Starch extraction and starch preparation

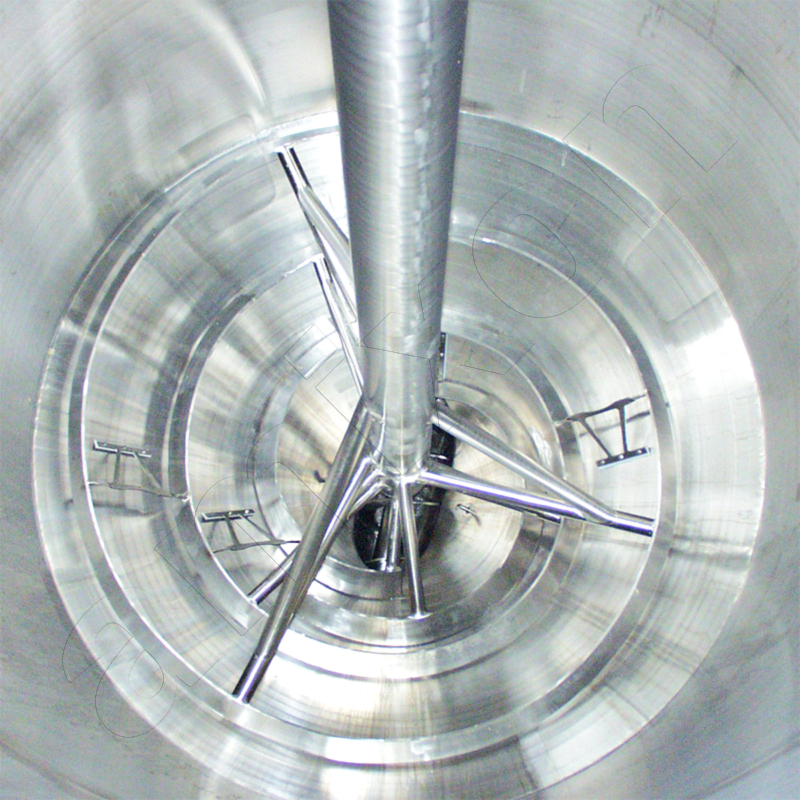

In the amixon® process reactor, you can mix and thermally treat your starch derivatives in a variety of ways. Both heat transfer and mass transfer take place very quickly in large amixon® appliances. There are two reasons for this:

- amixon® offers an excellent mixing effect and

- the specific Heat transfer surface is extremely large.

With the adjustable process parameters of system pressure, temperature, sequential material addition (dry, wet or gaseous) and mixing intensity, you can achieve the desired material conversion. Thanks to the dead-space-free mixing effect, starch modifications in the amixon® synthesis reactor are reproducible, regardless of the rheological properties of the substances. The final vacuum mix-drying process can easily take place in the same amixon® apparatus. It then functions as a high-performance vacuum contact dryer.

amixon® has extensive experience in handling highly viscous products (whether dilatant, structurally viscous or tixotropic). amixon® equipment stands for reliable reaction control. Regardless of whether the processing (mixing, reacting, suspending, deagglomerating, coating, conditioning, vacuum contact drying) is carried out in small or large batches.

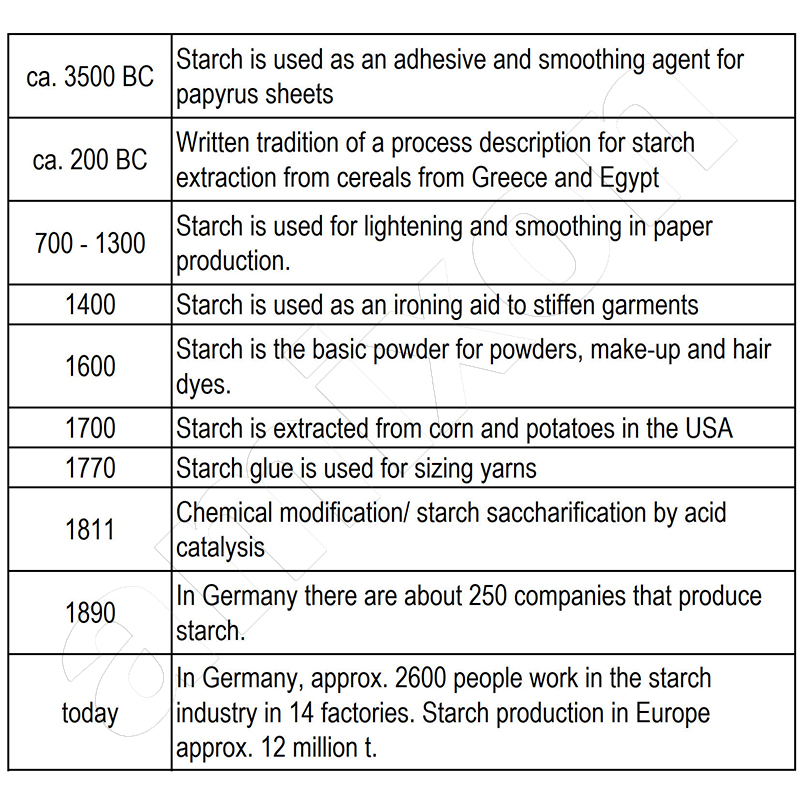

Starch has been used as an adhesive and filler for paints and medicine since ancient times.

The production of starch is simple but laborious. Ripe grain is soaked in water and crushed into a pulp with stones. The pulp is mixed with clean water. After a resting period, the floating components are poured off. The light-coloured sediment consists mainly of starch. This is dried in the sun. Starch powder was obtained from wheat in ancient times.

