Excursus: History of Instant Food

The history of instant food shows how technological advances and societal needs came together to develop convenient and versatile foods. As early as the 19th century, Justus von Liebig's meat extract made it possible to prepare meals quickly, while the Maggi cube provided simple and long-lasting flavor enhancers at the beginning of the 20th century. During the war, long-life food was developed for soldiers, and after the Second World War, Momofuku Andō's instant noodles revolutionized food culture.

The development of instant food has numerous advantages: it allows meals to be prepared quickly and easily, saves time and offers convenience, especially in stressful everyday situations. Instant food is durable and practical for storage and emergency supplies. The innovative power of this industry has led to a wide variety of products that also offer nutritionally valuable options. Instant food has also revolutionized the foodservice industry by ensuring consistent quality and efficiency.

If you would like to find out more about the preparation of instant food in amixon® precision mixers, you can find more information here:

Precision mixers for instant food

FAQ: The gentle powder preparation of instant ready meals

The ability to protect food from decay is a high cultural achievement.

Even more than 10,000 years ago, storing food by protecting meat or excess crops from spoiling was essential for survival. What we now call packaging was also a top priority back then.

Pits in the ground, leaves and animal skins were places of storage. Using clay jugs and woven baskets, our ancestors were able to meet further requirements: they were able to do trade with food, they were able to take stocks of food with them on journeys, during military conflicts and in times of crisis. They thus developed many ways of preserving and transporting food.

Recent history

At the start of the first industrial revolution, in 1852 the German chemist, Justus von Liebig, presented a dried meat extract, which seemed particularly advisable to him for supplying broad sectors of the population with food. His efforts to produce meat extracts on an industrial scale failed, however, due to cost reasons.

At the start of the 20th century, the Maggi cube appeared on the market as a plant-based instant food. Due to the cheaper raw materials, the Maggi cube prevailed against the dried meat extract. To this day, the stock cube is a blockbuster and the epitome of ready-to-eat instant foods.

Times of wars and crises often act as catalysts for ground-breaking innovations. When the United States government decided to enter the world war in 1941, it evaluated Europe as a potential hunger region. In order to supply the dispatched soldiers as best as possible nonetheless, high-calorie, non-perishable instant foods were developed. The rations consisted of three differently composed standard meals with a minimized proportion of water. These included stock cubes, dried fruits, chocolate, tinned meat, coffee and processed cheese. After adding hot water, the soldiers had nutritional meals with which their calorie and mineral intake was able to be covered over longer periods. In 1948, the Soviet military administration in Germany blocked the traffic of people and goods from and to West Berlin. The imminent lack of food in West Berlin would have been life-threatening if the allies had not set up an airlift. The limited air freight capacities had to be reserved for the most essential items, and only food without water content was supposed to be transported. As a result, industrial production facilities for dried foods were set up in the south of the United Kingdom with the help of the USA.

In Japan too, there were efforts to manufacture instant food after the end of the war. Momofuku Andō developed an instant noodle dish by cooking noodles and drying them as a porous block. Packaged in a cup with seasoning oil and flavors, all that was needed was to add hot water. He thus created the nucleus of what is now Nissin Foods, a Japanese manufacturer of countless instant meals. In 2020 one of their instant foods called space ramen was selected for manned space travel.

Erbswurst

Erbswurst (pease-flour sausage) was one of the oldest industrially produced instant meals. It is not a sausage in the proper sense, but instead portion tablets that are packed in a sausage-shaped paper roll coated with aluminium. These can be quickly made into a creamy pea soup by mashing the portion pieces, dissolving them in cold water and cooking for a few minutes. Erbswurst was developed in 1867 by the cook and canner, Johann Heinrich Grüneberg from Berlin. He soon sold his invention for 35,000 Vereinstaler to the Prussian army, which distributed it from 1870 onwards in the Franco-Prussian War – firstly as an “iron ration“– to its soldiers. Previous to that were trials by the Prussian War Ministry, where soldiers were fed solely on erbswurst and army bread for six weeks while doing their normal duties.

Functional Food

Back in those days, basic provisions with nutritional energy was a priority; although the taste was important, it was secondary. Nobody would buy the substitute food developed in an emergency back then these days because the food industry has improved the taste of instant food tremendously. Today we have an overwhelming array of instant meals based on dry ingredients. Instant specialties from a range of continents are even able to convince culinary spoiled consumers.

