Production of Pesticides (Part 1)

The production of crop protection products requires modern processing plants. This is because the highly effective substances are valuable. On the one hand because of the high development costs, and on the other because of the complex production process.

At the end of the final synthesis step, a liquid or powdered chemical is produced. Due to its high concentration, it can only be handled in closed systems (pressure and vacuum-tight). Before it is commercialised, it is diluted/diluted and elaborately formulated. This takes into account the health protection of the user. For reasons of longer shelf life and lower transport volume, the powder form is increasingly favoured.

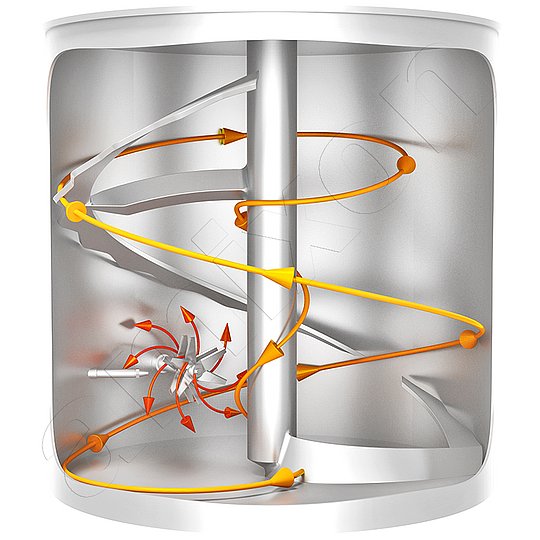

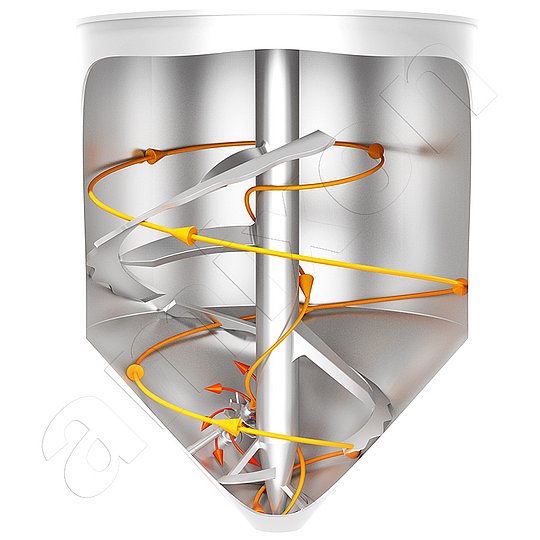

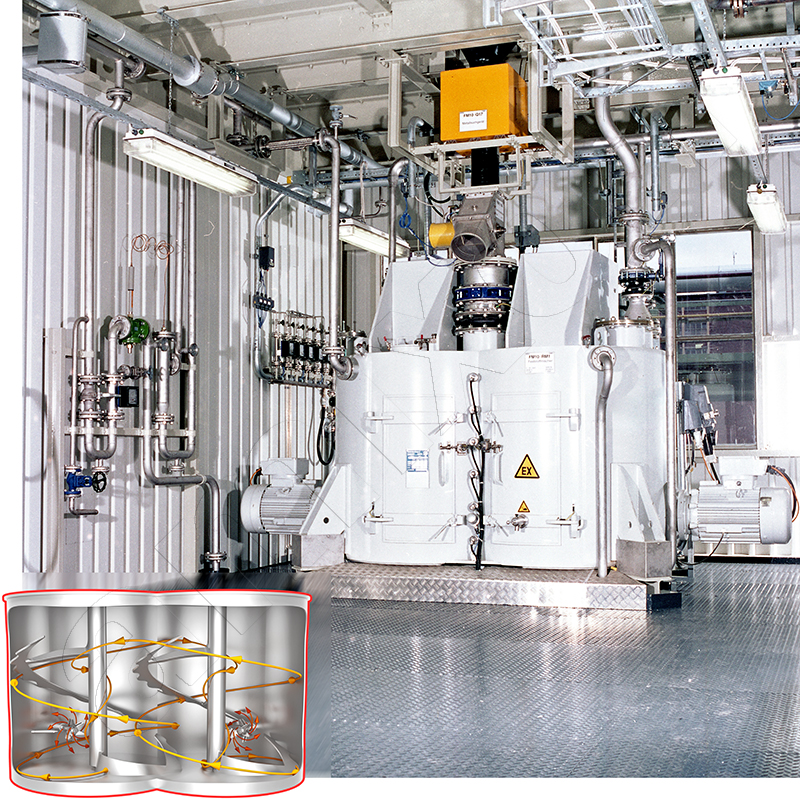

amixon® has developed vacuum mixer dryers that dry particularly quickly and gently. The powder is usually free-flowing, crystalline and low in dust.

This two-part article describes typical amixon® design features for greater efficiency:

- very low drying temperature

- accelerated heat input

- faster drying

- Less shear stress on the product

- preservation of the particle structure

- better residual emptying

- Recovery of solvents

The respective synthesis stage is completed with vacuum drying

Vacuum drying provides a powdery synthesis product. This serves as a starting material for a further synthesis step. Modern, highly effective powder chemicals are usually the result of several synthesis steps, which almost always end with vacuum mixed drying. With each synthesis step, the active ingredient becomes more valuable and often more sensitive. It is therefore important to avoid thermal and mechanical stress during drying.

Once the synthesis product is dry and cool enough to be discharged from the vacuum dryer, simple stainless steel materials such as 1.4571 or 1.4404 are usually sufficient.

An important part of active ingredient development concerns the final product formulation: one of these is, for example, the micronisation of powdered active ingredients and their subsequent agglomeration. Agglomerated products are fixed in their mixed state, low in dust and easily suspended/soluble in water. In contrast, small individual particles would float permanently on the water without sedimenting. Only a lump-free, homogeneous suspension/solution can be applied evenly by the farmer.

