

Each mixing / blending operation has its own specific requirements when a mixer / blender is to be purchased. All the many requirement points are difficult to specify. In the amixon GmbH technical centre, we help our customers to select and define the machine features. Every amixon® mixer is unique; always specially adapted to the respective requirement situation.

Let us advise you comprehensively and try out the amixon® mixers / blenders in our factory pilot plant or in your production environment. More than 30 amixon® test mixers are at your disposal!

How does amixon® offer flexibility in the selection and configuration of its mixers to meet the individual requirements of my business?

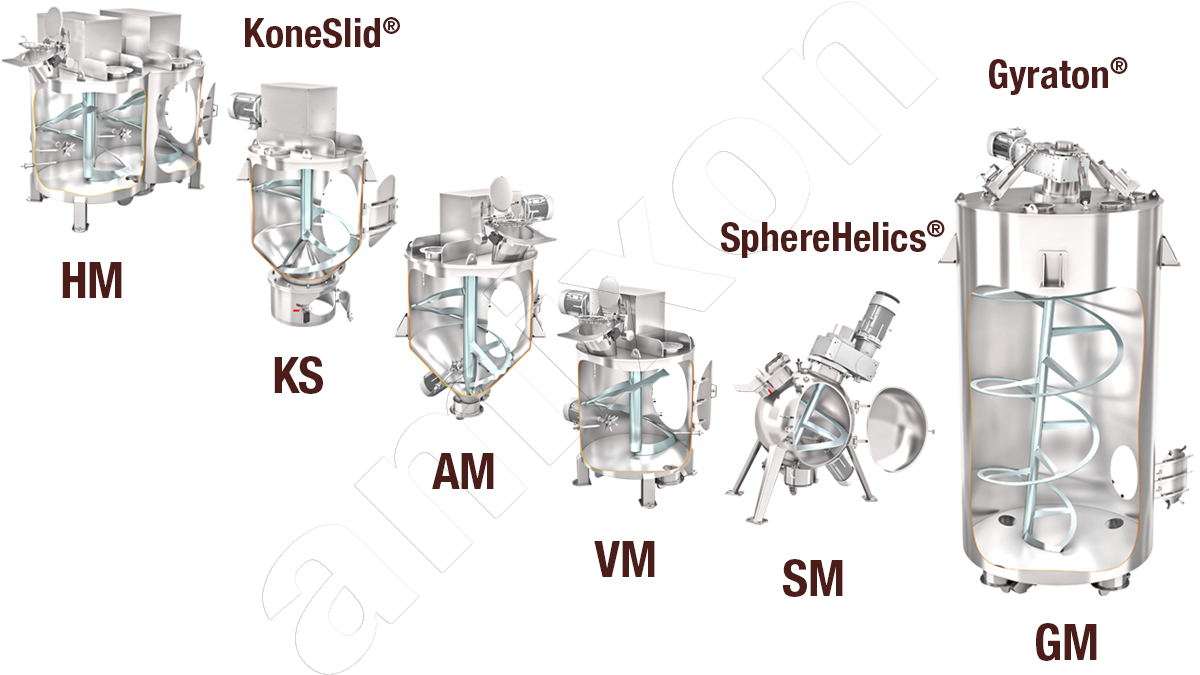

amixon® offers a uniquely wide range of vertical precision mixers. Each of the models shown here has specific features that are specially tailored to the needs of professional mixing operations. Our expertise is backed up by the fact that amixon® has more than 30 different test mixers available.

amixon® also has test centres in China, India, Japan, Korea, the Benelux countries and the USA.

The ranking shown roughly symbolises the diversity of the application ranges. amixon® mixers offer users many advantages:

- The mixing tools are only driven and mounted at the top.

- They mix quickly – regardless of the filling level.

- They empty almost completely.

- They are particularly easy to clean and inspect.

- amixon® mixers have large inspection doors and meet the highest hygiene standards.