The term functional food was coined in Japan in 1985. By this it is meant that food increases well-being, is particularly beneficial to health and even helps to prevent illnesses. Although promotional promises to cure are not currently allowed in the EU, the term functional food is used in B2C circles. Supplementary additives are, for example, vitamins used as antioxidants, fiber, mineral nutrients, probiotics, prebiotics, unsaturated fatty acids, herb extracts from ginseng, aloe vera, ginko, isomaltose, .... Many providers have turned “functional food” into their business model and, with their instant meals, take on dietary aspects such as: natural metabolic stimulation, beauty from the inside, weight reduction, basic nutrition against hyperacidity, cellular purification and detoxification, vitalizing cell regeneration, wholesome food without sugar, inner balance and restful sleep, increased physical performance, stress resistance or fat burning.

“We are what we eat”. The philosopher and anthropologist, Ludwig Feuerbach, said that back in the 1830s.

Advantages and development of system catering

Much of what consumers appreciate and enjoy has also penetrated system catering. Commercial kitchens make use of all the benefits that make instant food attractive, but they do it in a clever way, because the instant specialties are reserved by the industry for professional cooks. What is more, they are cleverly combined with fresh or deep-frozen fruits. Even professional tasters confirm exquisite quality standards. Here too, the user benefits of instant goods dominate: Highly concentrated catering products reduce preparation times as well as personnel costs in the kitchen. Because powdered instant food components take up little storage space and are easily manageable, they give the cook a wide variety with an extremely short reaction time. The “success guarantee” largely applies here too. Instant food is purchased and procured to keep in stock, disconnected from day-to-day events.

Commercial kitchen of the Charité around 1900 - Bildquelle: https://commons.wikimedia.org/wiki/File:Charit%C3%A9,_Dampfkochk%C3%BCche.jpg

Fabrication

In order to meet the various requirements of end consumers and the catering sector, “basic instants” are made from a wide variety of dried, moist and liquid basic materials in industrial-style powder mixing plants. The number of individual components used is immense and reflects the vast array of spices, flavors, stabilizers, enzymes as well as additives, liquid extracts, oils and essences.

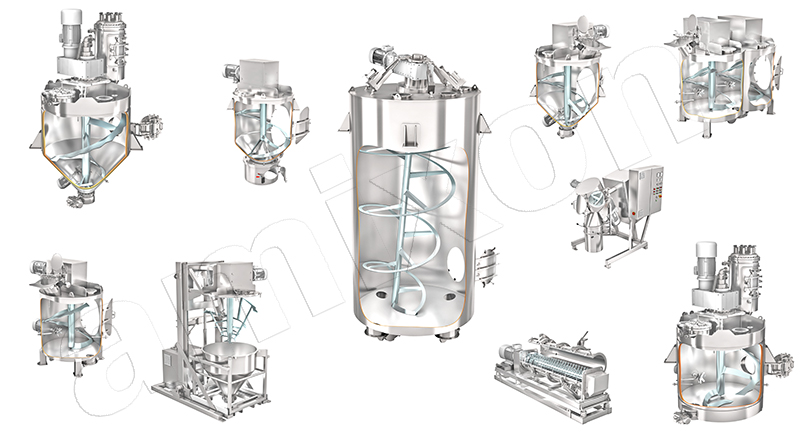

With only one exception, the amixon® manufacturing program features only vertically mounted helical mixing tools. This makes us the quality leader worldwide.

Our name is a global synonym for vertically designed precision mixers. The mixers are used across all industries for all types of dry, wet and suspended solids. Our manufacturing program is based on more than 30 proprietary patents (since the company was founded in 1983). All components of the mixers are exclusively manufactured in Germany. Motors and gearboxes are purchased from suppliers in Germany.

amixon® conical mixers either have a permanently installed mixing room (type AM) or they are manufactured as container mixers (type COM).

Both mixers provide ideal mixing qualities for all types of dry, moist or suspended solids (powder). Container mixers are popular when a lot of flexibility is required. The processes: component dosing, mixing and filling take place separately from each other. The stationary conical mixer type AM is a completely closed system (gas and water tight, pressure and vacuum tight). The chopper is in a low position. It is fully effective even at low filling levels.

Learn more about the preparation of instant food in amixon® mixers here.

[1] Source: https://de.wikipedia.org/wiki/Erbswurst

© Copyright by amixon GmbH