Products of powder metallurgy

In powder metallurgy, metallic components are created from precisely defined metal powders. These powders are intentionally processed, mixed, and then further processed through compaction and sintering. The process allows for very precise adjustment of material properties and component geometries - reliably and reproducibly.

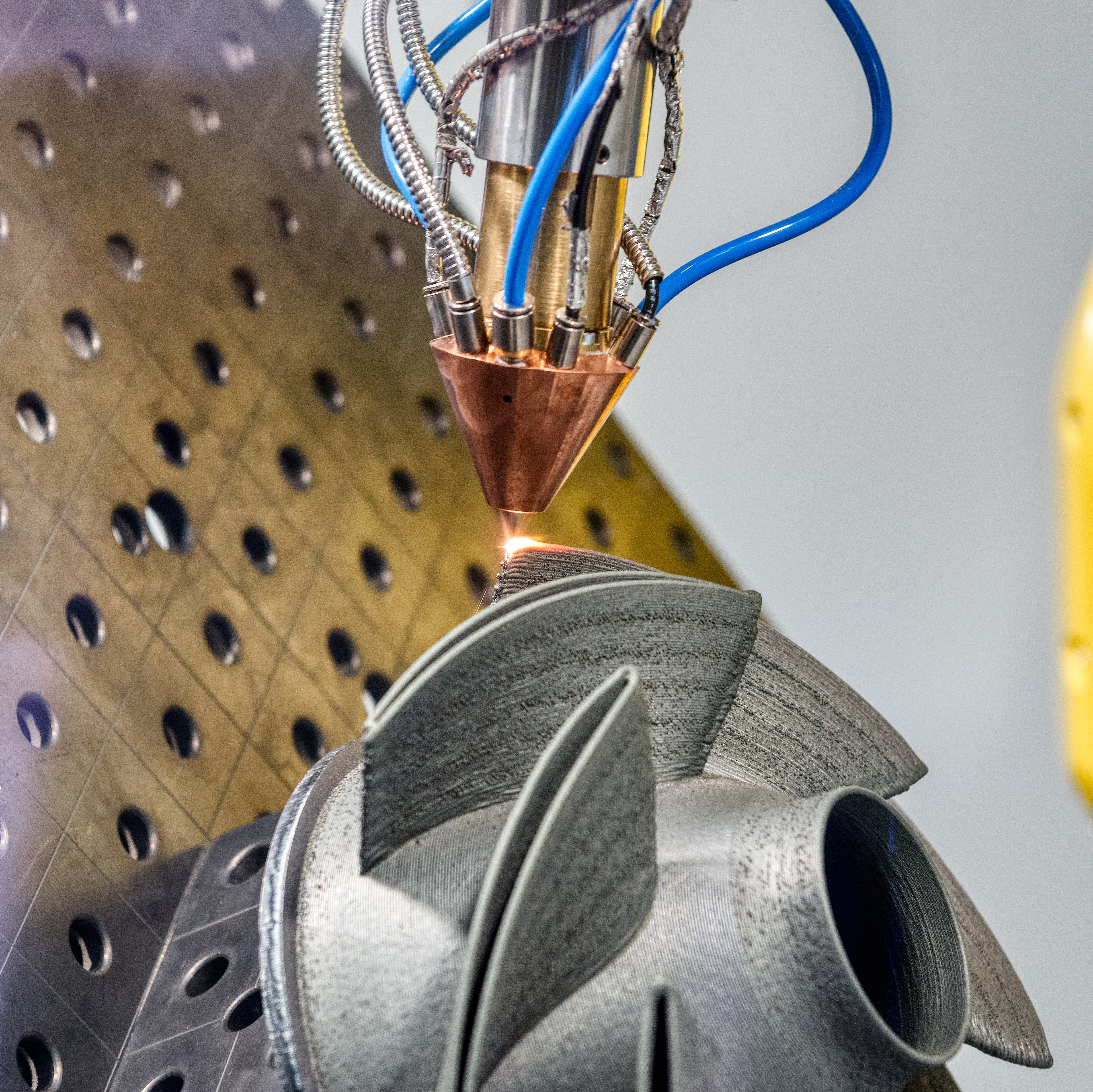

Powder metallurgical products are indispensable in many industries. They are used in traditional applications such as bearings, gears, or filters as well as in additive manufacturing of metallic components. In all these areas, the quality of powder processing determines how stable processes run and how consistent the component quality is in the end.