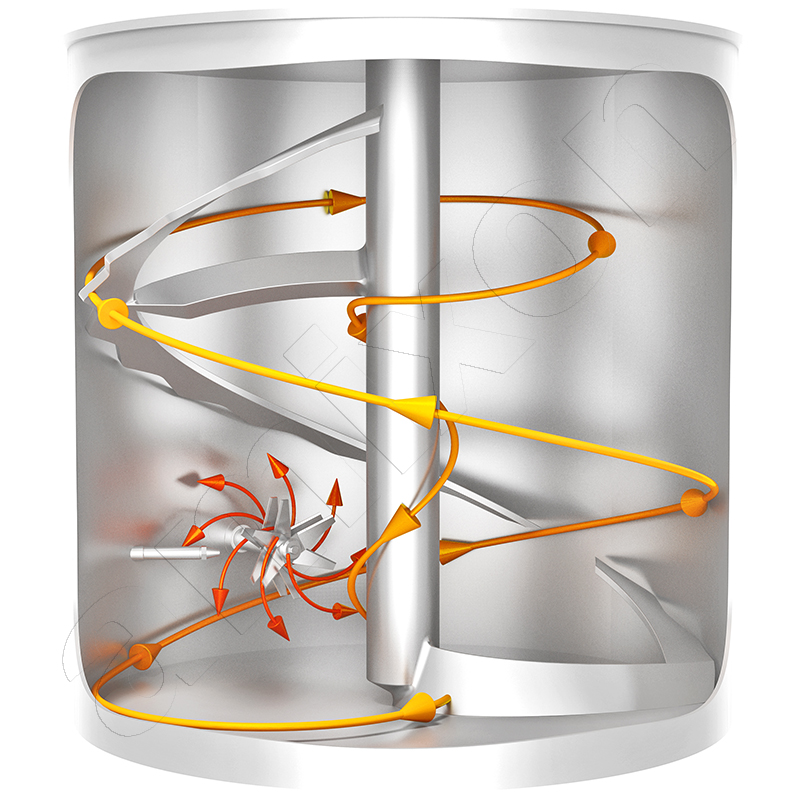

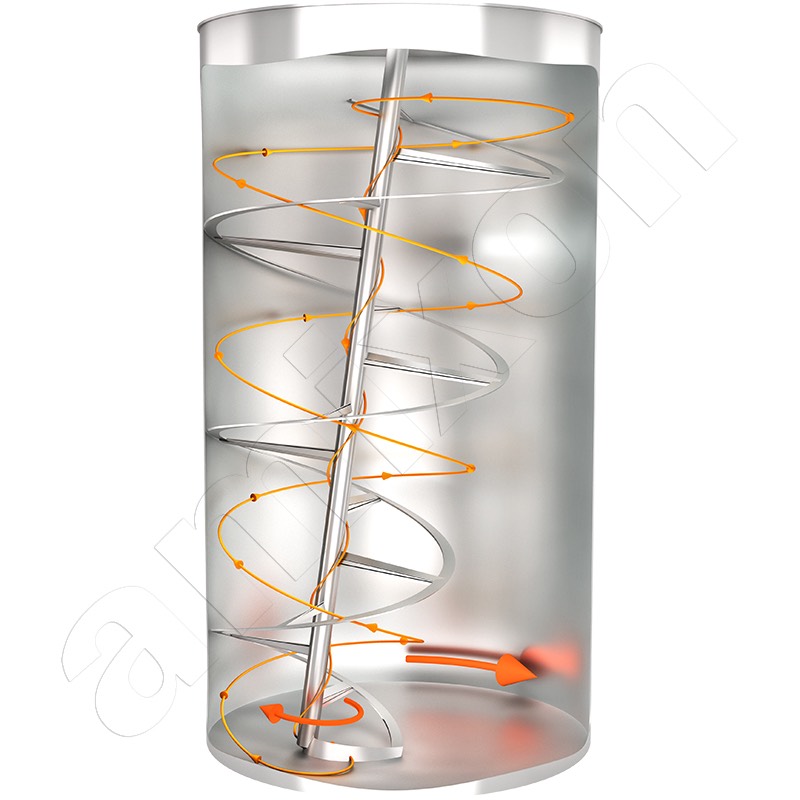

The Gyraton® mixer shown on the right is a silo mixer. It is used for large and very large batches of mixed material from 10 m³. It mixes with extremely low drive power and still achieves optimum mixing quality.

How does amixon® ensure that its mixers meet the highest hygiene requirements and can be adapted to different cleaning regimes?

