In German, the term "Tee" is generally understood to cover infusions made from any dried plant derivative. In the Romanic language regions, linguistic differentiation is made between the traditional tea (tea leaf from the Camellia Sinensis), herbal tea, and fruit tea. For example, Rooibos tea is not tea in the traditional sense.

amixon® mixing technology for professional tea preparation

The flavour of tea is influenced by many factors. Region and location of the tea plantation, time of harvest, weather at harvest time, storage, fermentation, transport, packaging, etc.

Whether classic leaf tea or fruit tea, in many cases the aim is to change or improve the flavour. Various methods are available to the industry for this purpose:

- Spraying on a liquid flavouring during blending

- Addition of powdered flavourings during blending

- Adding flavouring additives that are removed from the tea after sufficient diffusion (e.g. citrus peel or pieces of fruit)

In all three cases, the accuracy of the blending process is of great importance. However, it is equally important that the tea particles are not damaged. Under no circumstances should dust be produced. Even when using the diffusion method, gentle homogenisation must take place before the tea is packaged.

amixon® stands for precision and hygiene worldwide. The amixon® mixing process is uniquely gentle and efficient. The mixing process is explained in this article.

The raw materials are homogenised directly on delivery.

Tea houses all over the world process and sell not only the classic green and black teas. They also supply so-called fruit teas. These are dried fruit, vegetable and herb derivatives that are prepared / blended in a similar way to classic tea.

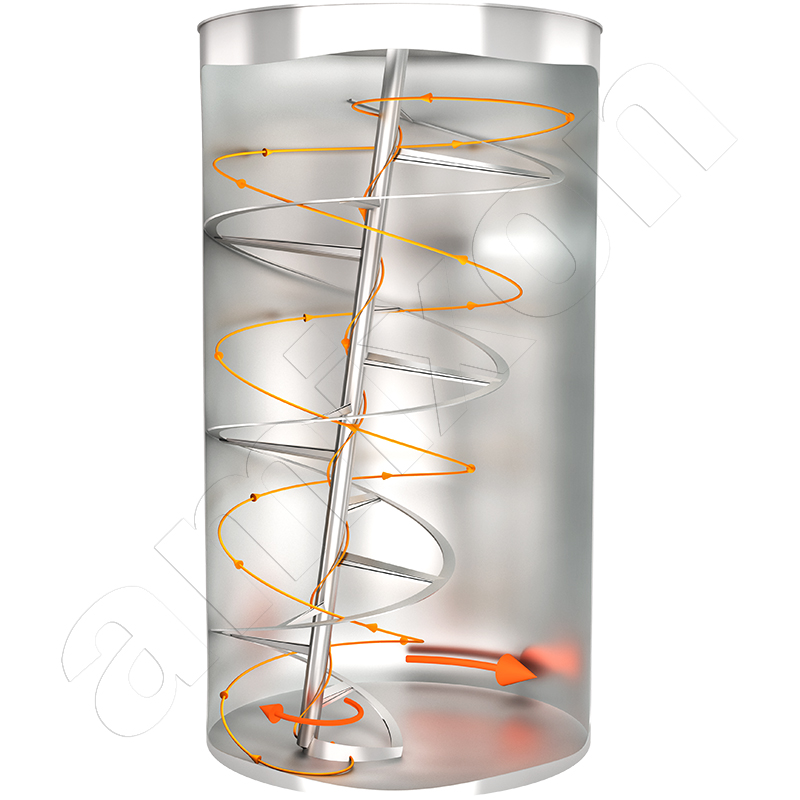

Large quantities are often delivered. These are of varying quality. Silo mixers homogenise the heterogeneous individual batches. For this mixing task, amixon® offers a Gyraton® silo mixer / blender. The mixing tool of the Gyraton® mixer can rotate almost as slowly as required. Nevertheless, ideal mixing qualities are produced.

The mixing / blending mode specifies the time in which a homogeneous mixing result should be achieved. The speed of the Gyraton® mixing tool is based on this. Once the specified time has elapsed, the Gyraton® mixer can discharge the tea without segregation. This special feature of the Gyraton® mixer / blender means that the drive motors can be kept extremely small. This method of operation is particularly gentle on the tea leaves and the dried fruit.