Another quality aspect is long-term stability. No matter in which climate zone of the world the plant protection product is used. It must not decompose and must be easily soluble/dispersible.

In the amixon® technical centre, the preparation steps of synthesis, vacuum contact drying, homogenisation and pelletisation can be demonstrated. amixon has decades of experience in the design of process machines that are 10 to 50 times larger than the test machines.

Vacuum drying provides a powdery synthesis product. This serves as a starting material for a further synthesis step. Modern, highly effective powder chemicals are usually the result of several synthesis steps, which almost always end with vacuum mixed drying. With each synthesis step, the active ingredient becomes more valuable and often more sensitive. It is therefore important to avoid thermal and mechanical stress during drying.

Once the synthesis product is dry and cool enough to be discharged from the vacuum dryer, simple stainless steel materials such as 1.4571 or 1.4404 are usually sufficient.

An important part of active ingredient development concerns the final product formulation: one of these is, for example, the micronisation of powdered active ingredients and their subsequent agglomeration. Agglomerated products are fixed in their mixed state, low in dust and easily suspended/soluble in water. In contrast, small individual particles would float permanently on the water without sedimenting. Only a lump-free, homogeneous suspension/solution can be applied evenly by the farmer.

Another quality aspect is long-term stability. No matter in which climate zone of the world the plant protection product is used. It must not decompose and must be easily soluble/dispersible.

In the amixon® technical centre, the preparation steps of synthesis, vacuum contact drying, homogenisation and pelletisation can be demonstrated. amixon has decades of experience in the design of process machines that are 10 to 50 times larger than the test machines.

