Prepare baking agents in amixon® precision mixers

Baking improvers are highly complex powdered mixed concentrates consisting of more than 10, sometimes even more than 50 different components, which also include liquid additives such as fats, oils, water, molasses, lecithins, syrups, honey, baking extracts, etc.

A welcome side effect is that the more liquid admixtures are mixed in, the lower the dust content of the baking agents. However, if the proportion of liquid is too high, or if the baking agent heats up during mixing, its flowability and dosing properties will deteriorate. The baking agent might even clump after packaging.

A precision mixer for baking agents must work particularly efficiently.

The ideal mixing quality of the baking powder must be achieved quickly and with minimum energy input. The way the liquid is mixed in also affects the final product.

- How flowable is the baking agent?

- Can it be stored for a long time?

- Does it tend to clump, stick or solidify?

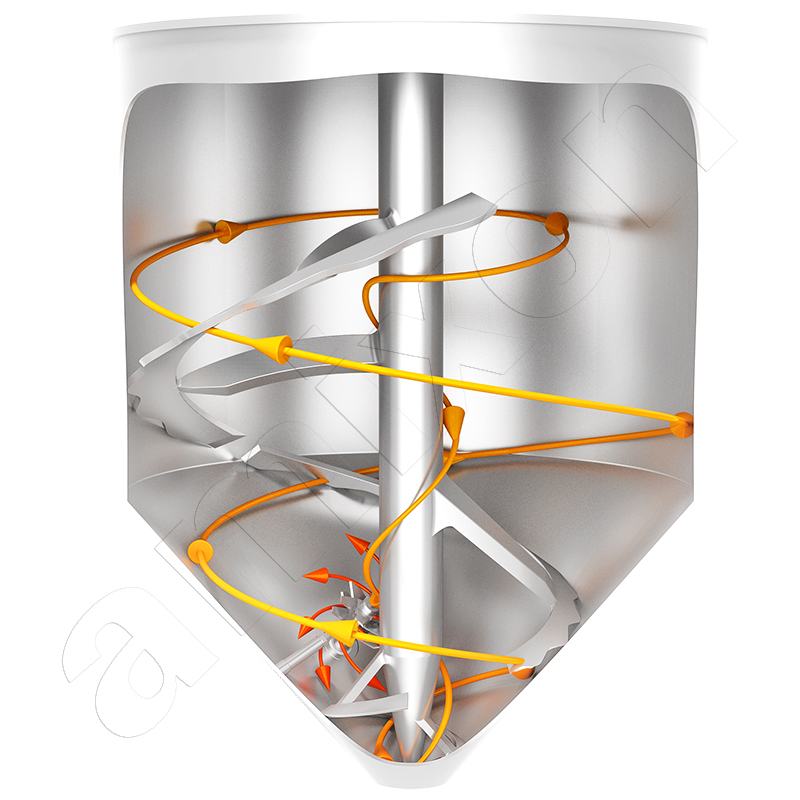

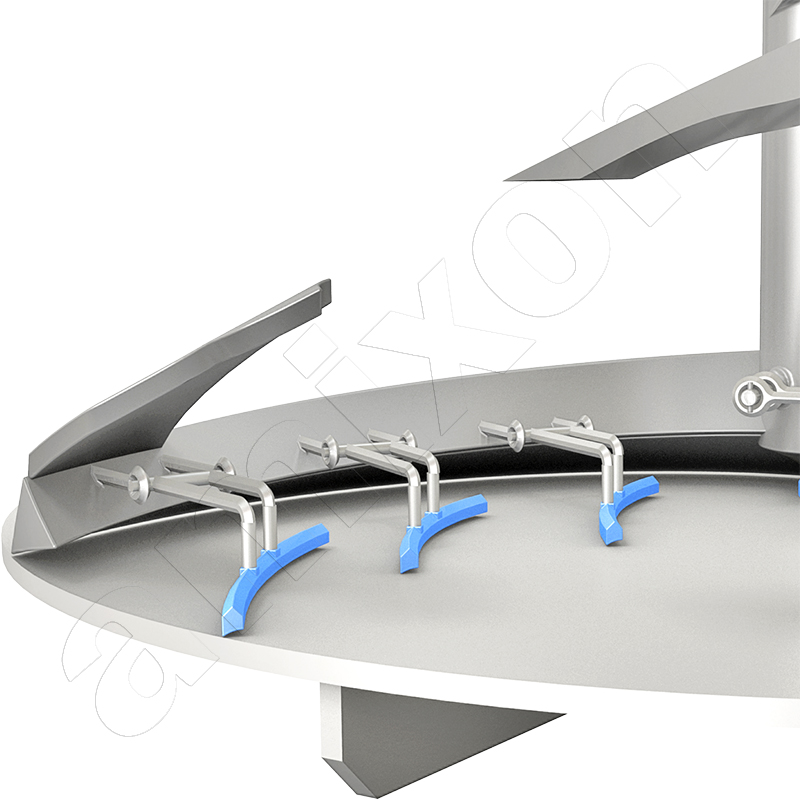

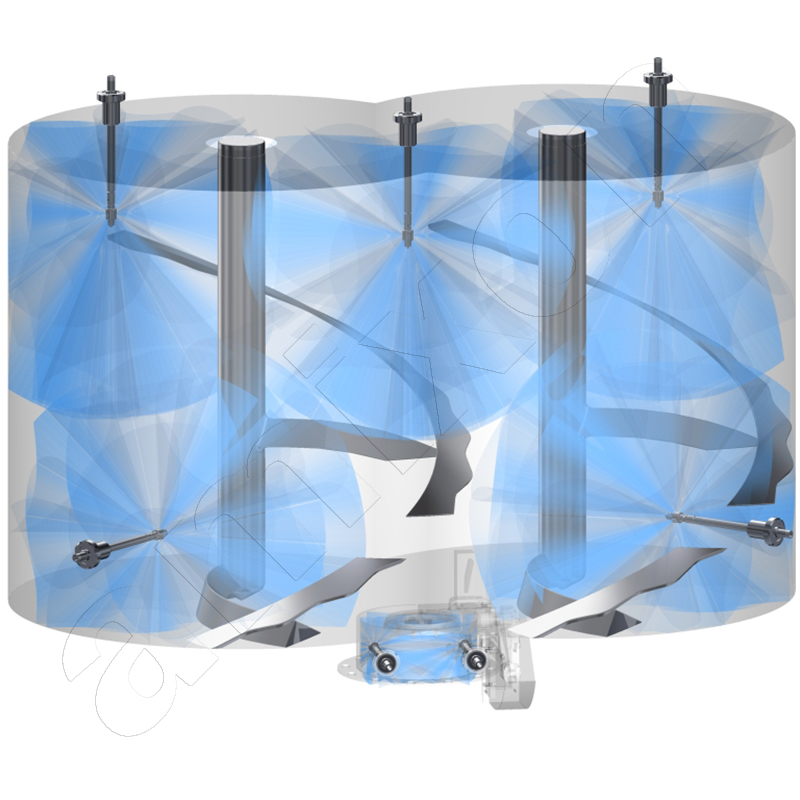

Gentle mixing and wetting is the domain of the amixon® twin-shaft mixer type HM.

