Hygienic design and HACCP for mixing powdery or moist food and pharmaceutical products

Despite the utmost care, food, pharmaceuticals and cosmetics can become unusable before the best-before date. In the case of powdered mixed products, this applies, for example, to spices, flavour extracts, baking agents, stabilisers, nutrient substrates for fungal cultures, ferments for starch processing and milk processing. Food supplements, dietary foods, infant formula, vitamins and trace elements. But also cheese, meat substitutes, antibiotics and active pharmaceutical ingredients.

amixon® has realised many pioneering developments to improve the hygiene standards of powder mixers. Some of these are described below.

The HACCP principles are a preventive set of rules that help to recognise, evaluate and avoid sources of error and ensure food safety. The abbreviation stands for "Hazard Analysis Critical Control Point". In the EU, the obligation to apply HACCP has been laid down in Regulation (EC) No 852/2004 on the hygiene of foodstuffs since 2006.

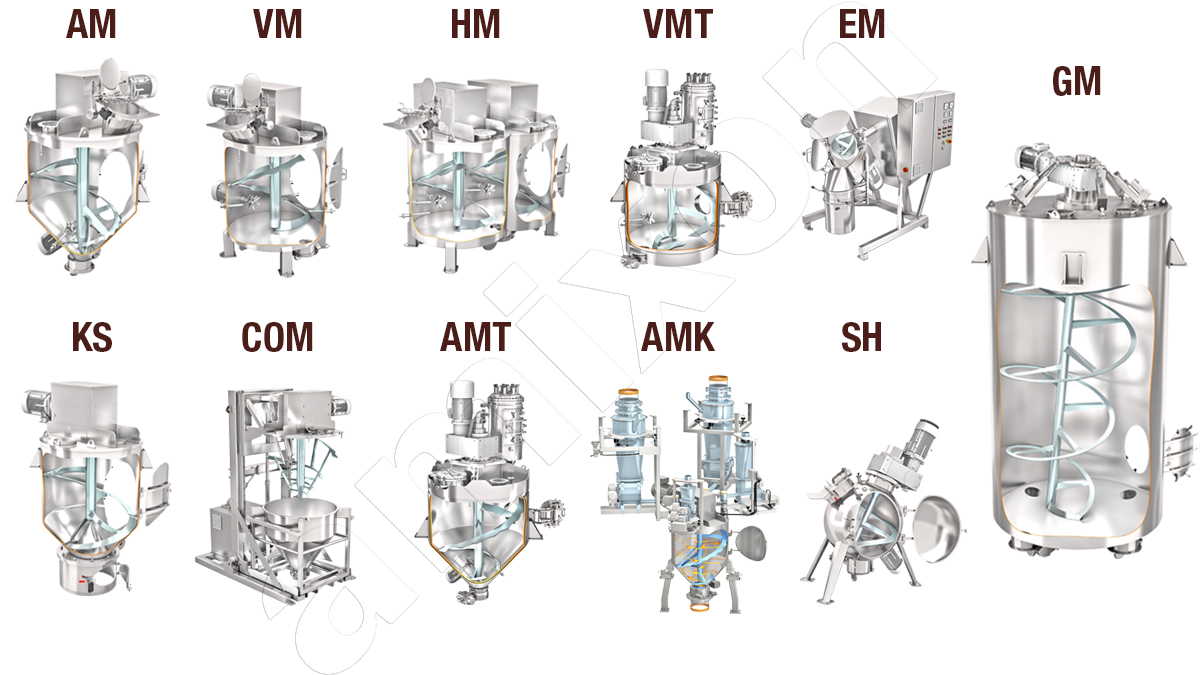

amixon® is the global quality leader for vertical powder mixers. amixon® mixers have vertical or inclined mixing shafts. They are only supported at the top. There is only one shaft seal, which is located at the top. The design of the shaft seal is adapted to hygienic conditions. The mixing chamber and mixing tool are fully welded. The surface roughness is also adapted to the hygienic conditions.

