Toast flours; deactivate enzymes

Flour, milled grains toasting and enzymatic deactivation, sterilization. Batch flour treatment versus continuous flour treatment

In principle, enzymes are indispensable for the production of high-quality baked goods. Flours such as amaranth flour, buckwheat flour, barley flour, oat flour, millet flour, corn flour, quinoa flour, rye flour and wheat flour can be made low-germ by thermal action. The enzymes in the flour are then largely deactivated.

Thermally treated flours, grains act as binders or also as food stabilizers for instant foods, convenience foods or also in dietetic foods. In commercial kitchens, toasted flours are valued as a lump-free and tasteless binder. Thermally treated flours can be easily wetted. They can also serve as a carrier for tablets, spices and flavorings.

Instant flours generally wet well with water, with oil and also with emulsions. They can be used, for example, as a bonding agent or wet panade for vegetables, fish and meat. The properties of the dispersion, such as viscosity and adhesion, are predetermined by heat treatment. In rare cases, the grain is thermally treated, steamed, boiled or roasted prior to comminution.

If the vocabulary "steam sterilization" is used in this context, the following restriction applies: What is meant is by no means sterilization in the medical sense. As a rule, agricultural products are not sterile. In the present case, it is only a reduction of unwanted germs and enzymes.

Flour treatment batchwise

Carrying out germ and enzyme reduction in batches offers a great deal of flexibility. amixon® sterile reactors of the AMT or VMT design are particularly well suited for this purpose. Batch processing makes it possible to adapt the germ and enzyme reduction precisely to the powder characteristics. The process temperatures and the associated residence times can be balanced against each other. Variable rotational frequencies of the mixing tools are used to control the mechanical energy input. In addition, vacuum drying and cooling of the goods can take place.

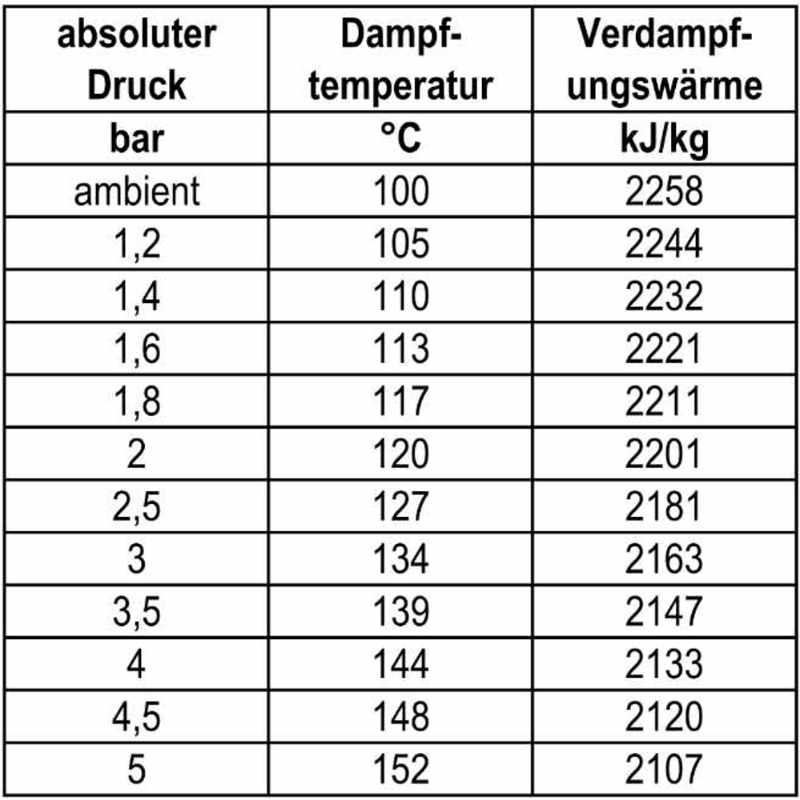

Water vapor is introduced into the moving mix. The mixing chamber is pressure-resistant and completely temperature-controlled. The flour is heated and mixed. Optionally, the mixing chamber can be vacuumed in advance. As steam is introduced, the pressure in the mixing chamber increases in accordance with the steam quantity and temperature. The sterile reactor allows much higher temperatures than 100°C.

The thermal energy of the steam is released on the surface of the grain/flour particles. At the moment of condensation, the thermal energy is transferred very effectively into the flour particles. The flour is heated, enzymes and germs are effectively deactivated.