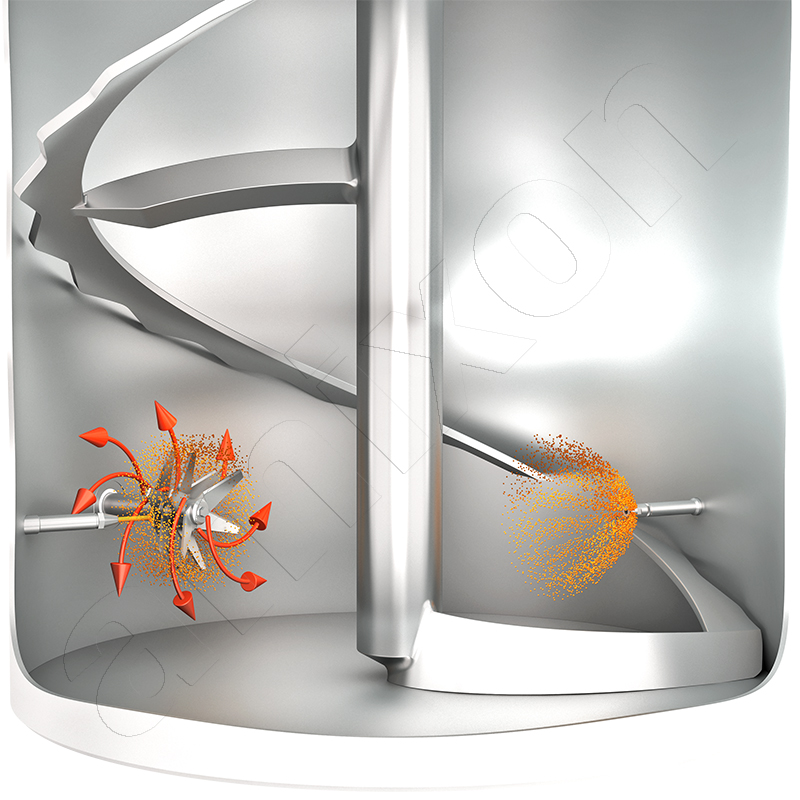

Inject liquids in a targeted manner and distribute them homogeneously

Liquid additives can occasionally produce agglomerates in the baking agent, which should generally be avoided. Agglomerates affect the appearance of the baked product. The way liquids are added during mixing determines the consistency of the mixture.