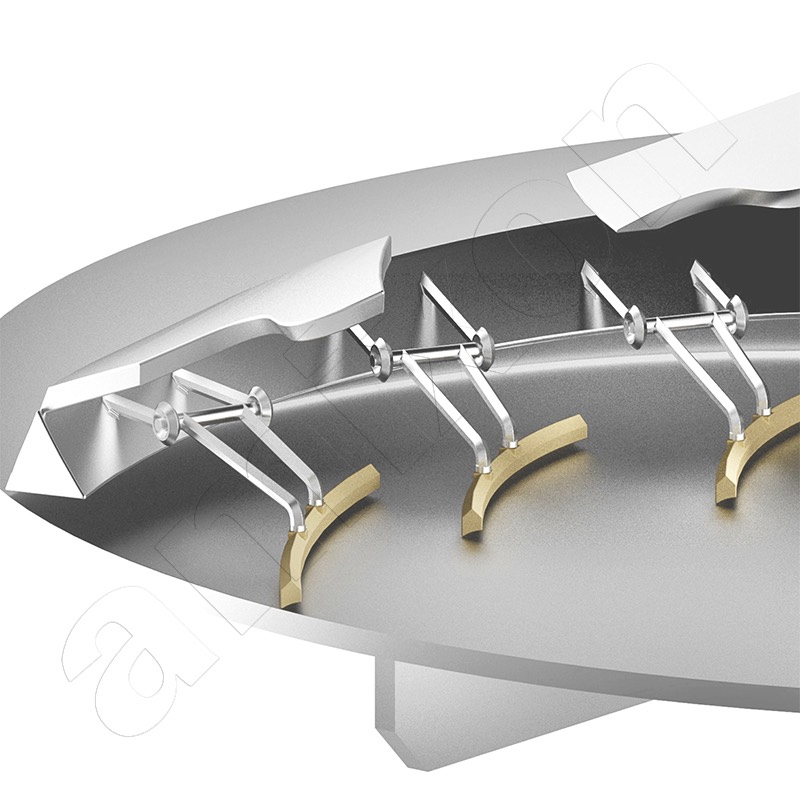

ComDisc® tools for complete discharging

ComDisc® tools are capable of completely discharging mixers with a flat bottom. During the mixing process, the ComDisc® elements float in the flow shadow through the mix. In the final phase of emptying, the ComDisc® tools are lowered and gently sweep across the floor of the mixing chamber. Then they act like windshield wipers. They are arranged at an angle and push the remaining product into the discharge outlet.

The complete discharge after each batch can open up great additional benefits for mixing businesses. Especially when constantly changing recipes are mixed.

ComDisc® tools are made of food-safe material and are particularly wear-resistant. They are captively mounted. Worn edges can be replaced inexpensively if necessary.

ComDisc® tools are capable of completely discharging mixers with a flat bottom. During the mixing process, the ComDisc® elements float in the flow shadow through the mix. In the final phase of emptying, the ComDisc® tools are lowered and gently sweep across the floor of the mixing chamber. Then they act like windshield wipers. They are arranged at an angle and push the remaining product into the discharge outlet.

The complete discharge after each batch can open up great additional benefits for mixing businesses. Especially when constantly changing recipes are mixed.

ComDisc® tools are made of food-safe material and are particularly wear-resistant. They are captively mounted. Worn edges can be replaced inexpensively if necessary.

