amixon® mixers for "seafood" instant products

Fishery products include all edible species and parts of marine and freshwater animals. It is irrelevant whether they live in the wild or are farmed. Fishery products are used to feed billions of consumers. Thanks to modern aquaculture techniques, seafood has become the most traded product in the world. Reliable conservation techniques and a global network of deep-freeze logistics ensure availability, freshness and quality. New product innovations are also constantly being created from sea plants.

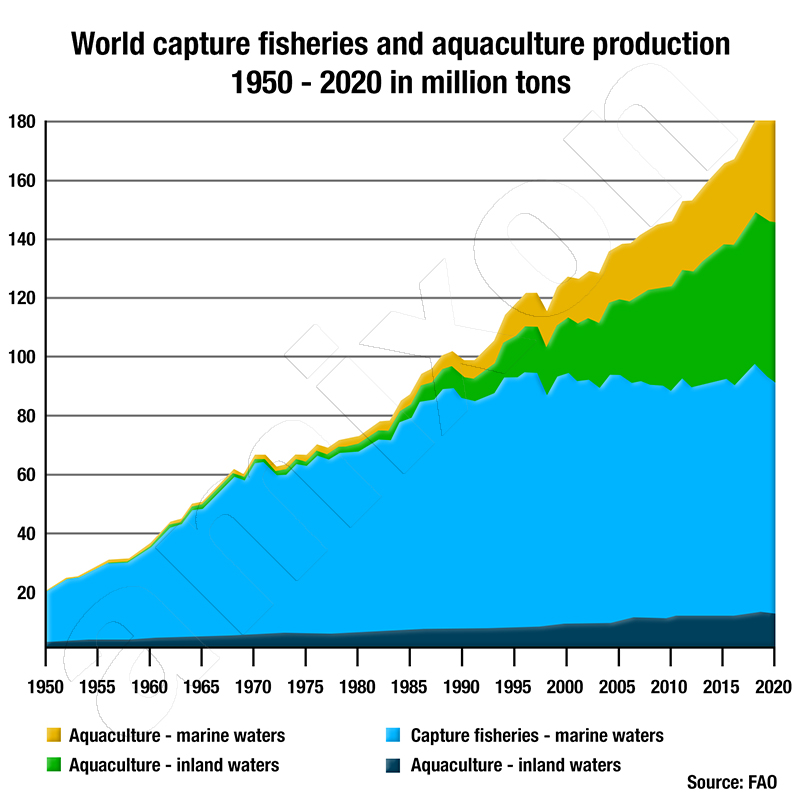

The United Nations has calculated that more than 170 million tons of fish and seafood are caught and farmed worldwide. Interestingly, only 22 million tons are consumed. Statistics show that global consumption of seafood has been twice as high as population growth over the last 40 years. In 2022, Asia accounted for 73% of global seafood sales.

Hygienic process engineering

amixon® has been supplying all areas of the food industry for over 40 years. We are highly specialized in powdery, dry, moist, wet, highly viscous, dusty or granulated products. amixon® equipment works continuously or discontinuously. Our expertise relates to:

- Tempering

- Sterilize

- Vaporize

- Preserving

- Sterilization

- Mixing

- React (also enzymatic)

- Ferment

- Vacuum drying

- Agglomerate

- Disagglomerate

- Instantize

- Freeze-drying

- ....

"Blue foods" is the collective term for foods that originate from marine and freshwater ecosystems.

The world population is expected to grow to 10 billion people by 2050. There is no question that marine and aquatic food resources are becoming increasingly important. More than 3,000 different aquatic foods are already being used, and the number is increasing. Compared to meat, seafood has a much higher specific nutrient content. Much less carbon dioxide is emitted during the production and processing of Blue Foods. Interestingly, small fish cause significantly lower specific CO2 emissions than large fish. The UN recommends increasing the production of seafood. In return, meat production should be reduced.

More than 800 million people worldwide earn their living in the "blue food" industry. In 2020, global aquaculture production will reach a record 122.6 million tons with a total value of 281.5 billion US dollars.

A good nutritional balance is not always synonymous with good taste.