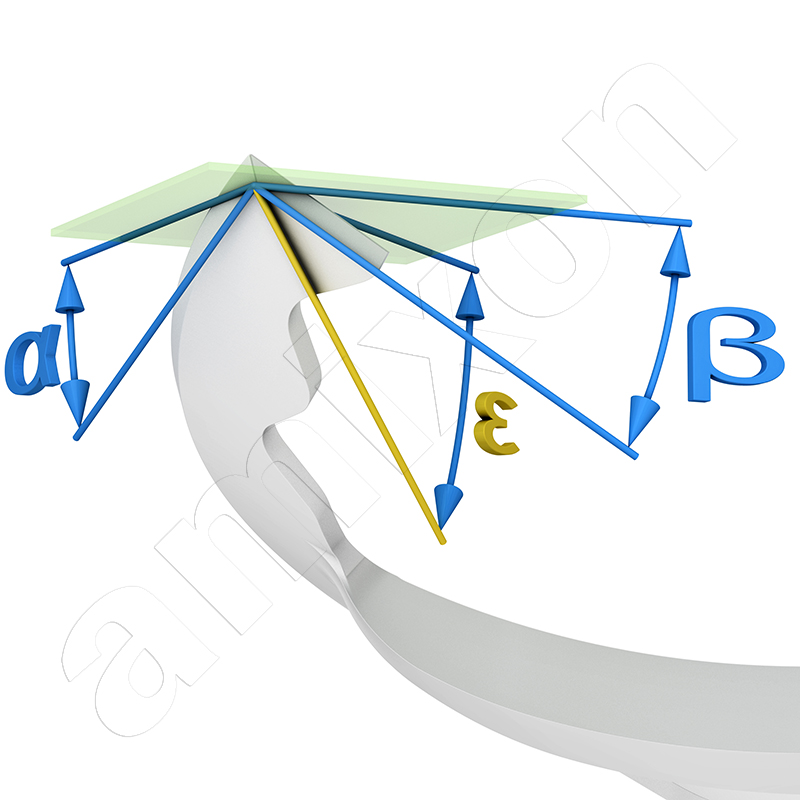

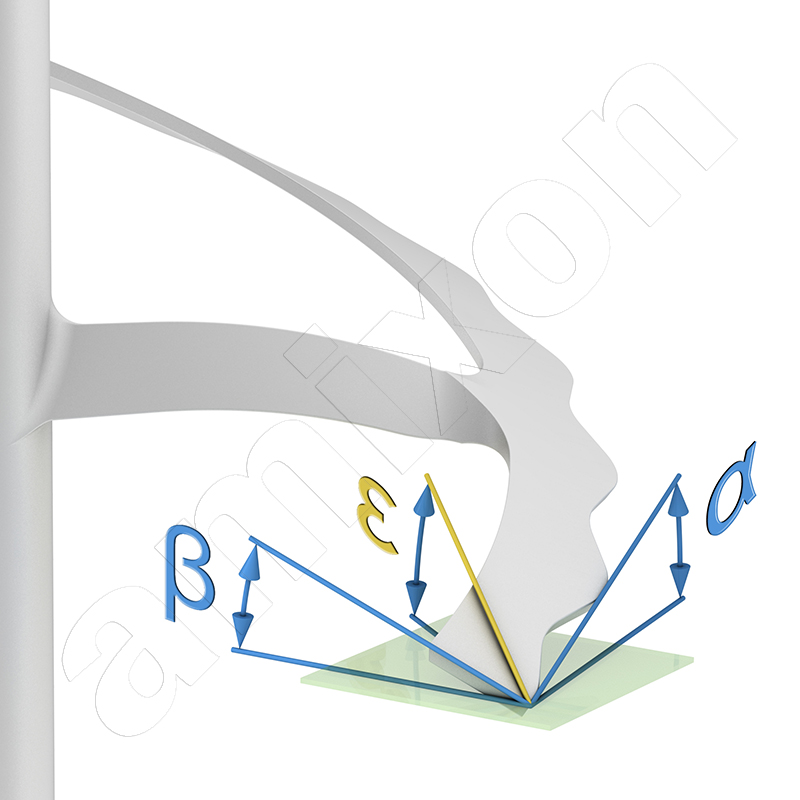

amixon precision mixers offer particular advantages for the user: Some baking agents are wetted only with very small additions of liquid. As a rule, the components of the baking mixture have different affinities for the liquid phase. Some are hydrophilic or even absorbent, others may be hydrophobic. In this case, the distribution of the liquid in the powder is of particular importance, because each particle should be wetted with the proportion of the liquid that corresponds to the formulation. The use of two-substance nozzles is recommended here.

The introduction of highly viscous substances into the powder is also possible with amixon® mixers.

In this context, it is interesting to note that the porosity of the bulk initially increases slightly with low liquid addition.

- The bulk becomes looser,

- the bulk density decreases somewhat

- the dust content decreases and

- the flowability improves slightly.

However, it is usually not trivial to wet a pile with a wide particle size distribution quickly, gently and uniformly. In this context, it is useful to take a closer look at the phenomena of affinity, surface tension, porosity and viscosity.

Baking agents are essential guarantors of consistent baked goods quality

Production conditions and sales success. They represent the highest technological standards, because baking improvers are highly concentrated. They are added to the flour only in a proportion by mass of approx. 1 % to 5 %.

Of course, they must also be distributed accordingly homogeneously in the flour. This homogenizing task is performed by the kneader in the industrial bakery by first mixing flour, sugar, salt, baking agents and seeds in a dry state before the powder mixture is turned into a dough mass by adding water.

Similar to how convenience food preparation has changed individual cooking in the home, the baking supplies industry is also being inventive and simplifying the production steps of baking. Modern baking agents avoid process risks that could jeopardize the success of the finished portioned dough. The dough pieces are delivered either chilled or even frozen. Only the baking then takes place in the oven of the bakery or on the sales floor of the discounter.

Depending on the type of pastry, chilling or freezing involves additional risks because it requires slowing down or interrupting the fermentation of the dough. As a result, the above-mentioned active ingredients have altered properties. Dough rheology may be adversely altered, enzymes may be prematurely inactivated, hydrocolloids lose their ability to bind water in the dough, starch may possibly retrograde, or stale baking makes the baked product appear prematurely unattractive.