Multi-stage production process with high requirements

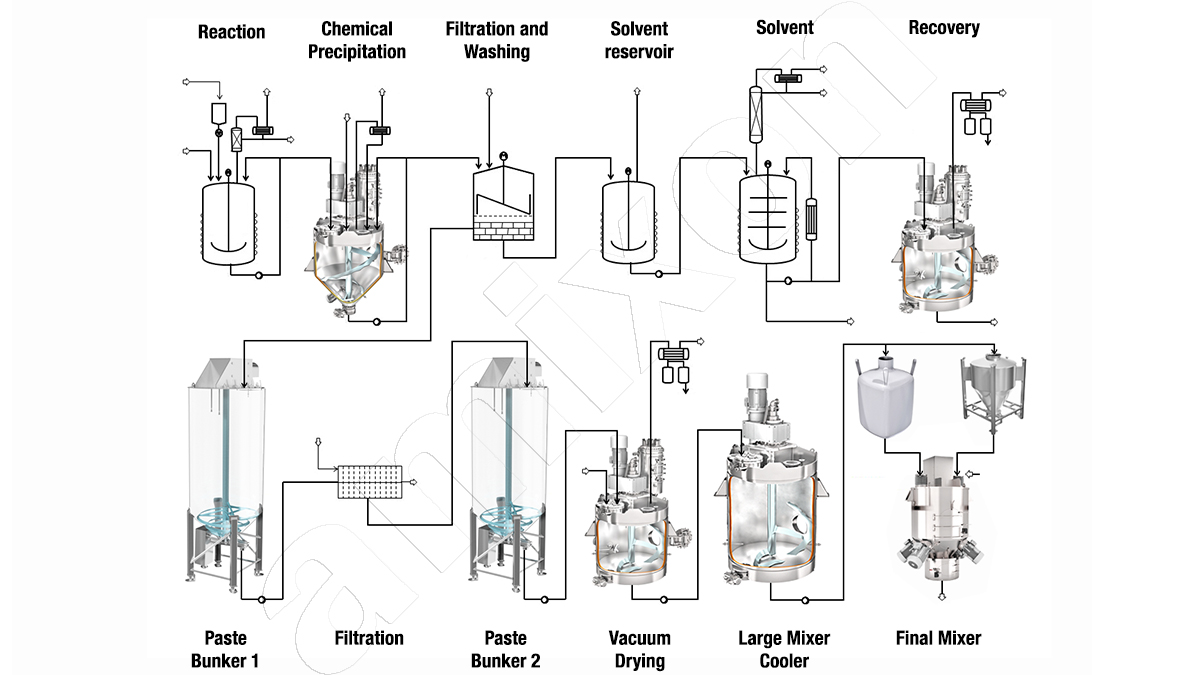

The synthesis steps for the production of plant protection products differ depending on the active ingredient and the desired form of application. However, the basic process steps are similar for powdered starting materials.

Firstly, a solvent is introduced into the reactor, the powdered starting materials are added and homogeneously dissolved or suspended. The first synthesis reaction takes place in this liquid. The stirring process can be supported by circulation pumps to promote the reaction kinetics. Once the reaction is complete, the new substance is available in liquid form.

Additives are added to the liquid to initiate crystallisation of the new intermediate. The crystallisation/flocculation is supported by clever temperature control. A particularly gentle mixing action is required during the phase transition (liquid to crystalline/solid). This favours the preservation of the crystalline particle structure.

https://www.youtube.com/watch?v=StPGmvy-i4E

The suspended solids generally remain pumpable and are subjected to a multi-stage wash in the next process step. Here, the active ingredient crystals are freed from the reagents using water or solvent. Mechanical solid-liquid separation is carried out using centrifuges.

Occasionally, vacuum filters or chamber filter presses are also used. As a rule, gas-tight, closed systems are favoured for mechanical solid-liquid separation.

This first synthesis step is completed by thermal drying in the amixon® vacuum mixer dryer. The drying process is controlled in such a way that the particle structure is optimally preserved. In addition, the aim is to recover the solvents.

The synthesis steps for the production of plant protection products differ depending on the active ingredient and the desired form of application. However, the basic process steps are similar for powdered starting materials.

Firstly, a solvent is introduced into the reactor, the powdered starting materials are added and homogeneously dissolved or suspended. The first synthesis reaction takes place in this liquid. The stirring process can be supported by circulation pumps to promote the reaction kinetics. Once the reaction is complete, the new substance is available in liquid form.