Gyraton® blenders homogenise precisely and gently. They require little drive power.

amixon® twin-shaft mixer for 5 m³. Mixing time only 30 - 60 seconds

Twin-shaft mixers are used for mixing and flavouring tea, herbs and powders.

- Highest mixing quality

- Extremely short mixing times

- Minimal electrostatic charge

- Minimal energy input (preserves the particle shape)

- Universal use for a wide variety of materials (powdery, powdery, lumpy, fibrous agglomerates, good flowing, poor flowing, dry or moist, ....)

- Ideal mixing qualities despite different filling levels

- fast and uniform wetting when liquid flavourings are added or only dust is to be bound

- Fast and complete emptying

- Dry and wet cleaning possible

- Optional automatic cleaning

- Can be optionally sterilised

- Convenient, ergonomic accessibility Large doors

If you produce tea, herbs, spices, luxury foods, flavours, dessert products, cereals, instant products or food supplements, you can rely on the mixing quality of amixon machines.

Our technical centre enables practical trials for small and large batches. The trials provide the user with valuable suggestions. Several process steps can often be combined in one machine.

Twin-shaft mixer in the ‘off-line process’

The amixon® twin-shaft mixer is particularly suitable for larger batches of approx. 2 m³ to 15 m³. Here, too, the focus is on optimising the quality of the mix. The mixing tools are only set in motion after the last powdered formulation component has been added. Liquids are added during the mixing process. Ideal mixing qualities are achieved after 20 to 40 revolutions. The closing valves then open and the finished mixture flows into containers or big bags.

The mix is emptied into 4 containers at the same time. In this case, there are two big bags and two bulk material containers.

The four closing valves of the mixer are called DosiFlap®. These are controlled via the weighing signal of the respective platform scales. The special feature of DosiFlap® is that it seals the mixing chamber without any dead space.

This ensures that the mixing batch is evenly portioned. Filling is fast. Only a small amount of vertical installation space is required. The mixer empties itself 99.98%.

Big bags and bulk containers are transported to the filling machine.

With batch-wise ‘offline mixing’, the mixing process is decoupled from the filling process. This makes the mixing operation flexible: while the filling machine is filling cans, bags, sachets and tea bags, the mixer can already be cleaned and prepared for the next mixing job.

The advantages of the amixon® twin-shaft mixer for the user are as follows:

- Ideal mixing qualities with very short mixing times. Particularly gentle mixing process.

- Space-saving design, particularly suitable for large batches.

- Only one quality analysis and one retention sample per large batch.

- The DosiFlap® sealing valve can be used as an option. It allows the outflowing mix to be throttled and stopped at any time.

- Emptying is extremely fast, optionally in up to four containers simultaneously. Particularly effective residual emptying of up to 99.98% using ComDisc® discharge tools.

- Filling levels can vary from approx. 15% to 100% with this mixer.

- Highest hygiene standards. Large inspection doors close without dead space, permanently gas-tight.

- On request, the mixing chamber complies with dust EX zone 20. The mixer can be manufactured to be pressure shock-resistant, pressure-resistant or vacuum-resistant.

