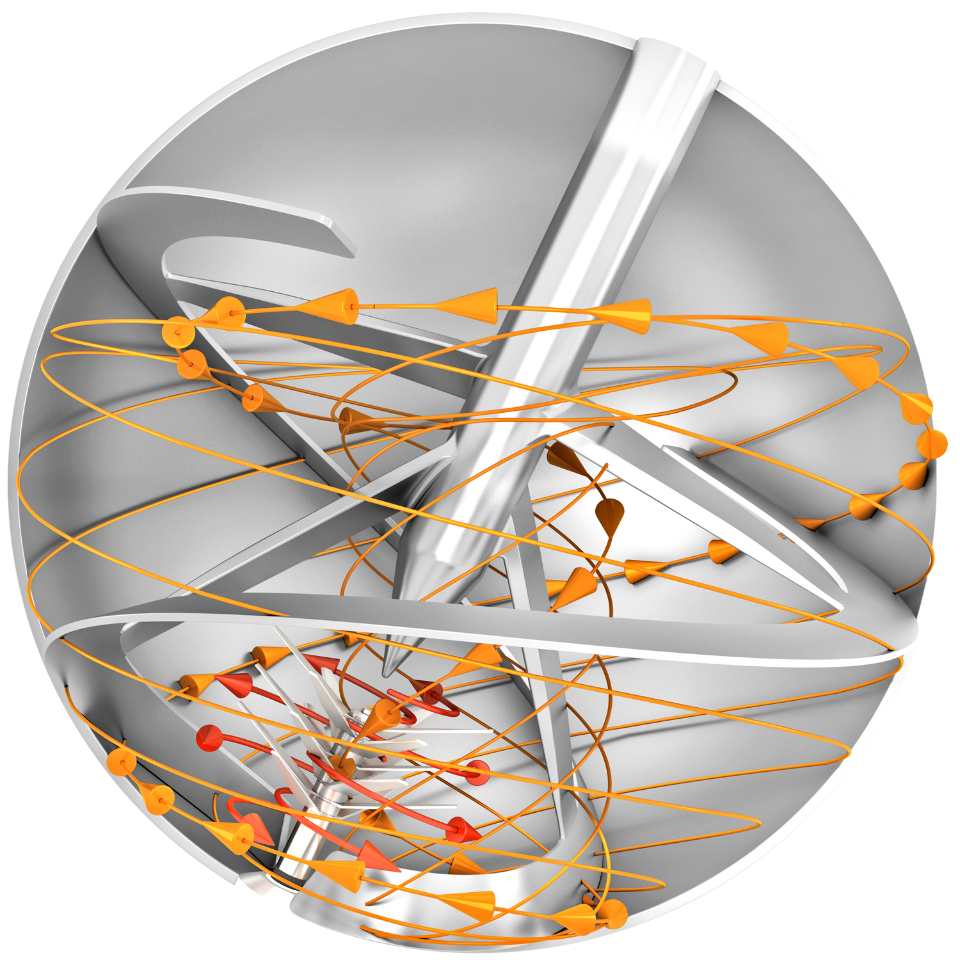

SpherHelics® Hollow spherical mixer Type SH

amixon® manufactures a wide range of vertical precision mixers. The spiral-shaped mixing tools rotate in conical, cylindrical or spherical mixing vessels. Detailed information on ball mixers can be found here.

Highest mixing quality in the shortest time

All amixon® mixers produce ideal mixing qualities. Even with component compositions of up to 1 : 100,000 and different filling degrees, an ideal distribution of the components is achieved after a very short mixing time. In practice, it is not possible to further improve this so-called ideal distribution. This exact mixing quality is also achieved by the amixon® hollow ball mixer.

Calculation of the turning frequency

The turning frequency describes how often the entire mixture is conveyed by the helical mixing tool. One turn corresponds to the complete volume of the mixing chamber that has been transported upwards once by the tool.