Additives are added to the liquid to initiate crystallisation of the new intermediate. The crystallisation/flocculation is supported by clever temperature control. A particularly gentle mixing action is required during the phase transition (liquid to crystalline/solid). This favours the preservation of the crystalline particle structure.

https://www.youtube.com/watch?v=StPGmvy-i4E

The suspended solids generally remain pumpable and are subjected to a multi-stage wash in the next process step. Here, the active ingredient crystals are freed from the reagents using water or solvent. Mechanical solid-liquid separation is carried out using centrifuges.

Occasionally, vacuum filters or chamber filter presses are also used. As a rule, gas-tight, closed systems are favoured for mechanical solid-liquid separation.

This first synthesis step is completed by thermal drying in the amixon® vacuum mixer dryer. The drying process is controlled in such a way that the particle structure is optimally preserved. In addition, the aim is to recover the solvents.

The development of new crop protection products is lengthy and costly

It takes around ten years of intensive development work before a crop protection product is launched on the market. New substances are constantly being sought in the laboratory and tested in model trials.

The manufacturer invests around 200 million euros in the development of a new active ingredient. Around 200 studies are carried out and more than 800 parameters are recorded.

Health and safety at work are the top priority. Each new test substance is formulated in such a way that it can be used safely in agriculture. For these formulations, so-called carriers such as rock flours or organic solvents are used as excipients. Surface-active emulsifiers are used as wetting or adhesion agents. The task of the formulation excipients is to make the active ingredients technically safe for the final application. Excipi

It takes around ten years of intensive development work before a crop protection product is launched on the market. New substances are constantly being sought in the laboratory and tested in model trials.

The manufacturer invests around 200 million euros in the development of a new active ingredient. Around 200 studies are carried out and more than 800 parameters are recorded.

Health and safety at work are the top priority. Each new test substance is formulated in such a way that it can be used safely in agriculture. For these formulations, so-called carriers such as rock flours or organic solvents are used as excipients. Surface-active emulsifiers are used as wetting or adhesion agents. The task of the formulation excipients is to make the active ingredients technically safe for the final application. Excipi

Long-lasting synthesis reactors thanks to suitable materials

If we look at the apparatus specifications for new apparatus in synthesis plants in Europe, China, the USA and India, three observations can be made:

- Chemical synthesis processes are becoming increasingly complex.

- The substances obtained are becoming increasingly temperature-sensitive.

- The solvents used are becoming more aggressive/corrosive.

- The hygienic requirements are increasing.

- For safety reasons, ever higher operating pressures and permissible operating temperatures are being defined.