Later, our ancestors extracted potato starch in a similar way. In Europe, the starch industry developed as an agricultural sideline. People worked with the simplest equipment, which was only further developed into special process engineering machines in the course of industrialisation. This improved the degree of purity, yield and production costs.

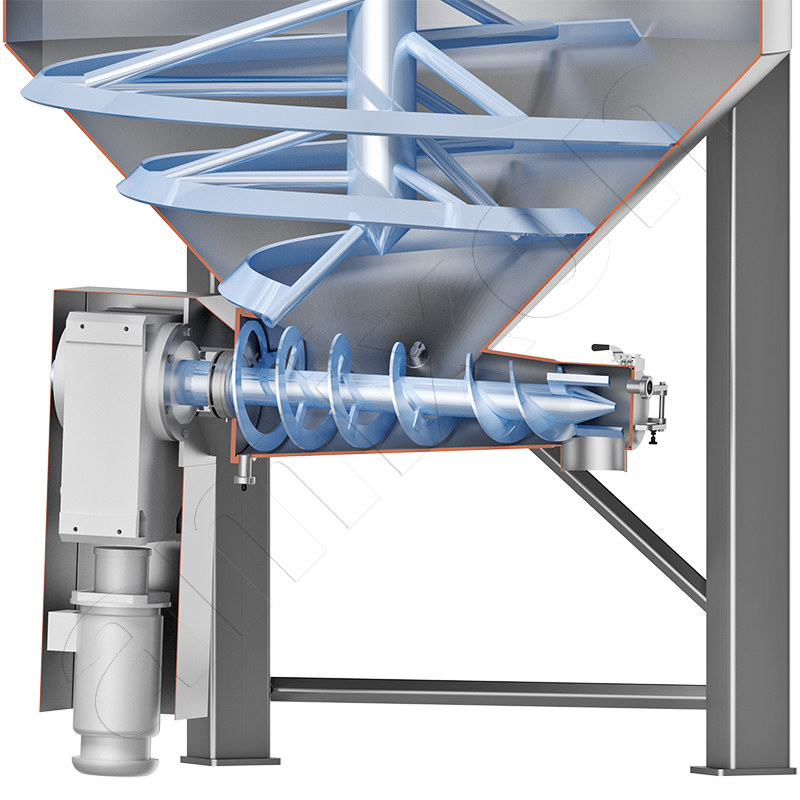

Gyraton® silo mixer for large quantities

Today, starch is a mass product. Customised starch derivatives are used in a wide variety of industries. In some cases, the resulting large batches have to be homogenised. amixon manufactures special silo mixers that can mix large powder masses very precisely. It does not matter whether the products are dry, moist or wet, flow well or poorly, ...

The production of starch is simple but laborious. Ripe grain is soaked in water and crushed into a pulp with stones. The pulp is mixed with clean water. After a resting period, the floating components are poured off. The light-coloured sediment consists mainly of starch. This is dried in the sun. Starch powder was obtained from wheat in ancient times.

Later, our ancestors extracted potato starch in a similar way. In Europe, the starch industry developed as an agricultural sideline. People worked with the simplest equipment, which was only further developed into special process engineering machines in the course of industrialisation. This improved the degree of purity, yield and production costs.

Gyraton® silo mixer for large quantities

Today, starch is a mass product. Customised starch derivatives are used in a wide variety of industries. In some cases, the resulting large batches have to be homogenised. amixon manufactures special silo mixers that can mix large powder masses very precisely. It does not matter whether the products are dry, moist or wet, flow well or poorly, ...

Three types of starch modification

Physical:

By heat treatment, grinding, pregelatinisation, roller drying, extrusion or agglomeration. This treatment is not subject to declaration for foodstuffs. Depending on the desired cold solubility, cost-effective roller drying or more expensive spray drying is used. The latter is usually combined with fluidised bed agglomeration if the starch is to have particularly good instant properties.

Chemical:

The starch is suspended in water in a stirred tank and, after adding small amounts of acid or alkali, is carefully heated without reaching gelatinisation temperature. After setting a certain pH value, a modifying reagent is added. After neutralisation, washing, filtration and drying, the starch has completely changed properties. If starch is chemically converted, degraded, dextrinised, esterified, etherified or oxidised, it is declared in foods as an additive with an E number or as modified starch.

If the crystalline structure of the starch granules is to be largely retained despite effective modification, the method of chemical cross-linking of the starch molecule groups with suitable hydroxyl groups such as ethylene or propylene oxide or dicarboxylic acids can be used. This reduces the solubility of the starch, increases the gelatinisation temperature and, depending on the degree of cross-linking, suppresses retrogradation.

Enzymatic:

Enzymes can organise and link molecular structures, form molecular chains and side chains. Enzymes can also split starch molecules: The enzymatic hydrolysis of starch is a highly efficient process for the saccharification of starch. This produces inexpensive sweeteners.

The enzyme catalytic hydrolysis of starch is slower than chemical cleavage. The conversion requires considerably less energy. The conversion takes place at a much lower temperature. Starch degradation can be stopped at any point.

Sometimes the process is ended with acid hydrolysis. This produces different types of starch syrup.

Effective enzymes are obtained, for example, from moulds, bacteria or the pancreas of cattle. This form of starch modification is not subject to declaration.

Physical:

By heat treatment, grinding, pregelatinisation, roller drying, extrusion or agglomeration. This treatment is not subject to declaration for foodstuffs. Depending on the desired cold solubility, cost-effective roller drying or more expensive spray drying is used. The latter is usually combined with fluidised bed agglomeration if the starch is to have particularly good instant properties.