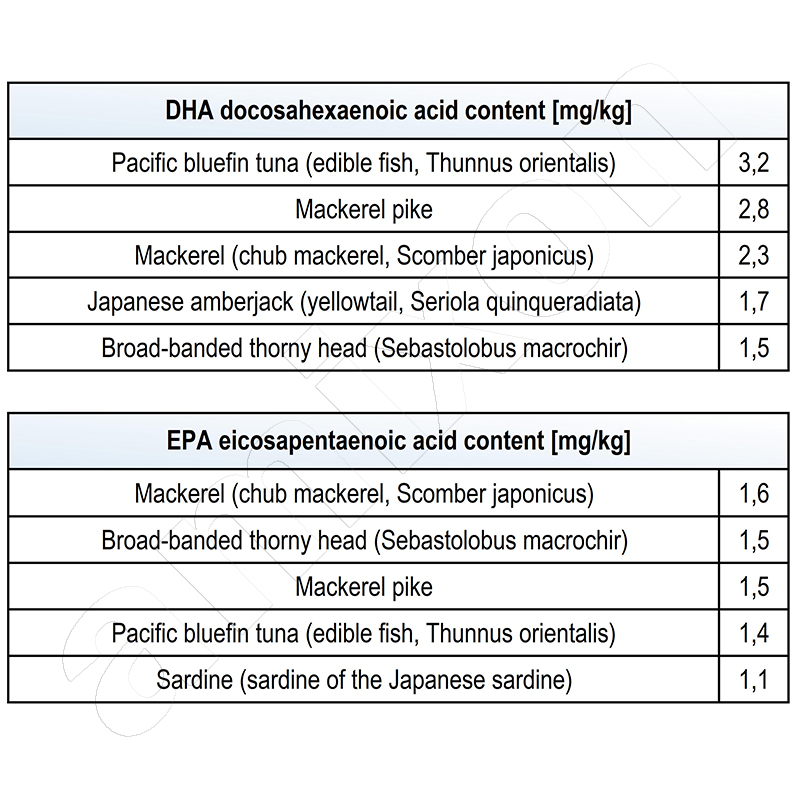

Seafood contains a relatively large amount of amino acids that cannot be produced by the human body. In addition, specific vitamin complexes, calcium, taurine, collagen and the omega-3 fatty acids docosahexaenoic acid (DHA) and eicosapentaenoic acid (EPA).

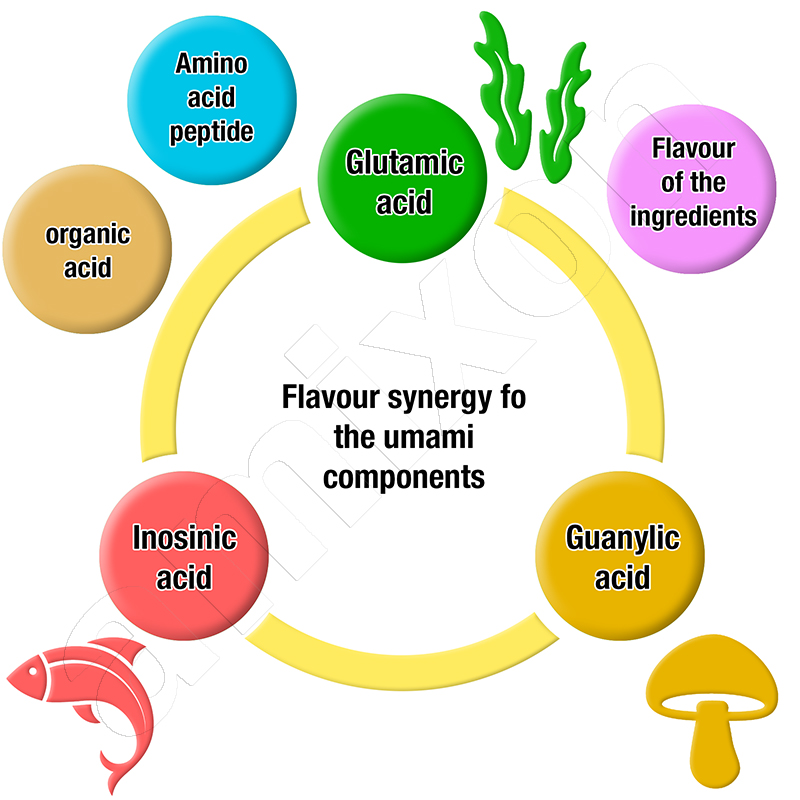

For a long time, people were convinced that the human sense of taste only recognizes the tastes sweet, sour, salty and bitter. Dr. Kikunae Ikeda from the University of Tokyo extracted glutamic acid from seaweed, inosinic acid from bonito flakes and guanylic acid from shiitake mushrooms. This is how he discovered the spicy aroma called umami in 1908.

Garden and field crops change their taste depending on the season. The situation is similar with many seafood products. Before fish spawn, they have stored glycogen, fats and amino acids in their bodies. Then they taste different than usual. In industrial processing, flavorings help to balance out seasonal fluctuations in taste.

The good taste of seafood is sometimes short-lived.