Self-cleaning through complete discharge

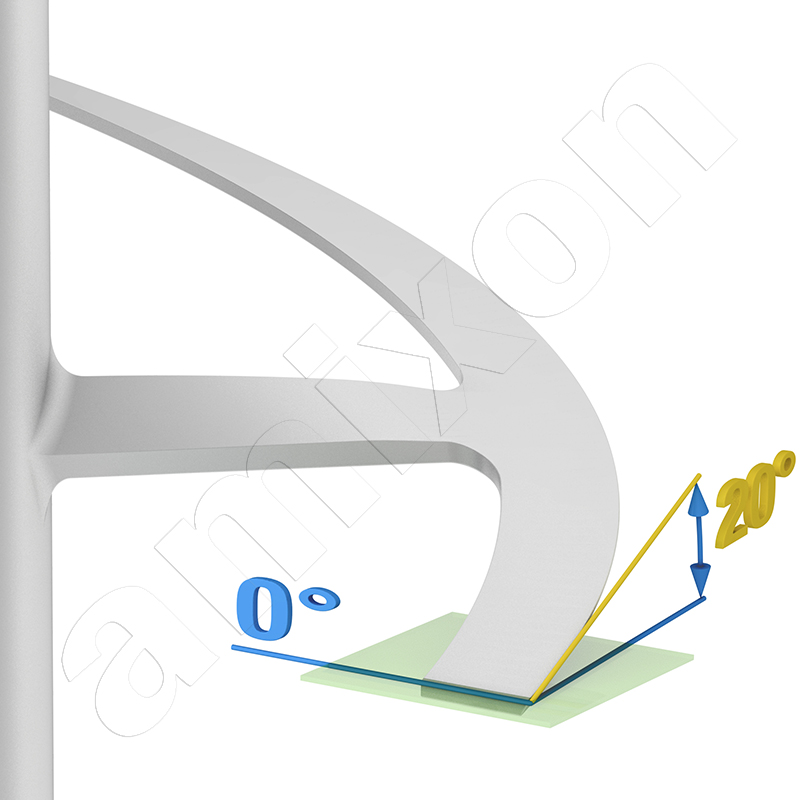

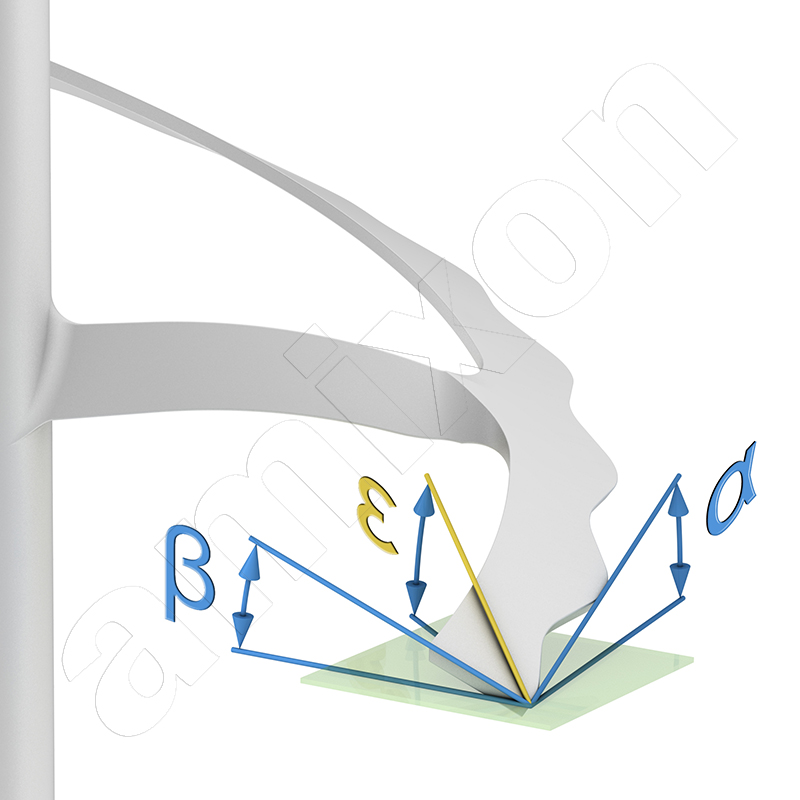

SinConvex® and SinConcave® mixing elements allow the mixing goods to flow out completely.

The mixing tools are seamlessly welded and ground. They are only driven and supported from above. The shaft bushing has a lip seal. This can be split on request and allows a worn seal to be replaced with minimal effort.

SinConvex® and SinConcave® mixing spirals combine two advantages: Optimum mixing and particularly good residual emptying.