Chemical:

The starch is suspended in water in a stirred tank and, after adding small amounts of acid or alkali, is carefully heated without reaching gelatinisation temperature. After setting a certain pH value, a modifying reagent is added. After neutralisation, washing, filtration and drying, the starch has completely changed properties. If starch is chemically converted, degraded, dextrinised, esterified, etherified or oxidised, it is declared in foods as an additive with an E number or as modified starch.

If the crystalline structure of the starch granules is to be largely retained despite effective modification, the method of chemical cross-linking of the starch molecule groups with suitable hydroxyl groups such as ethylene or propylene oxide or dicarboxylic acids can be used. This reduces the solubility of the starch, increases the gelatinisation temperature and, depending on the degree of cross-linking, suppresses retrogradation.

Enzymatic:

Enzymes can organise and link molecular structures, form molecular chains and side chains. Enzymes can also split starch molecules: The enzymatic hydrolysis of starch is a highly efficient process for the saccharification of starch. This produces inexpensive sweeteners.

The enzyme catalytic hydrolysis of starch is slower than chemical cleavage. The conversion requires considerably less energy. The conversion takes place at a much lower temperature. Starch degradation can be stopped at any point.

Sometimes the process is ended with acid hydrolysis. This produces different types of starch syrup.

Effective enzymes are obtained, for example, from moulds, bacteria or the pancreas of cattle. This form of starch modification is not subject to declaration.

amixon® fermenter/evaporator/vacuum mixer dryer

Enzymes help to fulfil market requirements The microorganisms in the enzymes can influence whether the starch product has hydrophilic or hydrophobic properties.

In the food sector, modified starches are used for the production of convenience products. They favour cooking, baking, roasting, shock freezing, defrosting, ... They accelerate flavour formation during the Maillard reaction.

If starch is to be used as a carrier for tablet masses, seasoning extracts, baking extracts or dessert products, it is important that the active ingredients and flavours are easily dispersible (whether dry or liquid). An amixon® mixer can also reliably achieve this.

Enzymes help to fulfil market requirements The microorganisms in the enzymes can influence whether the starch product has hydrophilic or hydrophobic properties.

In the food sector, modified starches are used for the production of convenience products. They favour cooking, baking, roasting, shock freezing, defrosting, ... They accelerate flavour formation during the Maillard reaction.

If starch is to be used as a carrier for tablet masses, seasoning extracts, baking extracts or dessert products, it is important that the active ingredients and flavours are easily dispersible (whether dry or liquid). An amixon® mixer can also reliably achieve this.

Significance and outlook

In Europe, most types of starch are interchangeable, especially when modified. Potato starch is slightly more expensive than cereal starch, as potato tubers are only available seasonally. The supply of wheat starch is currently increasing, as wheat gluten in particular is gaining in importance as a by-product. Wheat gluten / wheat protein is used in dried form in the bakery industry. Wheat gluten is an important raw material for meat substitute products. The extraction of starch from wheat is currently of double economic interest.

The total consumption of starch in Europe is approx. 12 million tonnes with an annual increase of approx. 2%. In the USA the increase is approx. 4%, in South America approx. 4.5% and in Asia as much as 7% per year. Around 10% of the starch produced worldwide is used in the chemical industry, around 30% in the paper and corrugated board industry, 30% in the food industry and around the same amount is modified or saccharified for the beverage and confectionery industry. It is expected that the demand for starch and starch derivatives will continue to increase in all industrial sectors.

In Europe, most types of starch are interchangeable, especially when modified. Potato starch is slightly more expensive than cereal starch, as potato tubers are only available seasonally. The supply of wheat starch is currently increasing, as wheat gluten in particular is gaining in importance as a by-product. Wheat gluten / wheat protein is used in dried form in the bakery industry. Wheat gluten is an important raw material for meat substitute products. The extraction of starch from wheat is currently of double economic interest.

The total consumption of starch in Europe is approx. 12 million tonnes with an annual increase of approx. 2%. In the USA the increase is approx. 4%, in South America approx. 4.5% and in Asia as much as 7% per year. Around 10% of the starch produced worldwide is used in the chemical industry, around 30% in the paper and corrugated board industry, 30% in the food industry and around the same amount is modified or saccharified for the beverage and confectionery industry. It is expected that the demand for starch and starch derivatives will continue to increase in all industrial sectors.

amixon®: Drying of starch derivatives under ultra-pure conditions

Drying begins with mechanical solid-liquid separation. Horizontally rotating peeler centrifuges or vertically rotating separators are used for this purpose.

The subsequent thermal drying must be suitable for continuous processes. As large quantities of powder are involved. These are, for example, roller dryers. However, this also includes convection dryers such as ring flow, spinning and grinding dryers. Both types of drying take place under atmospheric conditions. Roller dryers work at high temperatures. Convection dryers require large quantities of hot air, which must first be dried and cleaned.