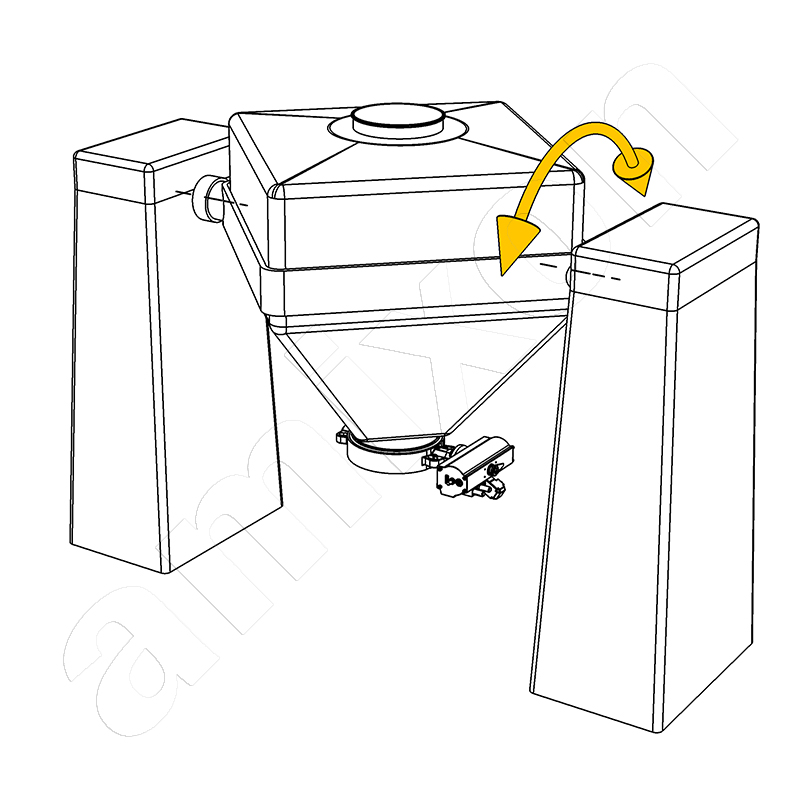

KoneSlid® mixer for end-of-line mixing (batch-in-line processing)

The KoneSlid® mixer from amixon® has been developed especially for food companies that mix in batches and use the "end of the line" production concept. In this process, all processing units are arranged one below the other. The finished mixture flows from the mixer via the secondary container directly into the packaging machine.

KoneSlid® mixers are manufactured in sizes between 300 and 3000 liters. The KoneSlid® mixer mixes very precisely and extremely gently at low speed. In addition, the mixing time is particularly short. The design of the mixer ensures that even sensitive agglomerates, for example from the spray tower, fluidized bed granulation or vacuum freeze-drying, are retained.

The mixer can also be designed to be vacuum-tight on request. This means that the atmospheric oxygen can be removed from the porosity of the powder mixture during the mixing process by applying a vacuum. Saturation is achieved by introducing a suitable inert gas.

Discharge takes place without segregation in just a few seconds.Free-flowing products flow out completely, so that cross-contamination is largely eliminated.This makes the KoneSlid mixer ideal for batchwise mixing of "end of the line" products.