The amixon® sterile mixer VMT shown above favors this in a special way:

1. the heating of all machine parts in contact with the product ensures that the water vapor condenses only on the mixer particle.

2. the gentle, careful way of mixing guarantees that the particle structure of your flour is preserved in the best possible way.

Filling, storage life and conditioning

After completion of the thermal treatment, two or sometimes even three important process steps must take place:

- The excess moisture must be removed from the flour.

- The flour must be cooled down to room temperature before it can be filled/packaged.

- Optionally, powdered or liquid components can be added before the filling process begins Points 1 and 2 happen quickly, effectively and simultaneously in the same amixon® sterile mixer by drying and cooling the mix under vacuum application. With the measure for point 3, the functionality of the flour can be adjusted.

After completion of the thermal treatment, two or sometimes even three important process steps must take place:

- The excess moisture must be removed from the flour.

- The flour must be cooled down to room temperature before it can be filled/packaged.

- Optionally, powdered or liquid components can be added before the filling process begins Points 1 and 2 happen quickly, effectively and simultaneously in the same amixon® sterile mixer by drying and cooling the mix under vacuum application. With the measure for point 3, the functionality of the flour can be adjusted.

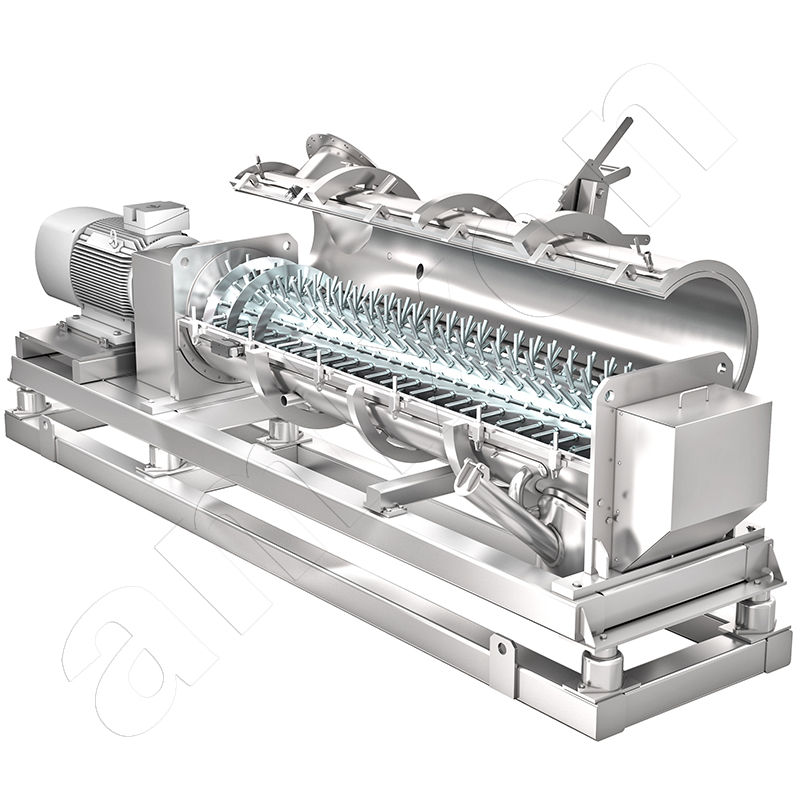

Continuous flour treatment

Heated ring-layer mixers/granulators (type: RMG) operate continuously. The residence time of the mixed materials is short. Also, the contact of flour and steam is only for a short time. The heating of the flour results from the condensation of the steam on the flour particles. The mixing chamber of the ring paddle mixer should also be heated. Depending on the frequency of rotation and the type of mixing tools, the flour can also leave the RMG agglomerated.

Continuous wetting processes can only take place at ambient pressure. Mixing and steam treatment cannot take place at positive pressure or vacuum application. After thermal treatment, the flour may have to be dried and cooled. Continuously operating fluidized bed dryers/coolers are used here, among other things.

Heated ring-layer mixers/granulators (type: RMG) operate continuously. The residence time of the mixed materials is short. Also, the contact of flour and steam is only for a short time. The heating of the flour results from the condensation of the steam on the flour particles. The mixing chamber of the ring paddle mixer should also be heated. Depending on the frequency of rotation and the type of mixing tools, the flour can also leave the RMG agglomerated.

Continuous wetting processes can only take place at ambient pressure. Mixing and steam treatment cannot take place at positive pressure or vacuum application. After thermal treatment, the flour may have to be dried and cooled. Continuously operating fluidized bed dryers/coolers are used here, among other things.