Seafood is more sensitive than meat and vegetables. It oxidizes very quickly due to the oxygen in the air, which leads to a rancid/fishy taste. Seafood must therefore be processed cool, fast and - if possible - inert. Proper processing affects all seafood derivatives, from fresh fish to instant fish soup, from dried fish to seaweed.

Marine algae can adapt very well to changing living conditions. They are undemanding and grow quickly. Marine algae are becoming increasingly important in the fight against global food shortages. The production of seaweed through aquaculture has increased significantly over the last two decades. Asia accounts for the largest share of global algae production (97.38%). In Asia, 99% of algae are artificially cultivated.

Typical algae are

- Seaweed / Kelp (Laminaria japonica),

- Wakame (Undaria pinnatifida),

- Ogonori (Gracilaria algae),

- Nori (Porphyra tenera),

- Kirin rhinoceros (Rhinoceros japonicus) and

- Nettai-Kirin rhinoceros (Kappaphycus alvarezii) is cultivated.

amixon® mixers/ blenders instantize shelf-stable seafood.

In practice, various methods are used to protect seafood from oxidation. Cyclodextrin or calcium hydroxide is added before drying.

Another method is to reduce the salt content of the algae before drying. Unpleasant flavors can be absorbed by adding wood flour and mussel powder.

amixon® mixers and sterile reactors are used for the instantization of seafood. They produce ideal mixed qualities, regardless of whether heterogeneous or homogeneous material compositions are involved. It is irrelevant whether the substances are moist, greasy or dry.

- amixon® mixers have a particularly hygienic design and are considered microbiologically controllable.

- amixon® blenders can be almost completely emptied and enable contamination-free mixing operation.

- amixon® mixers mix particularly gently. This preserves the granulometry of the raw materials during the mixing process.

- amixon® blenders can be operated with different filling levels. The mixing quality is always the same.

- amixon® mixers can be integrated into both an inline and an offline production line. They can also be operated both batch-wise and continuously.

- amixon® blenders and sterile reactors are capable of efficiently sterilizing food and animal feed.

Seaweed

Seaweed/sea grass is frugal and rich in nutrients. It requires no fertilizer, binds carbon dioxide and helps to clean the coastal waters. Algae farmers benefit from the seaweeds Kappaphycus and Wakame.

Wakame seaweed is a seasonal product that is harvested from January to April. In many Asian countries, however, wakame algae are part of the daily diet. The algae are preserved by deep-freezing, freeze-drying, inert convection drying or fermentation. This involves two challenges:

- The taste must remain fresh. - Algae can quickly take on a bland taste. -

- The shape and color of the algae must be preserved as much as possible.

It is easy to tell whether the drying process of an algae is working well. When dried wakame is added to the soup, it returns to its original size within seconds and turns bright green.

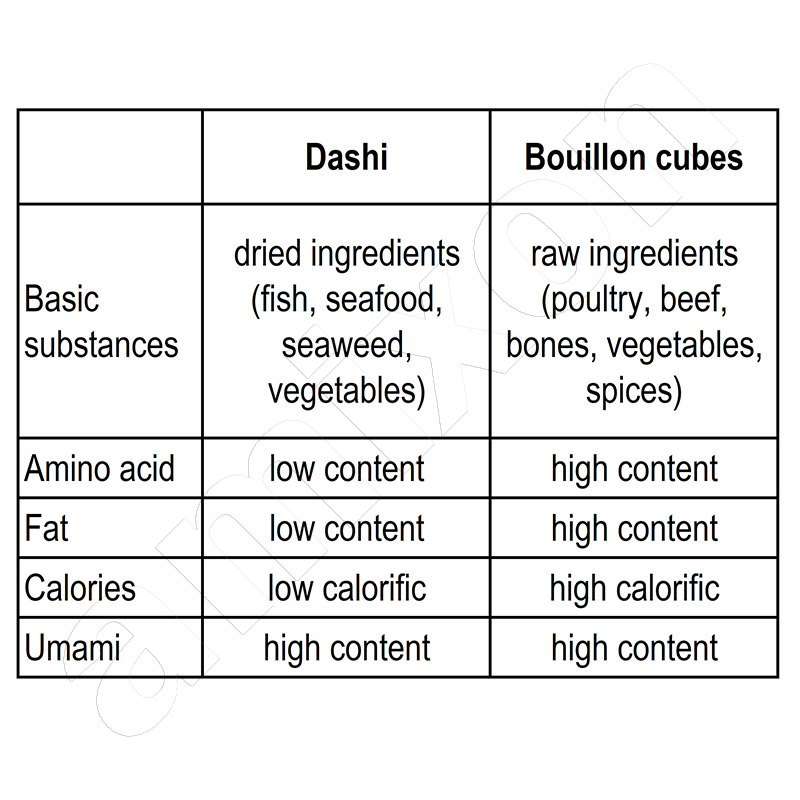

Dashi, the dry soup from the bag

Dashi is a mixture of small fish, seaweed, Japanese sardines, bonito, meji, souda bonito, mackerel, kombu, herbs and shiitake mushrooms. These were previously cleaned, dried, crushed and refined with flavors in the amixon® mixer / blender. This mixing process produces virtually no abrasion/dust.