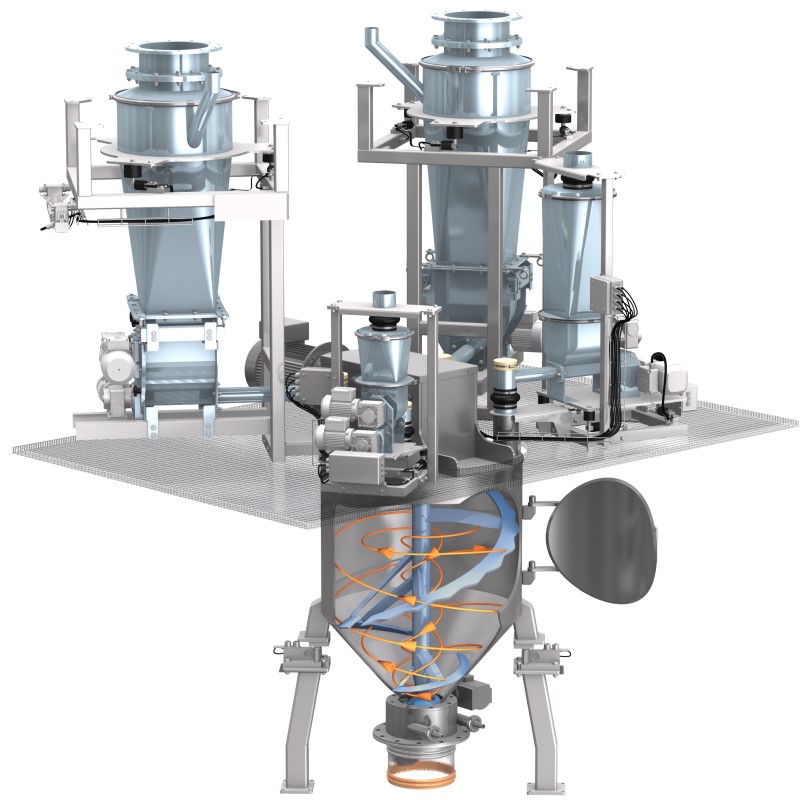

Continuously mixing/flavouring tea, herbs, foodstuffs

Mixing at the end of the line can be done in batches or continuously. The conical mixer shown here can do both. The continuous mixing process shown here also delivers a very high mixing quality. It is important that the continuous dosing of the components is exact.

Tea leaves, herbs, chopped pieces of vegetables, fruit and spices, powdered flavourings and liquid flavourings are continuously fed into the mixer. Mixing takes place in a continuous boiler flow. This guarantees a homogeneous end product. The continuous bowl flow in the amixon® conical mixer is excellent at compensating for short-term dosing errors. In addition, there is no product loss when a mixing campaign starts or ends.

The mix is discharged continuously and without segregation. This makes the amixon® Continuous Mixer AMK ideal for continuous mixing ‘End Of The Line’. The products flow directly into the packaging machine.

Mixing tests, steam sterilisation, disinfection

amixon® has more than 30 test mixers. From 10 litres to 4000 litres. Including pressure sterilisers and synthesis reactors. A visit to the amixon® technical centre is also of interest to you if you are looking for good solutions. We cordially invite you. Bring your problem raw materials with you.

Process plants based on vertical precision mixers are often an excellent source of inspiration for your own product development.

