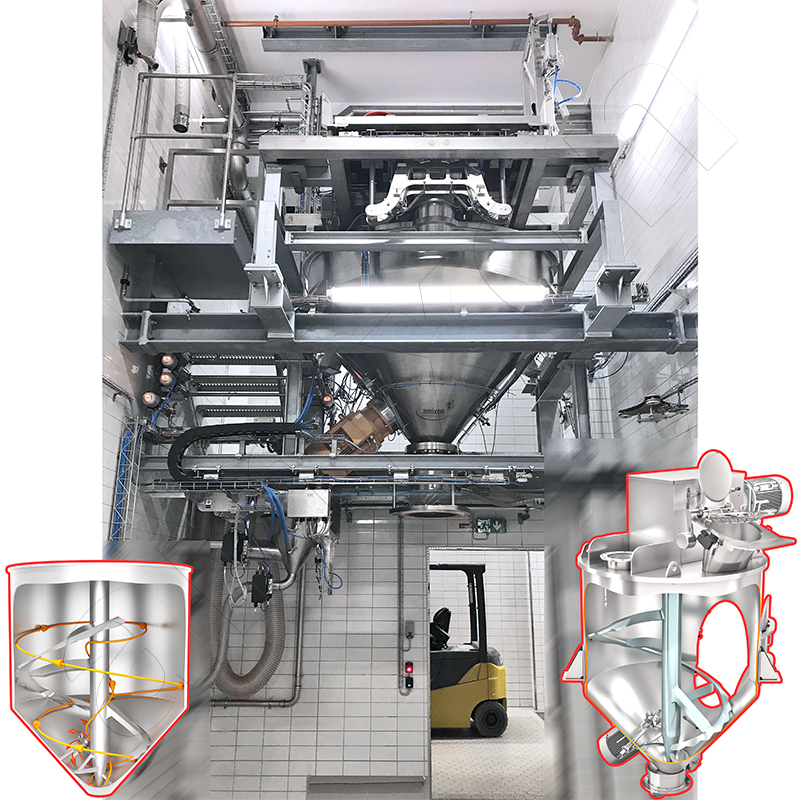

amixon® twin-shaft mixer HM 4000 with 4 m³ usable volume. Designed for the particularly gentle preparation of powdered instant ready meals.

The ingredients of an instant meal are very different. Some are fine as dust, others agglomerated or even lumpy. Some are greasy, others extremely hygroscopic and still others hydrophobic. Some are easy to dose, others are available as a semi-solid mass. Freeze-dried meat preparations, dried vegetables, pre-processed saturated side dishes such as rice, potato flakes or pasta are more or less lumpy, with particle sizes of 3 cm and more. There are also a wide variety of liquid flavours.

A mixer for instant food has to solve complex tasks in a field of conflicting challenges. We have taken up and answered typical, recurring questions from our customers below.

How can heterogeneous mixtures be protected against segregation?

Depending on the type of instant dish, 40 or more individual components may be involved in the recipe. Most of the components are bulk materials (lumpy or powdery). Other components are liquid (thin or highly viscous). You can add all components to the mixer at the same time and then start the mixing process. When using an amixon® mixer, a homogeneous end product is always obtained. However, the instant ready meal has much better properties if you proceed step by step:

First, the fine and robust powders are added to the mixer and mixed intensively. After 90 to 120 seconds, the liquid is added. After a short time, the powder is completely wetted. In this way, the dusty powders are effectively bound.

The mixing tools then stop and further powder components are added to the mixer. The mixing process continues. Fine agglomerates are formed. The mixing process is stopped again and coarse powders are added. The mixing process is restarted and dried vegetables, seasoning, onion rings etc. are added last.

This procedure guarantees a good-tasting end product that looks wonderfully natural. Agglomerates and liquid substances form a matrix in which the coarse ingredients are embedded .

amixon® Twin-Shaft mixers mix particularly gently, as they only require a third of the mixing time. The mixing tools have a peripheral speed of 1 m/s to 2 m/s.