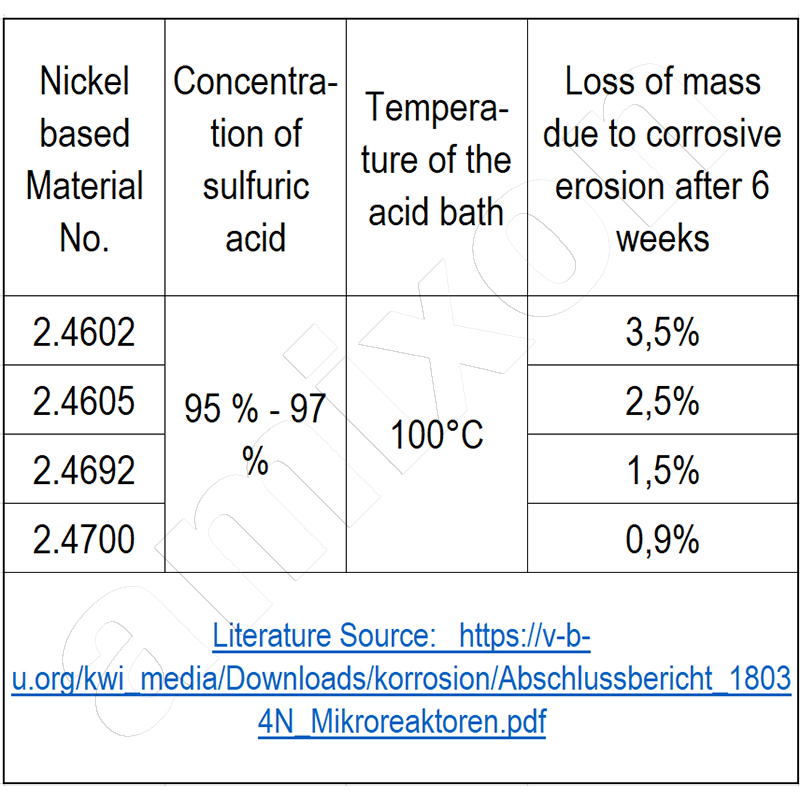

Conventional austenitic materials are still used in the powder sector at best. However, austenitic-ferritic stainless steels (duplex and super duplex steels) are also increasingly being used here. For synthesis reactors and dryers, the trend is towards high-alloy nickel-based materials (Hastelloy C22 and Alloy 59).

Ageing is accelerated by abrupt changes between vacuum and pressure as well as between hot and cold operation. The ageing process can lead to stress corrosion cracking.

amixon® has many years of experience and the necessary welding qualifications to manufacture pressure equipment of all classes in accordance with international regulations. The average service life of amixon® equipment is more than 30 years. At the same time, amixon® fulfils three requirements:

- Sophisticated design for permanent tightness under pressure and vacuum.

- Excellent corrosion protection.

- High wear protection.

amixon® has welding experience in dealing with high-alloy materials. Welding these materials requires, for example, strict welding sequences and strict cleanliness. Even the mechanical tests and corrosion tests that accompany production, such as ASTM G48, can lead to an unwanted cancellation of the work that has already been carried out. The same applies to the Cabot corrosion test on weld seams.

If we look at the apparatus specifications for new apparatus in synthesis plants in Europe, China, the USA and India, three observations can be made:

- Chemical synthesis processes are becoming increasingly complex.

- The substances obtained are becoming increasingly temperature-sensitive.

- The solvents used are becoming more aggressive/corrosive.

- The hygienic requirements are increasing.

- For safety reasons, ever higher operating pressures and permissible operating temperatures are being defined.

Conventional austenitic materials are still used in the powder sector at best. However, austenitic-ferritic stainless steels (duplex and super duplex steels) are also increasingly being used here. For synthesis reactors and dryers, the trend is towards high-alloy nickel-based materials (Hastelloy C22 and Alloy 59).

Ageing is accelerated by abrupt changes between vacuum and pressure as well as between hot and cold operation. The ageing process can lead to stress corrosion cracking.

amixon® has many years of experience and the necessary welding qualifications to manufacture pressure equipment of all classes in accordance with international regulations. The average service life of amixon® equipment is more than 30 years. At the same time, amixon® fulfils three requirements:

- Sophisticated design for permanent tightness under pressure and vacuum.

- Excellent corrosion protection.

- High wear protection.

amixon® has welding experience in dealing with high-alloy materials. Welding these materials requires, for example, strict welding sequences and strict cleanliness. Even the mechanical tests and corrosion tests that accompany production, such as ASTM G48, can lead to an unwanted cancellation of the work that has already been carried out. The same applies to the Cabot corrosion test on weld seams.

Cultivated plants for nutrition

More than 7.8 billion people would be living on Earth by the end of 2020. In 2050, there will be around 9.7 billion people, according to the current UN population projection of 2019. In order to produce enough food for the growing world population, the agricultural industry worldwide cannot function without pesticides. Without crop protection products, the agricultural yields we take for granted around the world today would be nowhere near achievable.