The conveying capacity of the mixing tool, also known as the displacement volume flow, can be calculated using the following formula:

IV = (π / 4) · (D² − d²) · Φ · S · n · ζ

IV: Displacement or conveying volume flow

D/d: Outer diameter/inner diameter of the helix

Φ: Filling degree (relative to the useful volume)

S: Pitch of the helix

n: Rotational frequency (revolutions per second)

ζ: Speed coefficient (tool-specific)

Mixing tests provide clarity

This formula can be used to design larger or smaller mixing machines. When extrapolating to large-volume ball mixers in particular, it is very helpful to carry out a mixing test in the technical centre beforehand. This allows the process-related properties of the product to be validated under realistic conditions.

Mixing quality alone is usually not enough

In addition to homogeneity, i.e. mixing quality, numerous other quality characteristics play a decisive role in the evaluation of a powder mixture. Depending on the design of the mixer, the following properties can be influenced:

- Grain size distribution (granulometry)

- Dust-free

- Flow behaviour and dosability.

- Stability against segregation.

- Appearance when mixing liquids with powder.

- Porosity

- Agglomeration or deagglomeration

- Compressibility/tabletability

- Dispersion behaviour in the end application

- Solubility behaviour in the end application

- Lump-free and free-flowing after storage

- Storage stability over longer periods

- Visual appearance after prolonged storage

The interaction of these properties is often decisive for the end customer. Therefore, mixing trials in the technical centre are an important step in selecting the most suitable mixing system.

AI-based optimisation

On request, amixon® carries out an AI-supported evaluation. This combines 40 years of documented amixon® expertise with the customer's specific process requirements. The result is a well-founded recommendation for the most suitable mixing system from the amixon® range.

- for the most suitable mixing system from the amixon® range

- for the most suitable mixer equipment

- for the best mixer operating mode

The batch volume V in a hollow sphere mixer can be easily calculated.

V(z) = π ⋅ z² ⋅ (3 ⋅ r – z)/3

V: Water volume

z: Fill level

r: Inner radius of the hollow sphere.

Since the mixing tool is ignored in the formula, it only provides an approximate value. The actual water volume is slightly lower.

Even if the mixing shaft is mounted at an angle, this type of mixer belongs to the vertical mixer category. This is the case with the amixon® spherical mixer. Its mixing effect is positively influenced by the angle of the mixer shaft.

amixon® has more than 40 years of experience in almost all industries where bulk materials are processed or refined. amixon® conducts ongoing research with scientists from various universities. Some of the results are so relevant that they have led to new products and further developments.

That is why we are always happy to invite our customers – both new and existing – to carry out mixing trials at the amixon® technical centre. This allows customer-specific challenges to be identified and amixon® to pass on a wealth of user know-how to the customer.

Many amixon® mixers are already over thirty years old. These too can be adapted to current customer requirements by means of a retrofit.

amixon® hollow sphere mixers can be manufactured in accordance with FDA regulations as sterile mixers and pressure-resistant double-jacketed reactors. They meet the requirements of EHEDG and 3-A Sanitary Standards.

What are the benefits for users of amixon® hollow sphere mixers?

- Ideal mixing quality and short mixing times

- Can be used for dry, moist and pasty goods as well as liquids

- amixon® hollow sphere mixers can be manufactured to FDA standards on request

- as sterile mixers and pressure-resistant double-jacketed reactors

- They meet the requirements of EHEDG and 3-A Sanitary Standards

- The SpherHelics® mixer can mix gently or aggressively to break up agglomerates

- Mixing times are very short

- Liquid additions are distributed quickly and precisely during mixing

- Excellent residual emptying on request with ComDisc® tools

- Simple and efficient cleaning, either dry or wet, fully automatic with WaterDragon® on request

- Drive power and energy consumption are low – particularly efficient

- amixon® has more than 30 modern test mixers. This ensures that you drive home with the best results!