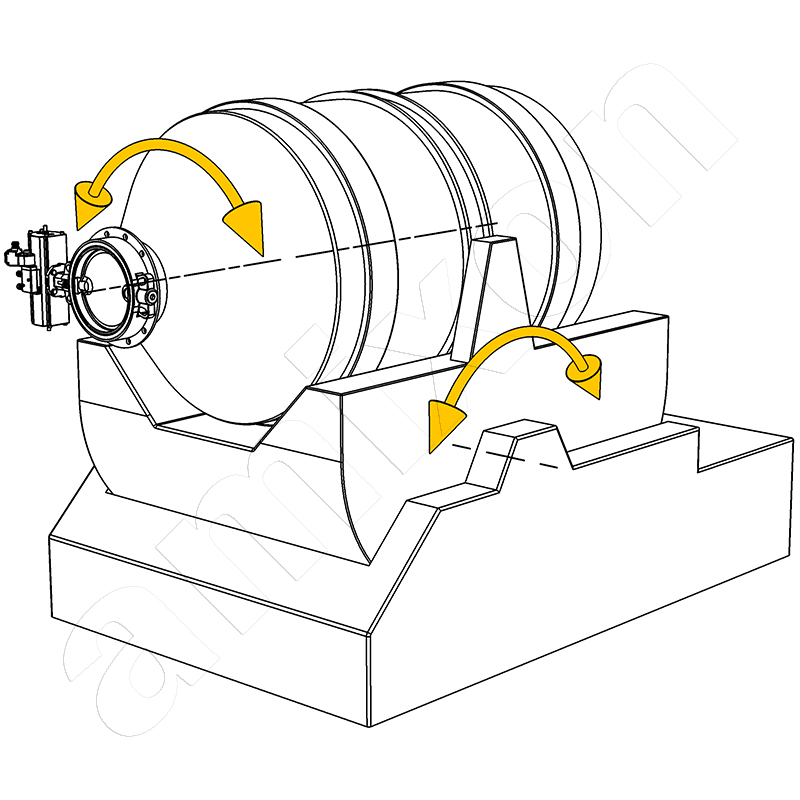

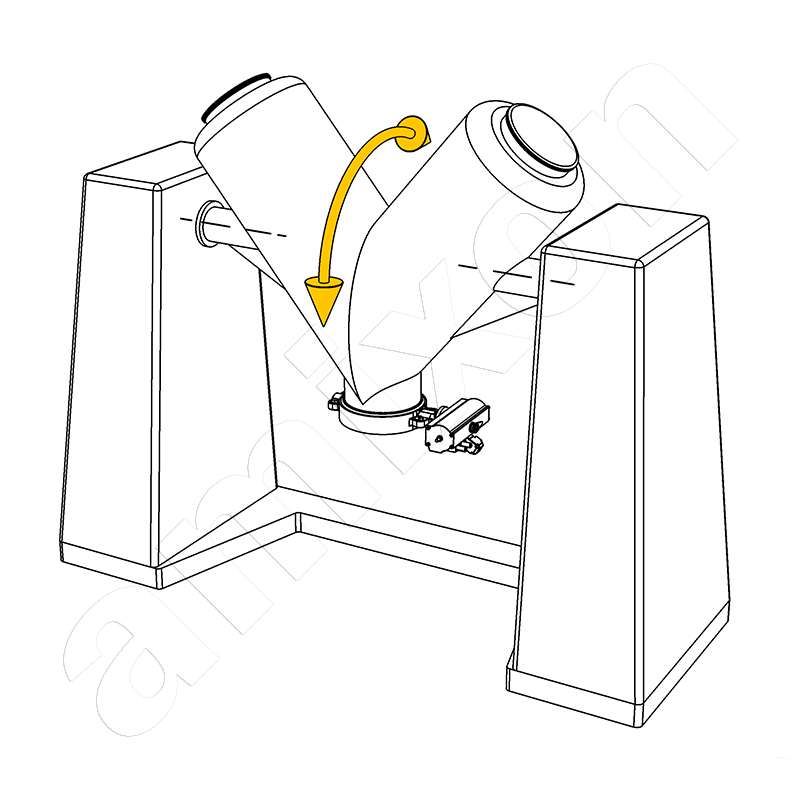

Rotary tube mixer is replaced by amixon® technology.

History of tea

When reading about the cultural and historical background of tea, the layman may recognise one or two parallels with viticulture. Both vines and tea bushes (Darjeeling) grow on steep slopes. Their fruit has to be picked by hand. For one kilogramme of Assam tea, for example, more than 10,000 leaves have to be picked.

Tea is a cultural asset

Both the grapevine and the tea bush are cultural assets that have been cultivated for thousands of years. Both plant species can reach a great age. Both vineyards and tea gardens require a great deal of care to ensure yields. Black tea and wine are produced through fermentation. Like the enjoyment of a good wine, a good tea can also tantalise our senses. It conveys a feeling of well-being and relaxation.

Purity

Weeds must be constantly removed as they can spread rapidly as angiosperms. Weeds can contain natural toxins. These are pyrrolizidine alkaloids. Like pesticide residues, they must not contaminate the harvested crop.

According to ISO standard 3720, only the leaves of the Camellia Sinensis plant may be labelled as tea.

Tea as a commercial product

Tea is a high-value commodity. Around 6.1 million tonnes of tea were harvested worldwide in 2017, with China and India being the largest producers with 40 per cent and 22 per cent respectively, followed by Kenya with 7 per cent, Sri Lanka with 6 per cent and Turkey and Vietnam with 4 per cent each. The three largest tea importers are Pakistan, Russia and the USA. According to Wikipedia, per capita consumption in Europe is highest in East Frisia, followed by the UK, Ireland and Poland. In addition to the stimulating effect and the colour of the infusion, it is the taste and smell that make tea enjoyable.

Free-fall mixers are replaced by amixon® technology.

V-mixer / free-fall mixer is replaced by amixon® technology.

Long supply chains

Fermentation is a quality-determining step. After harvesting, the tea leaves are milled, releasing moisture through the plant's own enzymes. In the presence of oxygen, fermentation is set in motion. The tea leaves change colour and aroma. Fermentation is stopped by adding dry hot air or steam. A short fermentation period produces green tea, a longer fermentation period produces black tea. An ideal degree of drying typical of the variety is then set for packaging and safe transport. The storage environment should be cool and dry.

The publication ISO 3720 2011-04 and the guidelines of the German Tea Association deal with quality issues in tea production from the tea garden to the consumer.

© Copyright by amixon GmbH