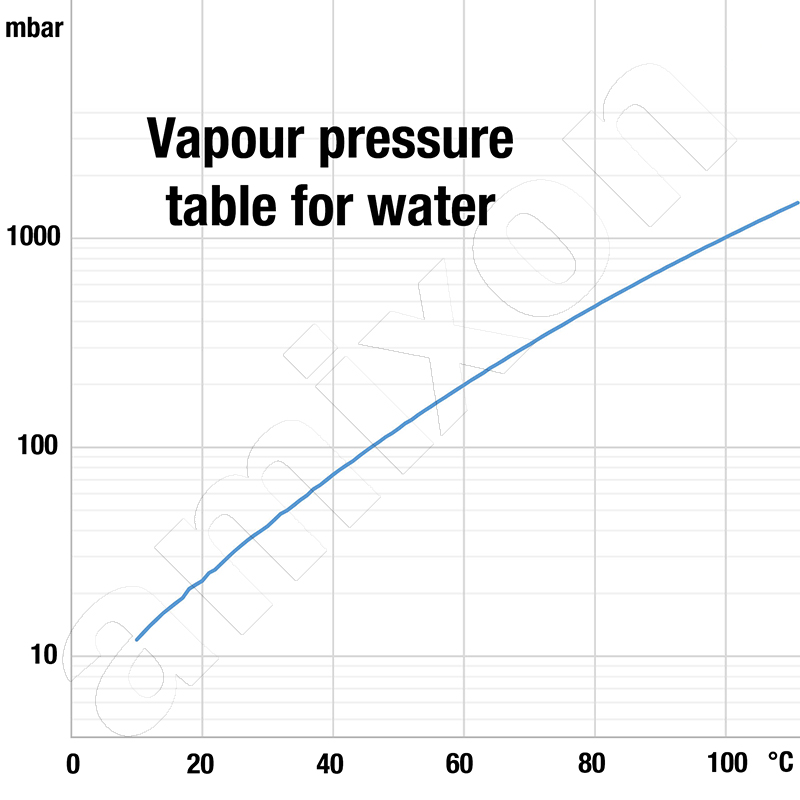

The amixon® vacuum mixer dryer offers an economical alternative for drying high-purity or temperature-sensitive starch derivatives. The applied vacuum accelerates drying at low product temperatures.

Vacuum mixing, drying, cooling, preparation

amixon® has more than 30 test machines. We invite you to test them. Bring your original products with you. 40 years of experience stand for efficiency and practical relevance.

Drying begins with mechanical solid-liquid separation. Horizontally rotating peeler centrifuges or vertically rotating separators are used for this purpose.

The subsequent thermal drying must be suitable for continuous processes. As large quantities of powder are involved. These are, for example, roller dryers. However, this also includes convection dryers such as ring flow, spinning and grinding dryers. Both types of drying take place under atmospheric conditions. Roller dryers work at high temperatures. Convection dryers require large quantities of hot air, which must first be dried and cleaned.

The amixon® vacuum mixer dryer offers an economical alternative for drying high-purity or temperature-sensitive starch derivatives. The applied vacuum accelerates drying at low product temperatures.

Vacuum mixing, drying, cooling, preparation

amixon® has more than 30 test machines. We invite you to test them. Bring your original products with you. 40 years of experience stand for efficiency and practical relevance.

Starch as a carrier substance for aromas and flavor formers

When using starch and starch derivatives as a carrier for liquid flavours, oleoresins, food colourings, baking extracts, oils and fats, one condition must be met: ‘Fast and uniform wetting with low energy input’. The production of aromas and flavourings, ready meals, soups, dips and sauces is often a multi-stage process. The cooler the overall mixture leaves the mixing plant, the better the subsequent filling, storage, quality retention and freshness consistency.

Specific coating effects are designed to enclose and protect the liquid ingredients. There is a major conflict of objectives here between the highest possible loading of liquid active ingredients on the one hand and the best possible flowability of the mixed powders on the other.

Here too, amixon® equipment provides excellent service worldwide. Test apparatus is available at all times.

When using starch and starch derivatives as a carrier for liquid flavours, oleoresins, food colourings, baking extracts, oils and fats, one condition must be met: ‘Fast and uniform wetting with low energy input’. The production of aromas and flavourings, ready meals, soups, dips and sauces is often a multi-stage process. The cooler the overall mixture leaves the mixing plant, the better the subsequent filling, storage, quality retention and freshness consistency.

Specific coating effects are designed to enclose and protect the liquid ingredients. There is a major conflict of objectives here between the highest possible loading of liquid active ingredients on the one hand and the best possible flowability of the mixed powders on the other.

Here too, amixon® equipment provides excellent service worldwide. Test apparatus is available at all times.

Starch has a wide range of applications.

Starch affects texture (sliminess) and turbidity, film formation, gelation and retrogradation. When starch is used in the food industry, it should be neutral in flavour and improve the end use for the consumer. Depending on the type of food, it should also positively support the mouthfeel.

- A cake spread should be cold-swelling and quick to prepare. The creamy flavour should be supported. When cutting the cake slices: Elasticity and shape retention.

- A spray-dried baby food should have good instant properties. The liquid mass should be lump-free and provide a good mouthfeel.

- The milk-based fruit dessert or yoghurt: Feels refreshingly cool in the mouth. It is not sticky or furry in the mouth. The filling machines work at high speed. Nevertheless, the liquid is easy to dose and does not drip.

- Barbecue sauce is easy to pour from the bottle. It remains thick on the hot barbecue food. In the mouth, it releases the spice flavours naturally.

- A breading or batter should coat the food evenly and adhere firmly. Regardless of whether the dish is eaten immediately or frozen, packaged and stored.

- An instant beverage powder should disperse quickly and without lumps in the liquid phase, even after prolonged storage.

- In a multi-stage fluidised bed process, volatile or oxidation-sensitive liquids can be microencapsulated with the aid of starch.

Retrogradation is generally undesirable.

Previously bound water is released again with a delay. Gels can liquefy. Such processes occur particularly with temperature changes, e.g. when cooling after cooking or when defrosting frozen food. Undesirable retrogradation can be minimised by using modified starches or by adding suitable emulsifiers.