Thousands of amixon® mixers are successfully in use worldwide. A wide variety of industries benefit from our in-depth understanding of their specific hygiene requirements.

We take into account the different degrees of contamination as well as hygiene standards dictated by ethics and culture, such as halal, kosher or the processing of allergenic or non-allergenic substances. Industry-specific tolerance ranges are also incorporated into the cleaning regimes of our mixing systems.

It is extremely important that amixon® mixers empty themselves completely, up to 99.97%, when the mixed materials are free-flowing.

Pharmacy, dietetics, food supplements, bakery products, life science, baby food, vegan nutrients, instant products, instant drinks, enzymes, herbs, tea, muesli, spices, cereals, animal feed, starch, cellulose derivatives, fine chemicals, plastics industry, vacuum or inert gas, active ingredient syntheses, vacuum contact drying, formulation, metal soaps, washing-active substances, ceramic high-performance materials, 3D printing, adaptive manufacturing, powder metallurgy, complete emptying, .....

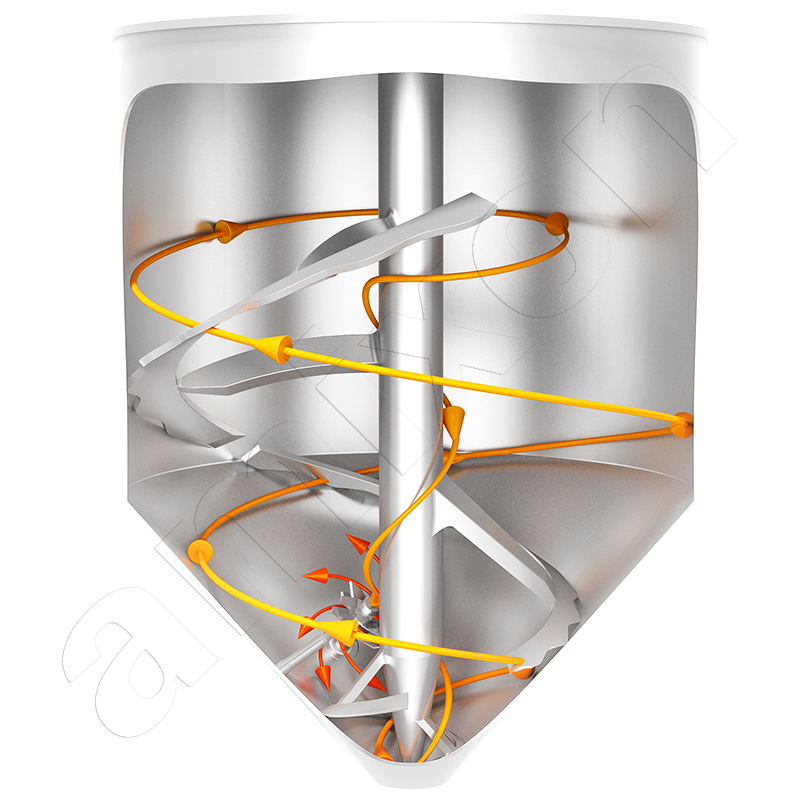

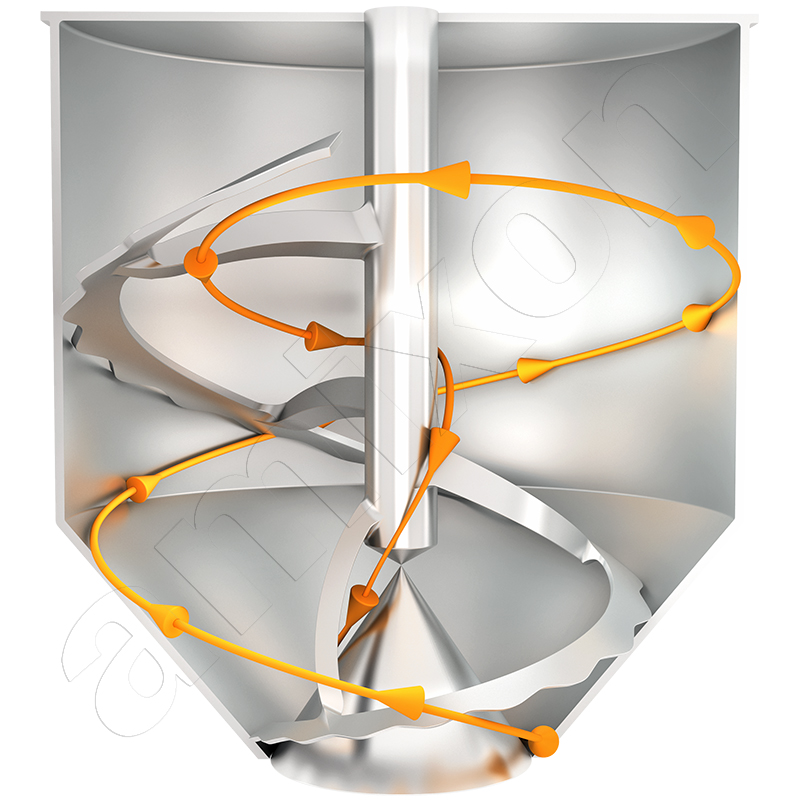