Question from a customer: What testing option can amixon offer?

Response from amixon®: We welcome you to the purpose of testing. The amixon® pilot plants are excellently equipped. Suitable test apparatus is available in the amixon GmbH technical center. Testing of the process described above should take place with your original product. Preliminary tests can take place on a 10 liter scale. For the main trials the batch size should be about 200 liters. In this way, together we can very accurately identify and specify specific process requirements.

Afterwards, you will receive your modified product back and a test protocol prepared by us. One or two trial days at amixon® will provide you with a great deal of information. During your visit you will learn useful details about cleaning and hygienic process equipment. A factory tour will provide you with valuable insights into hygienic apparatus engineering.

Response from amixon®: We welcome you to the purpose of testing. The amixon® pilot plants are excellently equipped. Suitable test apparatus is available in the amixon GmbH technical center. Testing of the process described above should take place with your original product. Preliminary tests can take place on a 10 liter scale. For the main trials the batch size should be about 200 liters. In this way, together we can very accurately identify and specify specific process requirements.

Afterwards, you will receive your modified product back and a test protocol prepared by us. One or two trial days at amixon® will provide you with a great deal of information. During your visit you will learn useful details about cleaning and hygienic process equipment. A factory tour will provide you with valuable insights into hygienic apparatus engineering.

Trial performance with an amixon® sterile reactor

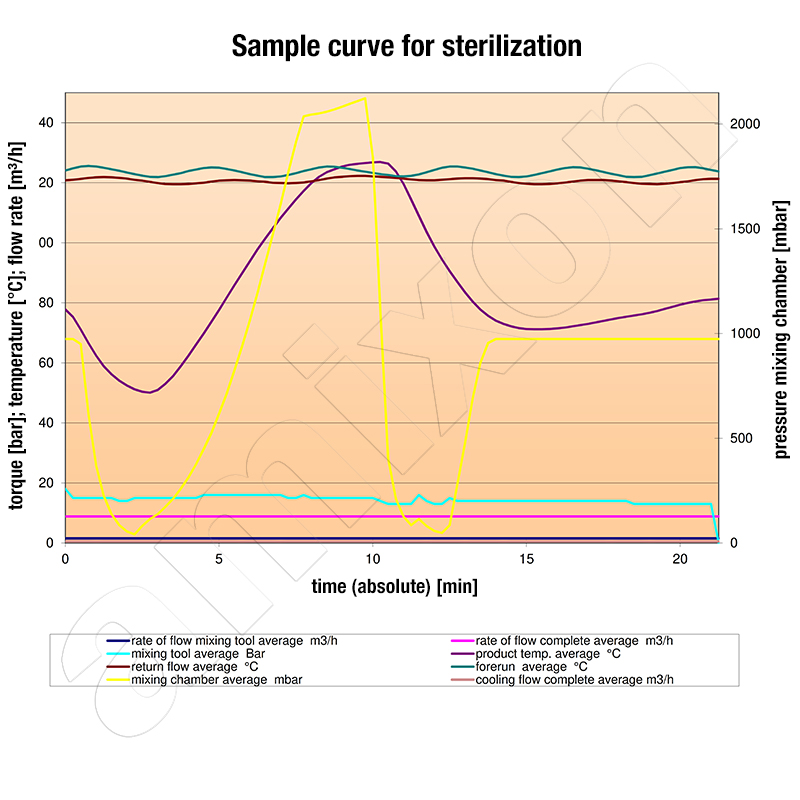

Protocol of a test run. The violet-blue line shows the course of the mix temperature, the yellow line shows the course of the pressure in the mixing chamber. The period shown is approximately 22 minutes. All parts of the mixer that come into contact with the product are temperature-controlled, including the mixing tools. The mixing process accelerates the heating of the material to be mixed. The heating of the powder takes place particularly quickly when sterile steam is introduced into the mixing chamber. The higher the system pressure in the mixing chamber, the higher the achievable temperature.

Protocol of a test run. The violet-blue line shows the course of the mix temperature, the yellow line shows the course of the pressure in the mixing chamber. The period shown is approximately 22 minutes. All parts of the mixer that come into contact with the product are temperature-controlled, including the mixing tools. The mixing process accelerates the heating of the material to be mixed. The heating of the powder takes place particularly quickly when sterile steam is introduced into the mixing chamber. The higher the system pressure in the mixing chamber, the higher the achievable temperature.

© Copyright by amixon GmbH