Depending on the type of instant dish, 40 or more individual components may be involved in the recipe. Most of the components are bulk materials (lumpy or powdery). Other components are liquid (thin or highly viscous). You can add all components to the mixer at the same time and then start the mixing process. When using an amixon® mixer, a homogeneous end product is always obtained. However, the instant ready meal has much better properties if you proceed step by step:

First, the fine and robust powders are added to the mixer and mixed intensively. After 90 to 120 seconds, the liquid is added. After a short time, the powder is completely wetted. In this way, the dusty powders are effectively bound.

The mixing tools then stop and further powder components are added to the mixer. The mixing process continues. Fine agglomerates are formed. The mixing process is stopped again and coarse powders are added. The mixing process is restarted and dried vegetables, seasoning, onion rings etc. are added last.

This procedure guarantees a good-tasting end product that looks wonderfully natural. Agglomerates and liquid substances form a matrix in which the coarse ingredients are embedded .

amixon® Twin-Shaft mixers mix particularly gently, as they only require a third of the mixing time. The mixing tools have a peripheral speed of 1 m/s to 2 m/s.

Which type of liquid addition is most suitable?

Some liquids are low viscosity, others are high viscosity and should be heated beforehand. Still others are structurally viscous or even dilatant. Sometimes it is advantageous to prepare several liquids in a "premix".

Some oils are solidified by whipping with inert gas at high speed and cooling (shortening). In this way, the powders remain free-flowing despite the high oil content.

The respective rheological properties of the liquids determine how the liquid is added to the powder.

- Gravimetric addition

- Single-fluid nozzle

- Multi-substance nozzle

- Low or high pressure pump

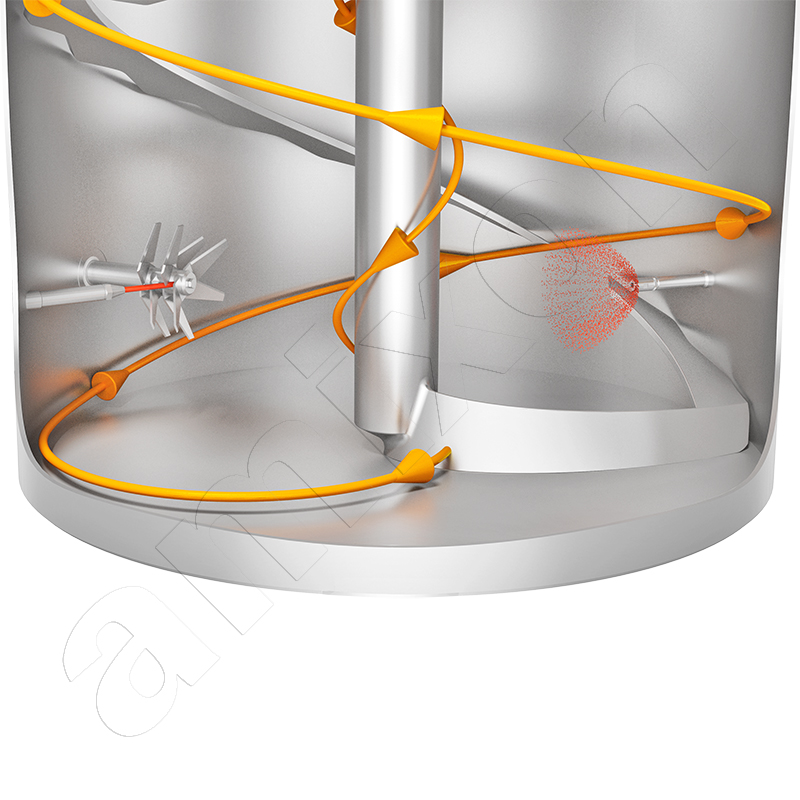

Cylindrical amixon® mixer: Left: Single-fluid nozzle targets the vortex zone of the cutting rotor; intensive disagglomeration. Right: Multi-substance nozzle creates a fluidisation zone and atomises the liquid into micro-fine droplets; very gentle.

