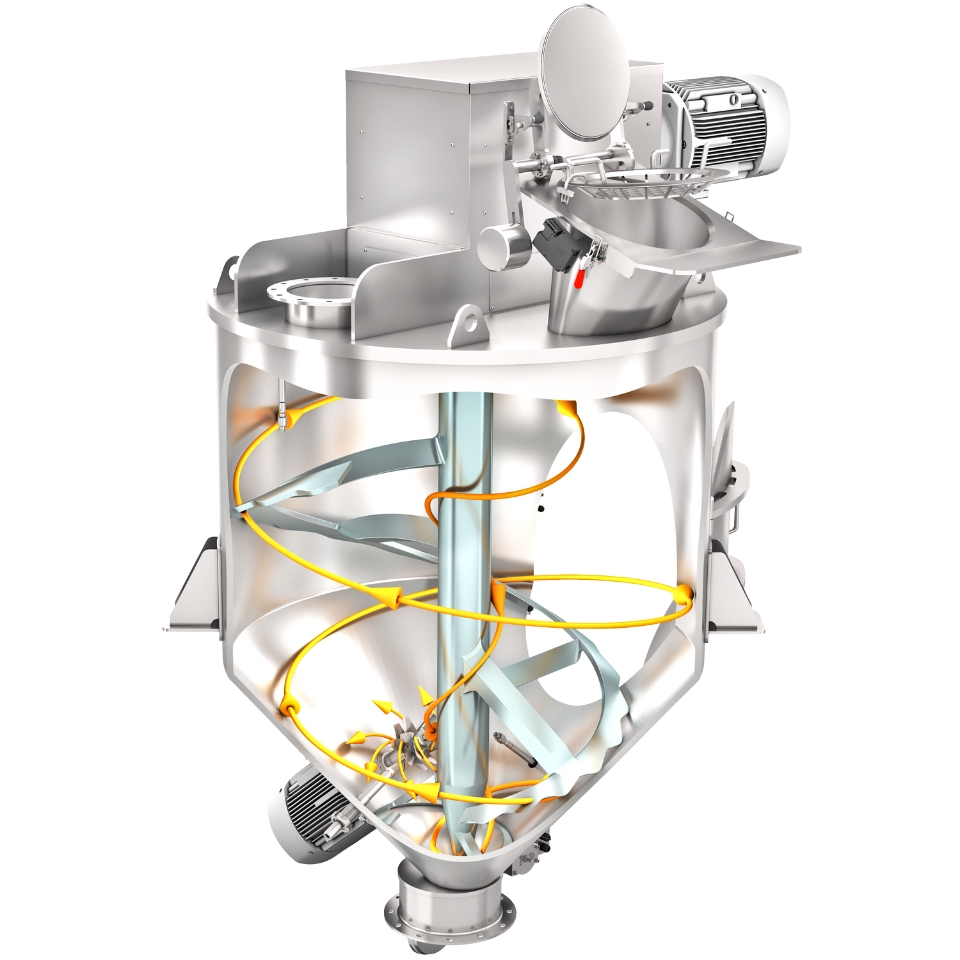

Continuous mixer (AMK)

Further characteristics of the continuous mixer:

- Technically ideal mixing quality

- Option between operation as batch mixer or continuous mixer

- Adjustable mixing intensity (from gentle homogenization to intensive deagglomeration)

- No product loss at start and/or end of production

- Micro-fine admixture of liquid material without contamination of the mixer

- Specific filling level selection from 10% to 80% of cubic capacity

- Ideal emptying of residues on the continuous mixer

- Extended process including: moistening, tempering, drying, reaction processing

- Mixing device mounted only on top

- Safe cleaning; dry or wet

The mixer can be designed to comply with the highest regulatory and hygiene standards: GMP, FDA, and 3-A Sanitary Standards. It also meets EHEDG requirements.

Continuous mixing with the aid of the continuous boiler flow:

The discharge valve of the mixer is closed. All the gravimetric working dosing components are started simultaneously with small mass flow and tune themselves automatically in relation to each other.

The level of the mixing vessel fills up continuously, starting up the mixer when it reaches half capacity. Tuning is completed once the mixer is filled to half its capacity approximately. The discharge device opens slowly once the mixer is filled at approx. 80 % of working capacity. A filling level of 80 % is kept constant. The dosing flows are increased up to the maximum mass flow while maintaining a constant synchronisation.

Operation at end of production

All dosing components gradually slow down the mass flow and then switch off at the same time. The continuous mixer discharges the mixture continuously until it is completely empty.

Learn more about the common applications of continuous powder mixing, and its advantages and disadvantages compared with batch mixing.