Starch affects texture (sliminess) and turbidity, film formation, gelation and retrogradation. When starch is used in the food industry, it should be neutral in flavour and improve the end use for the consumer. Depending on the type of food, it should also positively support the mouthfeel.

- A cake spread should be cold-swelling and quick to prepare. The creamy flavour should be supported. When cutting the cake slices: Elasticity and shape retention.

- A spray-dried baby food should have good instant properties. The liquid mass should be lump-free and provide a good mouthfeel.

- The milk-based fruit dessert or yoghurt: Feels refreshingly cool in the mouth. It is not sticky or furry in the mouth. The filling machines work at high speed. Nevertheless, the liquid is easy to dose and does not drip.

- Barbecue sauce is easy to pour from the bottle. It remains thick on the hot barbecue food. In the mouth, it releases the spice flavours naturally.

- A breading or batter should coat the food evenly and adhere firmly. Regardless of whether the dish is eaten immediately or frozen, packaged and stored.

- An instant beverage powder should disperse quickly and without lumps in the liquid phase, even after prolonged storage.

- In a multi-stage fluidised bed process, volatile or oxidation-sensitive liquids can be microencapsulated with the aid of starch.

Retrogradation is generally undesirable.

Previously bound water is released again with a delay. Gels can liquefy. Such processes occur particularly with temperature changes, e.g. when cooling after cooking or when defrosting frozen food. Undesirable retrogradation can be minimised by using modified starches or by adding suitable emulsifiers.

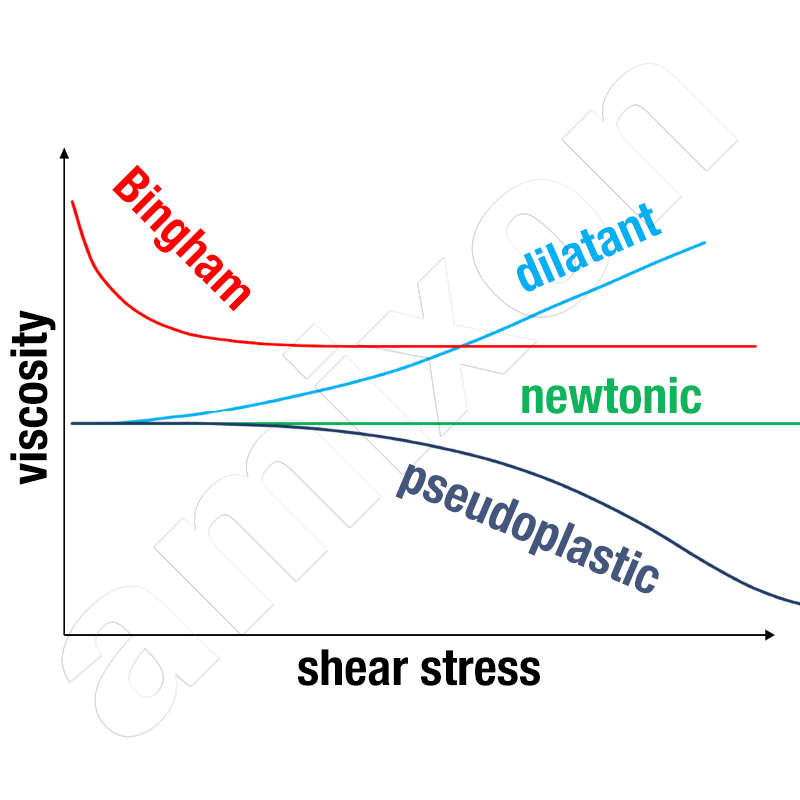

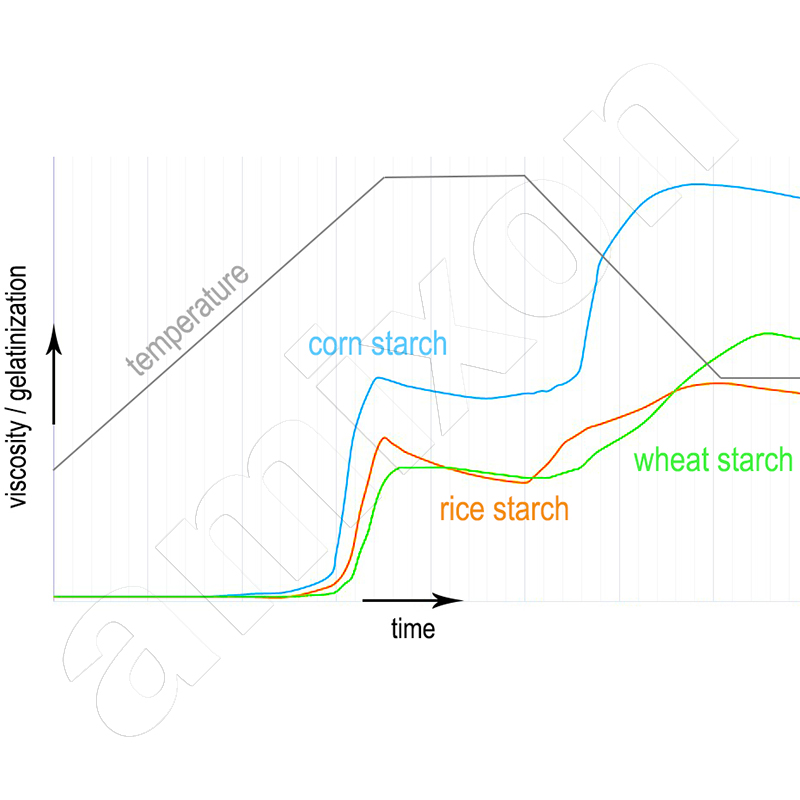

Gelatinisation and gel formation

If starch is heated in the form of an aqueous suspension, the starch granules are destroyed above a certain temperature. Swelling increases further and amylose is released from the grain. This process is known as gelatinisation. The viscosity increases, as does the clarity of the starch-water mixture and its electrical conductivity. It is a structurally viscous solution whose viscosity decreases the more the solution is stirred or sheared. On cooling, the solution becomes clearer, the glucose chains align in parallel and form new hydrogen bonds. Depending on the type of starch, a more or less stable gel is formed.