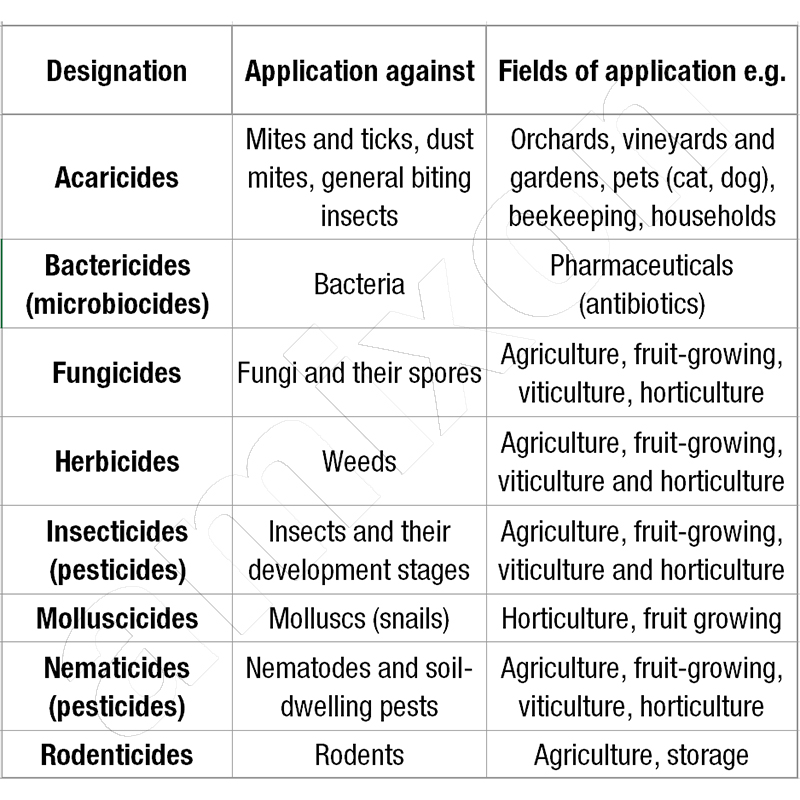

The term pesticides is a collective term and includes active substances with different spectrum of action: to control mites (arcricides), microbial pathogens (bactericides), fungi or their spores (fungicides), multivorous weeds (herbicides), insect swarms (insecticides), nematodes (nematicides) and harmful rodents (rodenticides).

More than 7.8 billion people would be living on Earth by the end of 2020. In 2050, there will be around 9.7 billion people, according to the current UN population projection of 2019. In order to produce enough food for the growing world population, the agricultural industry worldwide cannot function without pesticides. Without crop protection products, the agricultural yields we take for granted around the world today would be nowhere near achievable.

The term pesticides is a collective term and includes active substances with different spectrum of action: to control mites (arcricides), microbial pathogens (bactericides), fungi or their spores (fungicides), multivorous weeds (herbicides), insect swarms (insecticides), nematodes (nematicides) and harmful rodents (rodenticides).