If dough pieces are cooled or frozen before baking, both the process technology of dough preparation and the powder formulations must be redeveloped or adapted.

Allergens and intolerances

A number of allergens are of natural origin, they are part of our cultivated plants. Plant protein compounds that can trigger allergies are found, for example, in celery, mustard, sesame seeds, cereals, nuts and beans. It is assumed that these are so-called defense or storage proteins. For example, the oily secretions on apples are a natural protection against spoilage, but in allergy sufferers this protective substance leads to unpleasant swelling of the mucous membranes, eye itching and possibly even asthmatic attacks. But figs, kiwis, peaches and carrots can also contain allergenic proteins. Sometimes it is even the smallest amounts that trigger a spontaneous reaction in allergy sufferers. It should be briefly mentioned at this point that some alpha-amylase enzymes contained in baking agents can also trigger asthma symptoms.

Birch, alder and hazelnut pollen are particularly allergenic and can cause significant discomfort for allergy sufferers in the spring. Many allergy sufferers in this group are particularly at risk of developing food allergies to celery, mustard, sesame seeds, grains, nuts and beans. The interesting thing is that the allergens are destroyed or inactive after cooking. If the above foods or parts thereof are exposed to a baking process, they are also ineffective as allergens. Exceptions are hazelnuts and celery. Highly sensitive allergy sufferers are advised to avoid eating roasted hazelnuts.

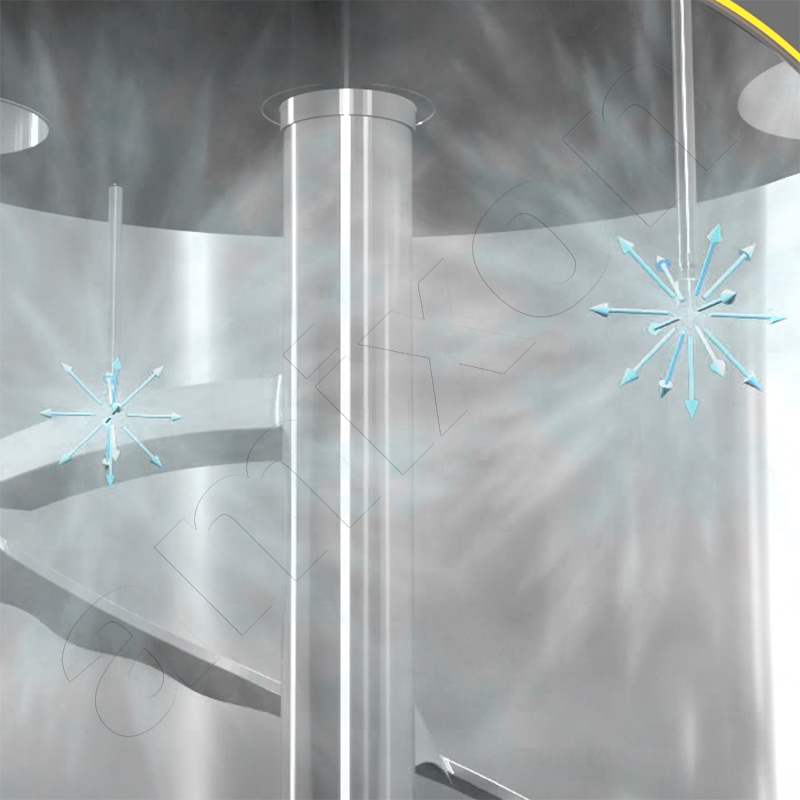

If products containing allergens and products declared as non-allergenic are produced in the same mixer, wet cleaning is unavoidable. Wet cleaning of a "dry mixer" is a challenge. Significant risks may occur.

Differing batch sizes

As in all areas of the value-added industry, a production plant must always be adapted to the structure of the business model. Many things are changing faster today than they used to. What is the best way to adapt to future market demands?

Some trends are already apparent today:

- Customer requirements are becoming more individual and tend to be more complex.

- Customers expect short response times from the supplier.