This structurally viscous behaviour is exactly the opposite of the initial state. A ‘starch in water suspension’ is dilatant. The higher the shear stress, the greater the increase in viscosity.

If starch is heated in the form of an aqueous suspension, the starch granules are destroyed above a certain temperature. Swelling increases further and amylose is released from the grain. This process is known as gelatinisation. The viscosity increases, as does the clarity of the starch-water mixture and its electrical conductivity. It is a structurally viscous solution whose viscosity decreases the more the solution is stirred or sheared. On cooling, the solution becomes clearer, the glucose chains align in parallel and form new hydrogen bonds. Depending on the type of starch, a more or less stable gel is formed.

This structurally viscous behaviour is exactly the opposite of the initial state. A ‘starch in water suspension’ is dilatant. The higher the shear stress, the greater the increase in viscosity.

Application examples for starch derivatives

Food and luxury foods:

- as an additive for instant foods

- as a filler for food supplement tablets

- as a viscosity regulator and clouding agent for instant beverages

- to increase creaminess in the production of desserts

- for conditioning sauces for frozen ready meals

- as a base for oleoresins in flavour and spice refinement

- to increase the water-binding capacity in sausage and meat processing

- as a binding agent in canteen kitchens and canteens

- as a filling agent for flavour enhancers

- as an additive to sugar to coat the particles with fat

- as an additive for baking agents and ready-to-bake flours

- as a conditioning agent for breadcrumbs

pharmaceuticals:

- as a lubricant for medical gloves

- as a filler to bring tablets to a manageable size

- as a coating and disintegrating agent for tablets

- as a base for medicinal powders and deodorants

- as a binding agent for medical active ingredients

- for stretching cosmetic blush

- as a release agent and lubricant for the trouble-free operation of tablet presses

- as a powdering agent to permanently separate sticky particles from each other

- as a viscosity regulator for creams, emulsions, ointments and even aerosols

metallurgy, mining, paper industry, chemicals, household goods:

- in the production of flocculants and defoamers for water treatment

- for the production of cooling lubricants for tunnelling and earth drilling

- for adjusting the flowability of concrete for concrete pumps

- for conditioning moulding sands in the foundry industry

- for smoothing cotton threads so that they can be woven without wear in textile production

- as an adhesive for stamps and corrugated cardboard

- for the production of wood glues

- as a smoothing and conditioning agent in paper production

Food and luxury foods:

- as an additive for instant foods

- as a filler for food supplement tablets

- as a viscosity regulator and clouding agent for instant beverages

- to increase creaminess in the production of desserts

- for conditioning sauces for frozen ready meals

- as a base for oleoresins in flavour and spice refinement

- to increase the water-binding capacity in sausage and meat processing

- as a binding agent in canteen kitchens and canteens

- as a filling agent for flavour enhancers

- as an additive to sugar to coat the particles with fat

- as an additive for baking agents and ready-to-bake flours

- as a conditioning agent for breadcrumbs

pharmaceuticals:

- as a lubricant for medical gloves

- as a filler to bring tablets to a manageable size

- as a coating and disintegrating agent for tablets

- as a base for medicinal powders and deodorants

- as a binding agent for medical active ingredients

- for stretching cosmetic blush

- as a release agent and lubricant for the trouble-free operation of tablet presses

- as a powdering agent to permanently separate sticky particles from each other

- as a viscosity regulator for creams, emulsions, ointments and even aerosols

metallurgy, mining, paper industry, chemicals, household goods:

- in the production of flocculants and defoamers for water treatment

- for the production of cooling lubricants for tunnelling and earth drilling

- for adjusting the flowability of concrete for concrete pumps

- for conditioning moulding sands in the foundry industry

- for smoothing cotton threads so that they can be woven without wear in textile production

- as an adhesive for stamps and corrugated cardboard

- for the production of wood glues

- as a smoothing and conditioning agent in paper production

Starch solubility

Starch is insoluble in cold water, but starch granules can swell easily and reversibly. This increases their volume by up to 28%. If water is removed from the starch, the swelling decreases.

Native starch can bind water or moist goods well. The binding capacity decreases with temperature fluctuations. Modified starch can solidify liquids over a longer period of time. It can stabilise gels.

The ‘Viscograph’ or ‘Rapid Visco Analyser’ provides a clear measuring technique for comparing the gelatinisation properties of different starch solutions. A starch-water suspension is heated and cooled with constant stirring. The stirring resistance is plotted against time.

Starch is insoluble in cold water, but starch granules can swell easily and reversibly. This increases their volume by up to 28%. If water is removed from the starch, the swelling decreases.

Native starch can bind water or moist goods well. The binding capacity decreases with temperature fluctuations. Modified starch can solidify liquids over a longer period of time. It can stabilise gels.

The ‘Viscograph’ or ‘Rapid Visco Analyser’ provides a clear measuring technique for comparing the gelatinisation properties of different starch solutions. A starch-water suspension is heated and cooled with constant stirring. The stirring resistance is plotted against time.