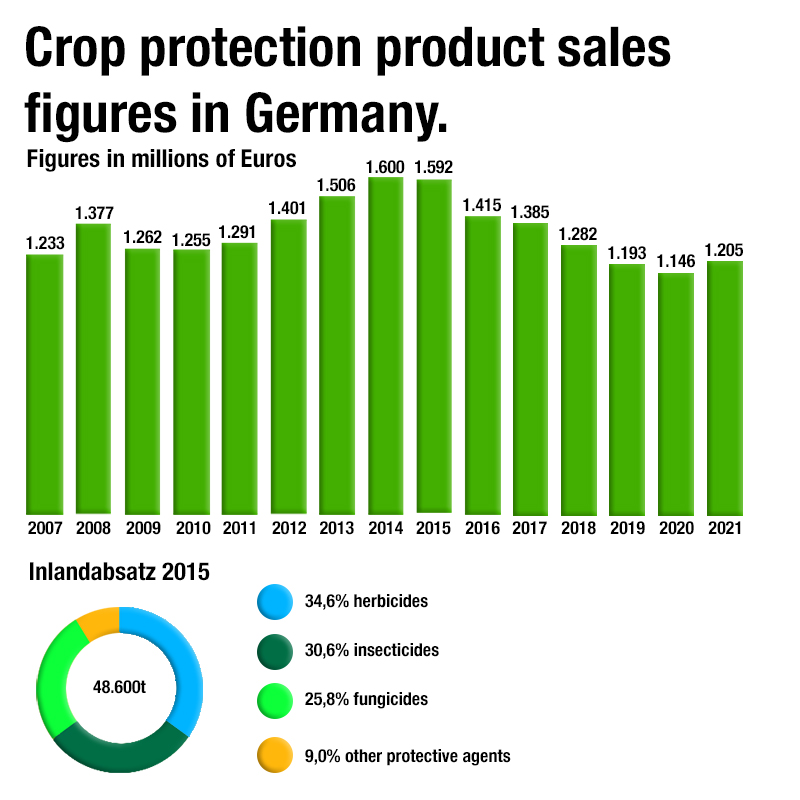

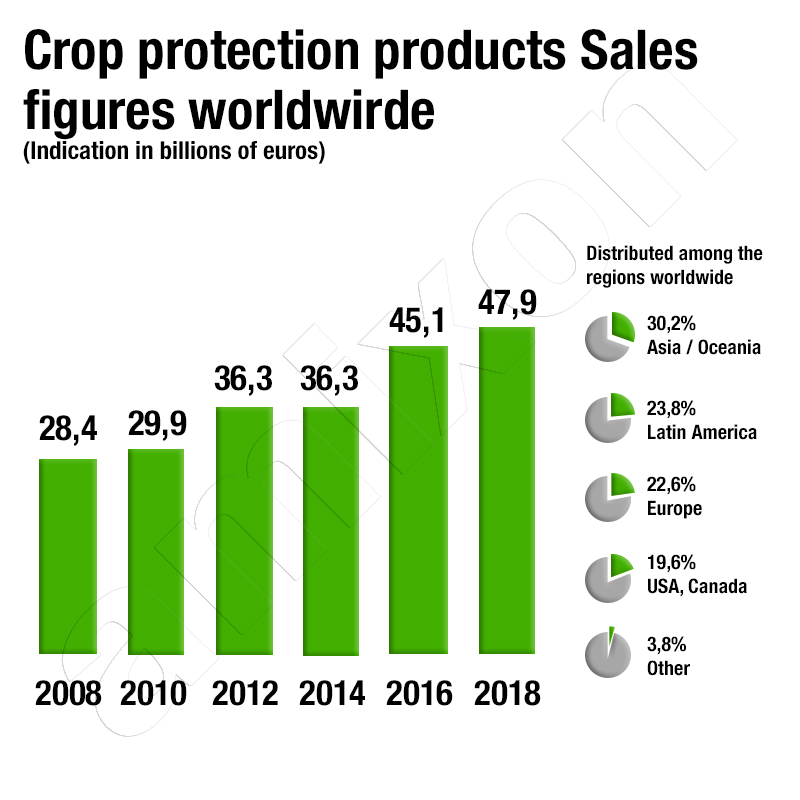

Turnover and sales in the German market for crop protection products,

used against undesirable organisms to maximise yields in agriculture. Unfortunately, their large-scale use also entails residual risks for the environment, but there is no alternative because of their high benefit for agricultural production. Their effect is so great that certain plant protection products may also be used in organic farming. This is the case when other interventions fail. - A frequently practised method is the establishment of clever crop rotations to prevent the mass reproduction of pests -. The range of pesticides that are permitted for use in organic farming, for example, is set out in the Organic Farming Regulation. "In the event of an identified threat to crops, only plant protection products authorised for use in organic production in accordance with Article 16 may be used" (Article 12 of Regulation 834/2007).

used against undesirable organisms to maximise yields in agriculture. Unfortunately, their large-scale use also entails residual risks for the environment, but there is no alternative because of their high benefit for agricultural production. Their effect is so great that certain plant protection products may also be used in organic farming. This is the case when other interventions fail. - A frequently practised method is the establishment of clever crop rotations to prevent the mass reproduction of pests -. The range of pesticides that are permitted for use in organic farming, for example, is set out in the Organic Farming Regulation. "In the event of an identified threat to crops, only plant protection products authorised for use in organic production in accordance with Article 16 may be used" (Article 12 of Regulation 834/2007).