Dashi is filled into filter bags. Each bag is enough for one cup of fish soup. Unlike the classic soup cube, dashi is not eaten. Like a tea bag, dashi is removed from the cup after a certain time and disposed of.

Excursus: amixon® mixers/ blenders for the preparation of feed for aquaculture production

The production of seafood through aquaculture is efficient. It makes ecological and economic sense if it is operated correctly. In the past, it was common to feed by-catches, crabs, mussels, anchovies, sprats and mackerel. Today, only leftovers from fish processing are fed to aquaculture facilities. The proportion resulting from seafood is less than 10 %. The leftovers are mixed with cereals, oilseeds and pulses and processed into pellets that can also be fed below the water level.

Fattening and rearing success depends on the quality of the feed. The food must be microbiologically flawless and be easily recognized and eaten by the fish. It must be the right color and size. It must float or float on the water without dissolving.

amixon® mixers and sterile reactors provide valuable services here. They can sterilize animal processing residues and dry them under vacuum. This is done at a low temperature. This preserves fish oils. amixon® mixers and blenders can disperse even the smallest powder additives microfine into the batch. This allows the mixing goods to be compacted effectively. Prills, granules, flakes, flakes or pellets have defined sizes that are tailored to the respective fish species. amixon® mixers ensure high-quality mixed feed (mixed qualities) for the efficient rearing of underwater enclosures.

Western cuisine also benefits from the nutritional know-how from Asia.

Algae grow under water and do not require cultivation or irrigation. Photosynthesis converts sunlight and the carbon dioxide present in the water into biological substance. Algae grow quickly. Their dry matter contains five times more protein than soy.

Even though Western civil society has consumed comparatively few algae products to date, there are interesting start-ups that see a large future market. In the USA, for example, the company Umaro has developed vegetarian ham for burgers. Other companies such as AKUA in the USA or The Dutch Weed Burger in the Netherlands are already established with their products.

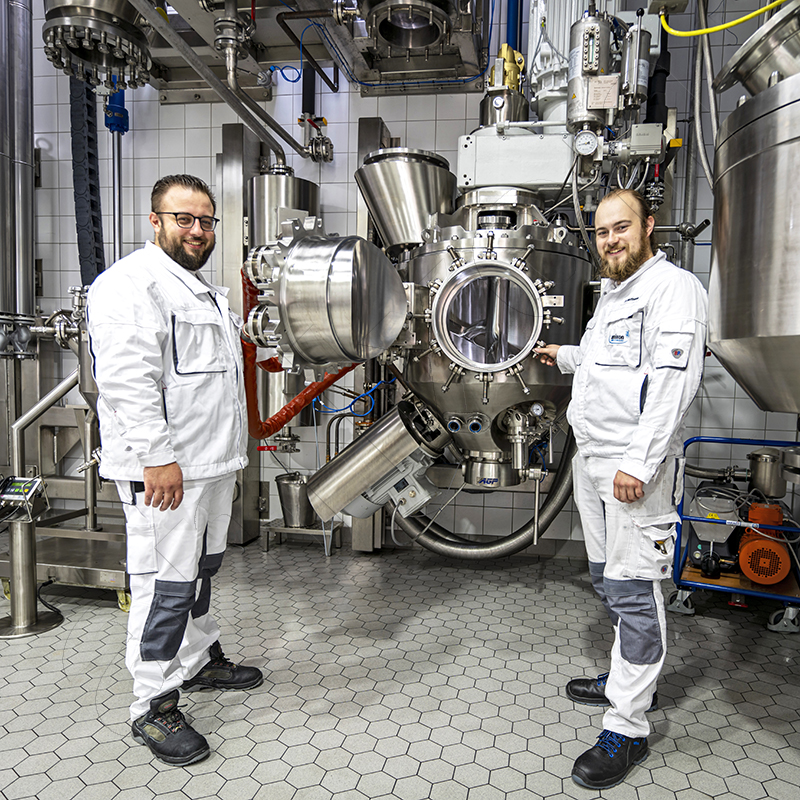

The new amixon® technical center offers excellent testing possibilities.

A test day in the amixon® test center can greatly enrich your product development. More than 30 different test machines (mixers/ blenders, sythesesreactors, vacuum mixers / blenders/ dryers) are at your disposal.

© Copyright by amixon GmbH