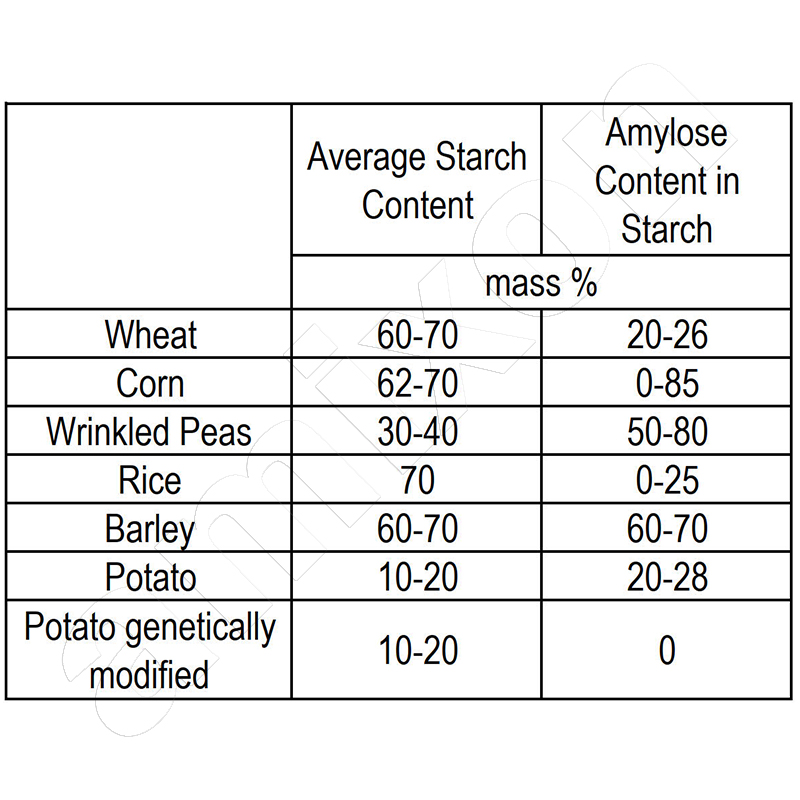

Amylose content and particle size

Depending on the type of starch, the starch grains are of different sizes. The diameter of starch particles can be over 100 µm in potatoes, 2 to 35 µm in wheat, 5 to 25 µm in corn, and only 0.5 to 3 µm in amaranth. Wheat starch has a bimodal distribution of starch grains. This is utilized to produce a high-purity A wheat starch (20 - 35 µm) on the one hand and a small-grain B wheat starch (2 - 10 µm) with higher impurities on the other.

Depending on the origin, starch usually has an amylose content of 14% to 27% and an amylopectin content of 73% to 86%. However, special plant varieties also provide starch with an amylopectin content of up to 99% or an amylose content of up to 85%.

Depending on the type of starch, the starch grains are of different sizes. The diameter of starch particles can be over 100 µm in potatoes, 2 to 35 µm in wheat, 5 to 25 µm in corn, and only 0.5 to 3 µm in amaranth. Wheat starch has a bimodal distribution of starch grains. This is utilized to produce a high-purity A wheat starch (20 - 35 µm) on the one hand and a small-grain B wheat starch (2 - 10 µm) with higher impurities on the other.

Depending on the origin, starch usually has an amylose content of 14% to 27% and an amylopectin content of 73% to 86%. However, special plant varieties also provide starch with an amylopectin content of up to 99% or an amylose content of up to 85%.

Starch particles with an amorphous or crystalline structure

Maltodextrin, e.g. for instant beverages, spice preparations, fruit preparations and ice cream, can be efficiently obtained in this way. The starch is suspended in water with alpha-amylase under slow stirring and is heated slowly. Defined stirring and residence times at different temperatures are observed to achieve the most complete enzymatic degradation possible. The suspension is then washed several times, centrifuged and thermally dried.

The integrity of native starch is easily demonstrated when the starch granules are viewed microscopically under polarized light. Due to the double refraction, the native starch grains appear iridescent with a dark cross, while the treated starch grains appear monochrome without a cross - obviously because their crystal structure is destroyed.

Maltodextrin, e.g. for instant beverages, spice preparations, fruit preparations and ice cream, can be efficiently obtained in this way. The starch is suspended in water with alpha-amylase under slow stirring and is heated slowly. Defined stirring and residence times at different temperatures are observed to achieve the most complete enzymatic degradation possible. The suspension is then washed several times, centrifuged and thermally dried.

The integrity of native starch is easily demonstrated when the starch granules are viewed microscopically under polarized light. Due to the double refraction, the native starch grains appear iridescent with a dark cross, while the treated starch grains appear monochrome without a cross - obviously because their crystal structure is destroyed.

Crops with their approximate starch and amylose contents

In Europe, the raw materials for starch production are potatoes, wheat and corn; outside Europe, starch is also obtained from the crops tapioca and rice. Today, the commercial product starch (C6H10O5)n may contain a maximum of 3% foreign substances. Internationally, the following rule has become established: The maximum permissible protein content in the dry matter of starch is limited. It is 0.58% for cereal starch and 0.13% for potato starch.

Low-protein wheat starch is obtained for dietary nutrients (e.g., celiac disease). The Codex alimentarius (international food regulations) defines starch as gluten-free if the protein content (gluten) is less than 20 mg/kg. Current analytical methods can detect residual protein levels below 5 mg/kg.

In Europe, the raw materials for starch production are potatoes, wheat and corn; outside Europe, starch is also obtained from the crops tapioca and rice. Today, the commercial product starch (C6H10O5)n may contain a maximum of 3% foreign substances. Internationally, the following rule has become established: The maximum permissible protein content in the dry matter of starch is limited. It is 0.58% for cereal starch and 0.13% for potato starch.