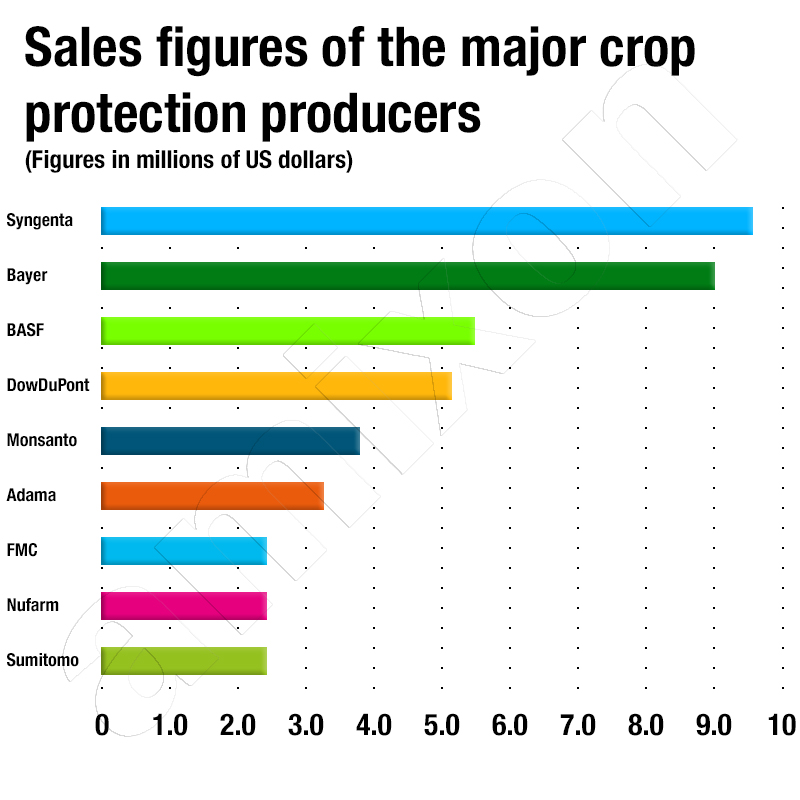

Crop protection products are a global market worth billions

The world market for crop protection products is large. Herbicides account for by far the largest production volume, followed by insecticides and fungicides. In 2018, global sales of crop protection products amounted to just under 48 billion euros - an increase of 0.5 percent compared to the previous year. In 2021, global turnover stagnated. Asia is by far the largest market, ahead of Latin America and Europe.

In Germany, turnover in the same period was 1.3 billion euros. The quantity of plant protection products sold in Germany was around 48,000 tonnes in 2016, doubling within ten years (2006: around 32,000 tonnes). Of these, about 40 per cent are herbicides (weed killers), about 25 per cent are fungicides (against fungi and their spores) and about 30 per cent are insecticides (to kill, drive away or inhibit insects and their developmental stages). The use of plant protection products in Germany declined steadily from 1.6 billion euros to 1.15 billion euros in the period 2014 to 2020. In 2021, consumption increased to 1.2 billion euros. In Germany, around 270 active substances were registered in a total of 753 different plant protection products in 2016. Researchers around the world are working at full speed to develop new, sustainable active substances that break down without leaving residues once they have taken effect.

The world market for crop protection products is large. Herbicides account for by far the largest production volume, followed by insecticides and fungicides. In 2018, global sales of crop protection products amounted to just under 48 billion euros - an increase of 0.5 percent compared to the previous year. In 2021, global turnover stagnated. Asia is by far the largest market, ahead of Latin America and Europe.

In Germany, turnover in the same period was 1.3 billion euros. The quantity of plant protection products sold in Germany was around 48,000 tonnes in 2016, doubling within ten years (2006: around 32,000 tonnes). Of these, about 40 per cent are herbicides (weed killers), about 25 per cent are fungicides (against fungi and their spores) and about 30 per cent are insecticides (to kill, drive away or inhibit insects and their developmental stages). The use of plant protection products in Germany declined steadily from 1.6 billion euros to 1.15 billion euros in the period 2014 to 2020. In 2021, consumption increased to 1.2 billion euros. In Germany, around 270 active substances were registered in a total of 753 different plant protection products in 2016. Researchers around the world are working at full speed to develop new, sustainable active substances that break down without leaving residues once they have taken effect.

Find further information here:

© Copyright by amixon GmbH