Typical products and technical terms in powder metallurgy:

- Metal powders based on iron, stainless steel, titanium, or nickel

- Alloy and additive mixtures

- Powder blends for pressing and sintering processes

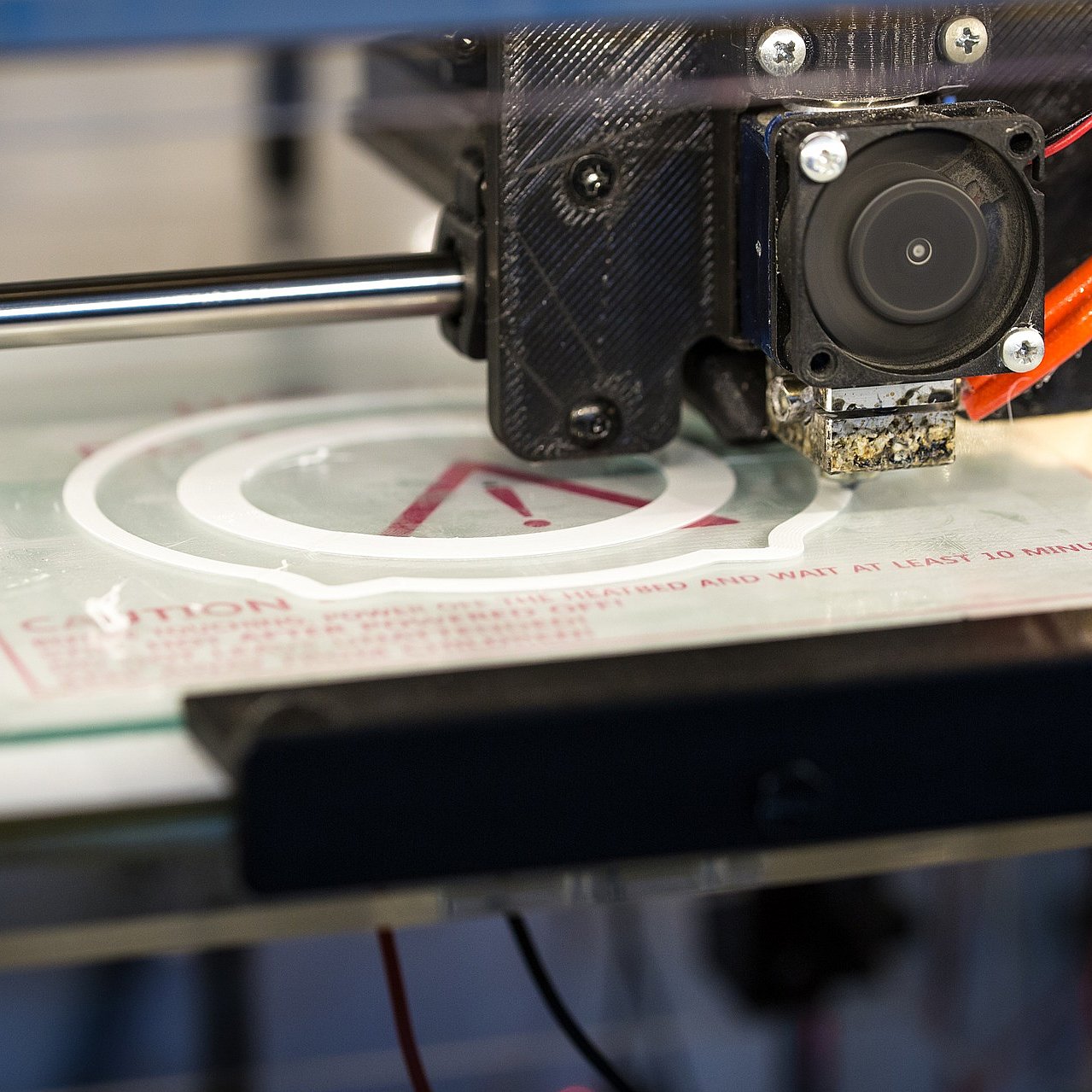

- Metal powders for additive manufacturing processes (Metal AM)

- Functionalized powders with flow or compaction aids

Requirements for mixing, drying, and processing

Powder metallurgical processes place high demands on powder preparation. Additives, alloying elements, or flow aids must be evenly distributed - because even small deviations affect compaction and sintering behavior. At the same time, the powders must not "suffer". Abrasion, grain destruction, or demixing change flowability and bulk density and make processes unstable. This is particularly critical in additive manufacturing, where uniform powder layers and reproducible dosing are crucial. In many applications, wetting or coating steps with subsequent drying are also added, requiring controlled heat transfer.