Low-protein wheat starch is obtained for dietary nutrients (e.g., celiac disease). The Codex alimentarius (international food regulations) defines starch as gluten-free if the protein content (gluten) is less than 20 mg/kg. Current analytical methods can detect residual protein levels below 5 mg/kg.

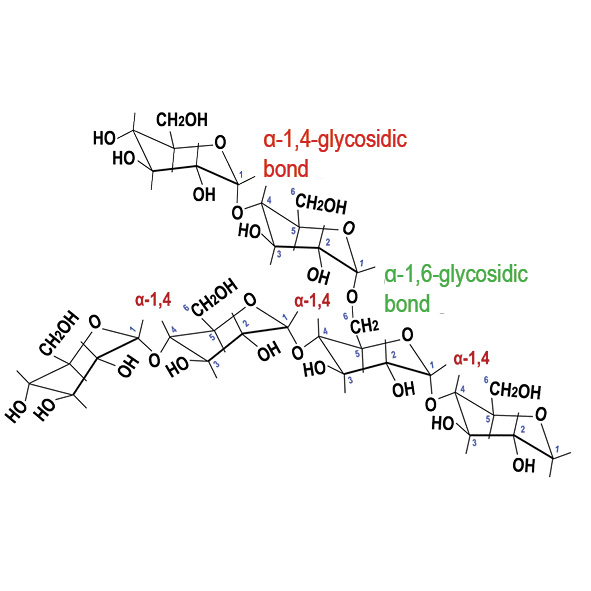

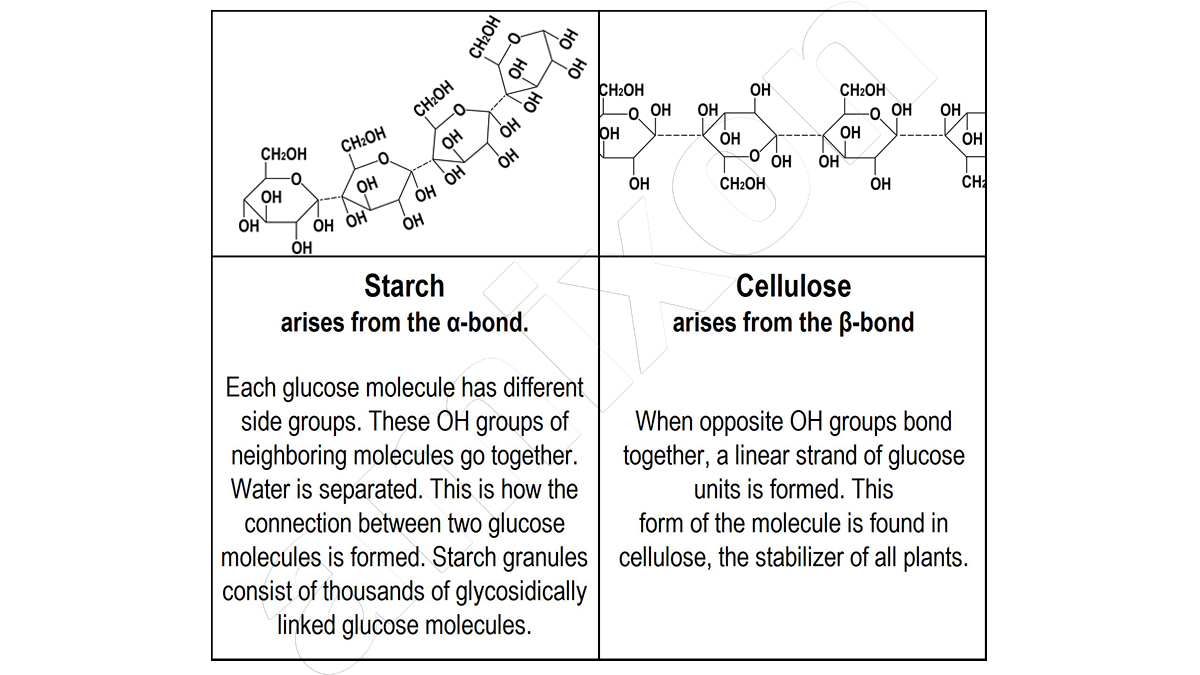

The chemical composition of cellulose and starch is very similar.

Starch, an energy carrier, is produced by photosynthesis and is stored in the tubers and seeds of all plants. Thousands of glucose molecules cross-link helically to form a starch molecule, which is incorporated into the starch granule.

Enzymes determine the composition and structure of starch granules. They can link glucose molecules into a long glycosidic strand. This structure is called amylose. If side chains are attached to the strand, it is called amylopectin.

The molecular similarity of starch and cellulose molecules is interesting. Starch is the energy store of plants, while cellulose forms the cellular skeleton of plants - with impressive strength and elasticity, just think of wood or 4 m high hemp stalks.

Starch, an energy carrier, is produced by photosynthesis and is stored in the tubers and seeds of all plants. Thousands of glucose molecules cross-link helically to form a starch molecule, which is incorporated into the starch granule.

Enzymes determine the composition and structure of starch granules. They can link glucose molecules into a long glycosidic strand. This structure is called amylose. If side chains are attached to the strand, it is called amylopectin.

The molecular similarity of starch and cellulose molecules is interesting. Starch is the energy store of plants, while cellulose forms the cellular skeleton of plants - with impressive strength and elasticity, just think of wood or 4 m high hemp stalks.

© Copyright by amixon GmbH