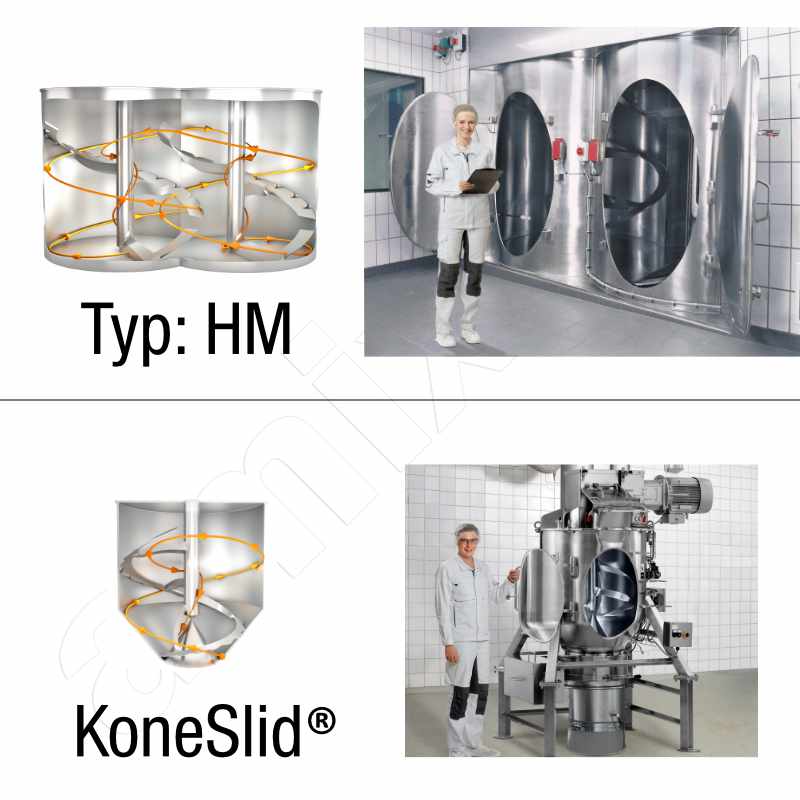

Vertical mixer / blender for highest precision when mixing bulk materials

The HM, KS, AM, SH (SpherHelics®)and VM mixing / blending systems are precision mixers with very short mixing times. They are mostly produced with batch volumes of 600 litres to 10 000 litres. These mixers / blenders can be used for almost all types of dry, wet and suspended solids. As a twin-shaft mixer / blender, the HM type offers maximum efficiency. The mixing time of the HM is extremely short; depending on the task, approx. 0.25 to 5 minutes. The AM and VM mixing / blending systems are single-shaft mixers. Their mixing times are approx. 3 to 7 minutes, depending on the task. The achievable mixing qualities of all amixon® mixers / blenders always correspond to an ideal homogeneity that can no longer be improved in practice.

Can the properties of the HM and KS mixing systems be compared?

The characteristics are quite similar in terms of the gentle, gentle way of blending. Both systems ensure maximum efficiency. The powder particles are mixed in such a way that their shape is not changed. The HM type is often used when large batches need to be mixed / blended gently.