Some liquids are low viscosity, others are high viscosity and should be heated beforehand. Still others are structurally viscous or even dilatant. Sometimes it is advantageous to prepare several liquids in a "premix".

Some oils are solidified by whipping with inert gas at high speed and cooling (shortening). In this way, the powders remain free-flowing despite the high oil content.

The respective rheological properties of the liquids determine how the liquid is added to the powder.

- Gravimetric addition

- Single-fluid nozzle

- Multi-substance nozzle

- Low or high pressure pump

Cylindrical amixon® mixer: Left: Single-fluid nozzle targets the vortex zone of the cutting rotor; intensive disagglomeration. Right: Multi-substance nozzle creates a fluidisation zone and atomises the liquid into micro-fine droplets; very gentle.

Does the multi-stage mixing process deliver the best results?

Yes, due to the heterogeneity of the components and their different robustness/fragility. Sometimes separately produced powder premixes are also added in a stop-and-go process. Finally, the chunky, sensitive components are added. These are, for example, freeze-dried meat preparations, dried vegetables, pre-treated croutons, rice, potatoes or pasta.

The final mixing step often only takes 10 to 20 seconds. This mixing process is extremely gentle. Nevertheless, the product is optimally mixed. The fragile ingredients are not damaged.

One and the same amixon® mixer works in completely contrasting processes:

- aggressive deagglomeration with high energy input

- extremely gentle, gentle "homogenising" with minimal agitation

In this way, amixon® mixers achieve premium qualities that are unrivalled. At the end of the mixing process, the dead-space-free discharge valve is opened. The mixing tools now rotate extremely slowly and discharge the mix particularly gently. This happens without particle breakage and absolutely segregation-free down to the last residue. amixon® mixers discharge almost completely.

Yes, due to the heterogeneity of the components and their different robustness/fragility. Sometimes separately produced powder premixes are also added in a stop-and-go process. Finally, the chunky, sensitive components are added. These are, for example, freeze-dried meat preparations, dried vegetables, pre-treated croutons, rice, potatoes or pasta.

The final mixing step often only takes 10 to 20 seconds. This mixing process is extremely gentle. Nevertheless, the product is optimally mixed. The fragile ingredients are not damaged.

One and the same amixon® mixer works in completely contrasting processes:

- aggressive deagglomeration with high energy input

- extremely gentle, gentle "homogenising" with minimal agitation

In this way, amixon® mixers achieve premium qualities that are unrivalled. At the end of the mixing process, the dead-space-free discharge valve is opened. The mixing tools now rotate extremely slowly and discharge the mix particularly gently. This happens without particle breakage and absolutely segregation-free down to the last residue. amixon® mixers discharge almost completely.

Processing tests under real conditions

You can try out all this and much more at the amixon® test centre. Our experts will show you new mixing and processing methods. Bring your toughest challenges with you! We look forward to seeing you. The amixon mixing systems HM and KS are predestined for this.

The service life of mixers is often 30 years. The investment in a powder mixing system has a long-term effect. It amortises quickly,

- if the mixed products are better than before

- if labour costs are saved

- if the use of raw materials is optimised

- if cleaning is better/faster

- ....

You can try out all this and much more at the amixon® test centre. Our experts will show you new mixing and processing methods. Bring your toughest challenges with you! We look forward to seeing you. The amixon mixing systems HM and KS are predestined for this.

The service life of mixers is often 30 years. The investment in a powder mixing system has a long-term effect. It amortises quickly,

- if the mixed products are better than before

- if labour costs are saved

- if the use of raw materials is optimised

- if cleaning is better/faster

- ....

© Copyright by amixon GmbH