amixon® solutions for powder metallurgy

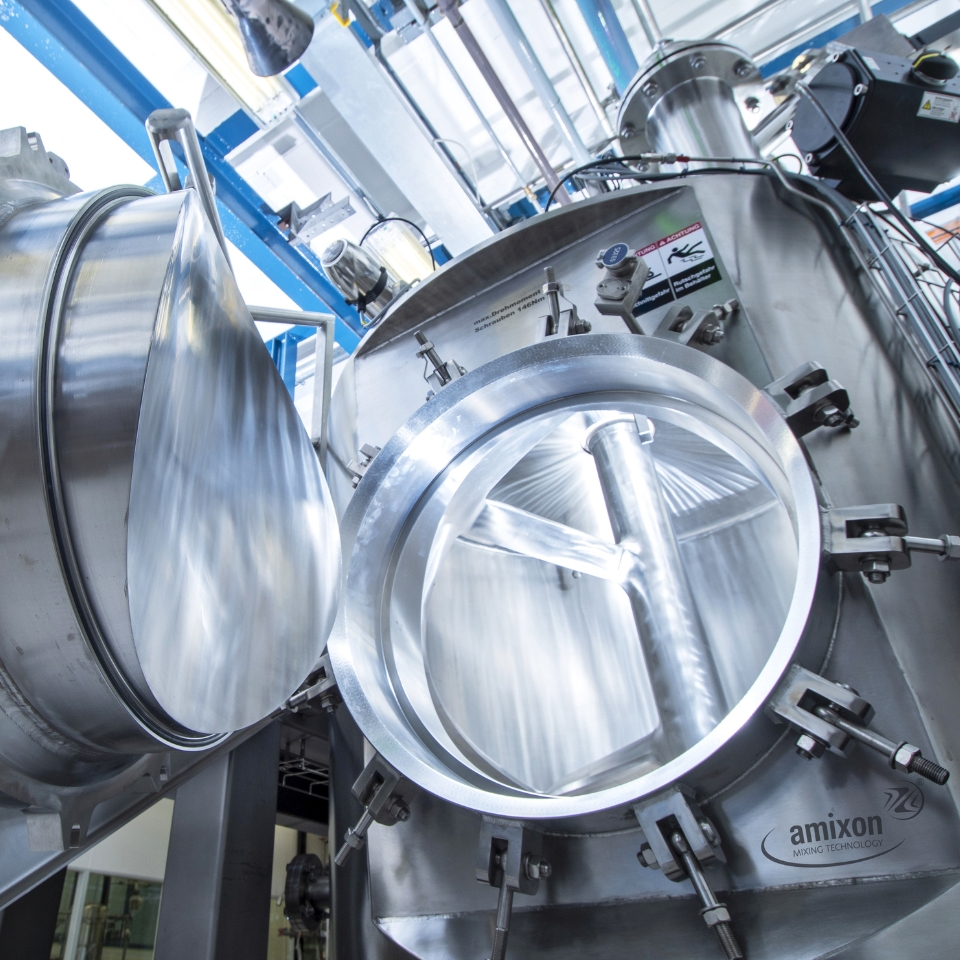

amixon® develops and builds mixing, mixing-drying, and reactor technology for industrial powder processes that require homogeneity, reproducible powder characteristics, safe process control, and gentle handling of the product.

A special focus is on applications with abrasive metal powders. Here, wear-resistant designs of mixing tools and product-contact surfaces ensure that abrasion is reduced and the systems operate reliably even with challenging powders.

Typical process engineering tasks:

- uniform distribution of additives and alloy components

- product-friendly powder preparation for pressing and AM processes

- wetting and subsequent controlled drying

- safe emptying and easy cleaning during product changes

amixon® process machines at a glance

The AMT is designed for processes with high demands on heat transfer and process control. Heatable walls, mixing tools, and floor surfaces enable uniform, efficient drying of even demanding intermediate products. The conical bottom supports clean residual emptying and facilitates product changes.

The VMT combines mixing, drying, and reacting in a closed apparatus. The use of vacuum allows moisture or wetting agents to be gently removed, while the uniform product movement ensures homogeneous heat and mass transfer.

The HM mixer allows for short mixing times with high homogeneity. It is suitable for intermediate and final mixtures with different bulk densities and particle sizes when reproducible results are required.

The Gyraton® mixer is a precision silo mixer for large batches of 10 to 100 m³. The slow, controlled product movement ensures high mixing quality with low energy consumption, high residual discharge rates, and a compact design.

Technical college and process development

In the amixon® technical center, powder metallurgical processes can be investigated in a practical manner. Mixing quality, flow behavior, drying, emptying, and cleanability are considered together and specifically designed for industrial use.

Powder metallurgy thrives on precision - even small details in powder processing make the difference. Those who want to ensure homogeneity, product protection, and reproducible results need process technology that is precisely designed for this purpose. amixon® develops and builds this technology. Speak to us about your powder metallurgy processes, your materials, and your production goals. amixon® - Process technology for metal powders and demanding applications.

Contact us!

Contact us!