The KoneSlid® is manufactured for batch sizes up to 3 m³. It is used when the mixing time is extremely short and when the complete discharge is to take place in a few seconds. It realises cycle times of 1 to 4 minutes. The cycle time in this context is the sum of the times for filling, mixing, discharging and closing the discharge fitting. However, the same mixer / blender can also discharge in doses or portions.

For which preparation tasks was the Gyraton® mixer developed?

The amixon® large blender / mixer type GM is a new development. It is used when a large batch of similar goods is to be homogenised. In this respect, the Gyraton® mixer / blender differs from the other amixon® blenders. It is not used when you want to distribute a micro-component in a batch of mixed material. That would take a relatively long time.

Bulk goods such as tea, herbs, spices, food stabilizers, tobacco or chemical raw materials are often delivered from overseas in 40-foot ocean-going containers. It must be assumed that the goods in the container have different qualities, particle sizes, bulk densities, degrees of moisture, colour and taste properties, etc. A uniform quality determination can only take place if statistically validated samples are taken and analysed.

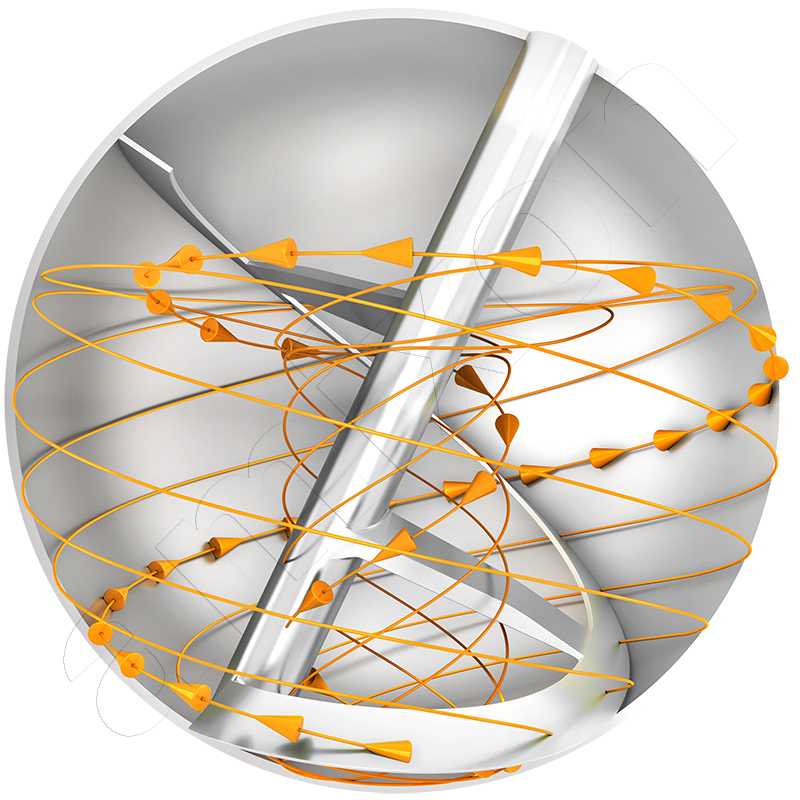

Sampling only makes sense if the total mass has been blended beforehand. The Gyraton® mixer can gently homogenize / blend large quantities. Its engine power is low. The mixing unit rotates slowly. The mixing tool grazes the bottom and the entire cylinder wall at a defined distance. It records all volume parts of the mixing chamber without dead space. The mixing time can be preset depending on the motor power and rotation frequency. The Gyraton® mixer / blender from amixon® is particularly compact and meets the highest hygiene requirements. Compared to a conical screw mixer with the same effective volume and the same diameter, the overall height of the Gyraton® is only one third.

As a potential buyer, what options do I have for testing the mixing quality and suitability of an amixon® mixer in advance?

amixon® offers a uniquely wide range of vertical precision mixers; more than 30 different test mixers are available in Paderborn. amixon® also has test centres in China, India, Japan, Korea, the Benelux countries and the USA. Why not visit us with your problematic products? We are confident that we can find the best possible solution for your processing task.

High-performance cameras can be used to measure particle sizes and shapes practically online and evaluate them statistically using other analysis methods. But none of this can replace practical mixing trials. Not even the most sophisticated simulation programme. Bulk solids are far too complex for that. There is no substitute for practical mixing trials/processing trials.

© Copyright by amixon GmbH