- Increasingly, smaller order quantities must also be served.

- Baking agents should be free of impurities. It should be ensured that the baking agents ordered do not contain any product carryover and that the ingredients can be clearly declared.

- Allergen-free products should be declared as allergen-free without restriction.

- The baking agents are to be accurately weighed and supplied in customized labeled containers.

- Ideally, the baking agents should be homogeneous, free-flowing, lump-free, low-dust or dust-free.

The above-mentioned customer requirements can be met all the more easily, the better the following accompanying circumstances are:

- there is a large backlog of orders

- Many of these orders are of the same type, so that minor residual contamination is not critical.

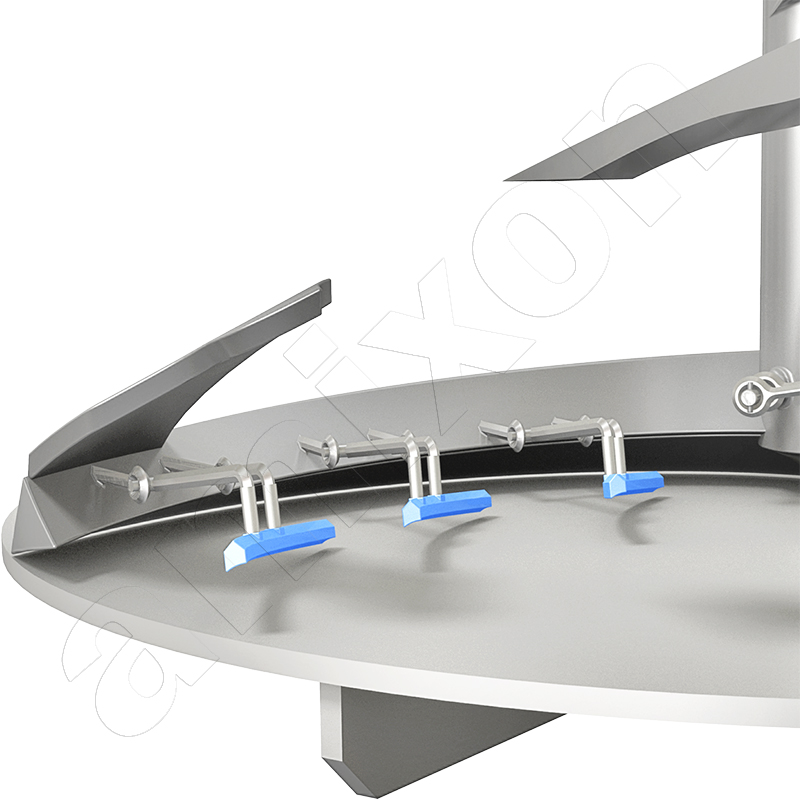

- the mixing plant is able to empty itself almost completely

- The sequence of the individual orders is optimized with regard to the permissible residual contamination.

- all required raw materials are on site and quickly available

Ideally, the computerized order management system should reschedule production several times a day according to the current order situation. Mixed batches with similar ingredients are processed one after the other. Manual dry cleaning is only performed when there is a significant change in ingredients. Key aspects include taste, flavor, odor, color, microbiological challenges, allergens and non-allergens, and ritual cleaning requirements for halal or kosher production.

Wet cleaning is only necessary - if at all - at the end of the production shift.

The above production regime is all the more feasible,

- the better the plant is able to completely drain itself automatically.

- the easier the manual cleaning is

- the easier the wet cleaning can be done

amixon® conical mixers and KoneSlid® mixers have excellent residual discharge characteristics. amixon® flat-bottom mixers also have excellent residual discharge characteristics if SinConcave®, SinConvex® or ComDisc® can be used.

Demonstrations and mixing tests

in Germany at amixon GmbH or at the technical centers in China, India, Japan, South Korea, Thailand or the United States of America.

We show you both mixing and cleaning in excellent form - using your original products. Please contact us. We will be happy to arrange a suitable trial date with you.

© Copyright by amixon GmbH