On request, standard mixing tools of older amixon® mixers can be retrofitted to Sinconvex® or SinConcave® mixing spirals. The conversion is carried out on site. It is not necessary to dismantle the mixer.

Flat-bottom mixers can also achieve excellent levels of residual emptying if the lower mixing arm is equipped with ComDisc® tools.

SinConvex® and SinConcave® mixing elements allow the mixing goods to flow out completely.

The mixing tools are seamlessly welded and ground. They are only driven and supported from above. The shaft bushing has a lip seal. This can be split on request and allows a worn seal to be replaced with minimal effort.

SinConvex® and SinConcave® mixing spirals combine two advantages: Optimum mixing and particularly good residual emptying.

On request, standard mixing tools of older amixon® mixers can be retrofitted to Sinconvex® or SinConcave® mixing spirals. The conversion is carried out on site. It is not necessary to dismantle the mixer.

Flat-bottom mixers can also achieve excellent levels of residual emptying if the lower mixing arm is equipped with ComDisc® tools.

KwickKlamp® locking systems

An amixon® inspection door can also be cylindrically-conical. KwickKlamp® closure systems are particularly hygienic and smooth-running. When closed, they are permanently self-locking. Key transfer systems are tamper-proof and work purely mechanically. They are suitable for harsh operating conditions. They meet all requirements with regard to occupational safety.

An amixon® inspection door can also be cylindrically-conical. KwickKlamp® closure systems are particularly hygienic and smooth-running. When closed, they are permanently self-locking. Key transfer systems are tamper-proof and work purely mechanically. They are suitable for harsh operating conditions. They meet all requirements with regard to occupational safety.

Hygienic features in amixon® mixers

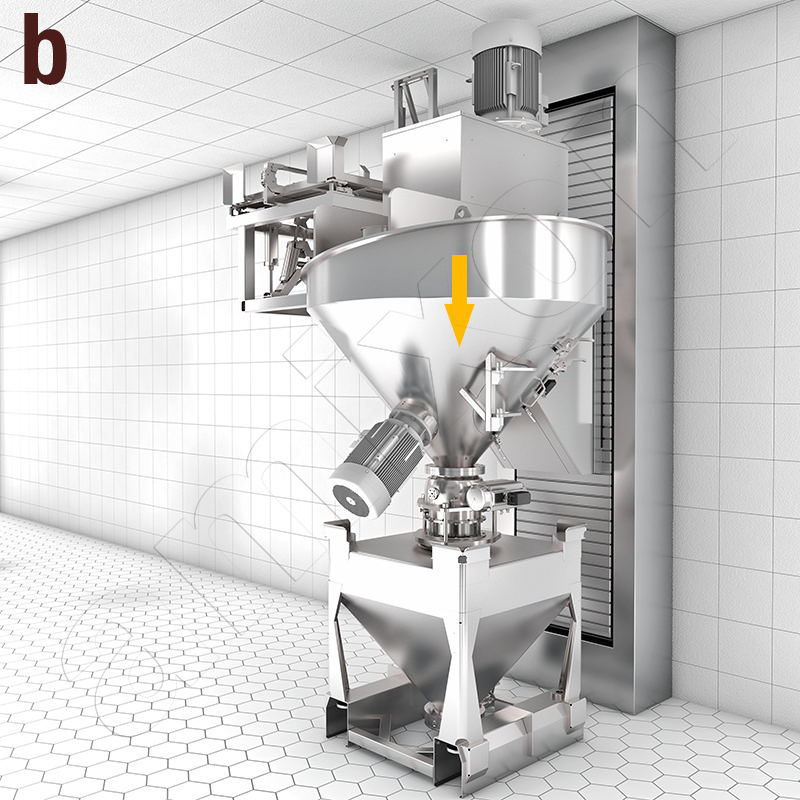

The amixon® mixing systems depicted have different areas of application. But they have the same hygiene features. One of the distinguishing features of a hygienic precision mixer is that it mixes the ingredients particularly gently. Adhesion due to heat and friction is avoided.

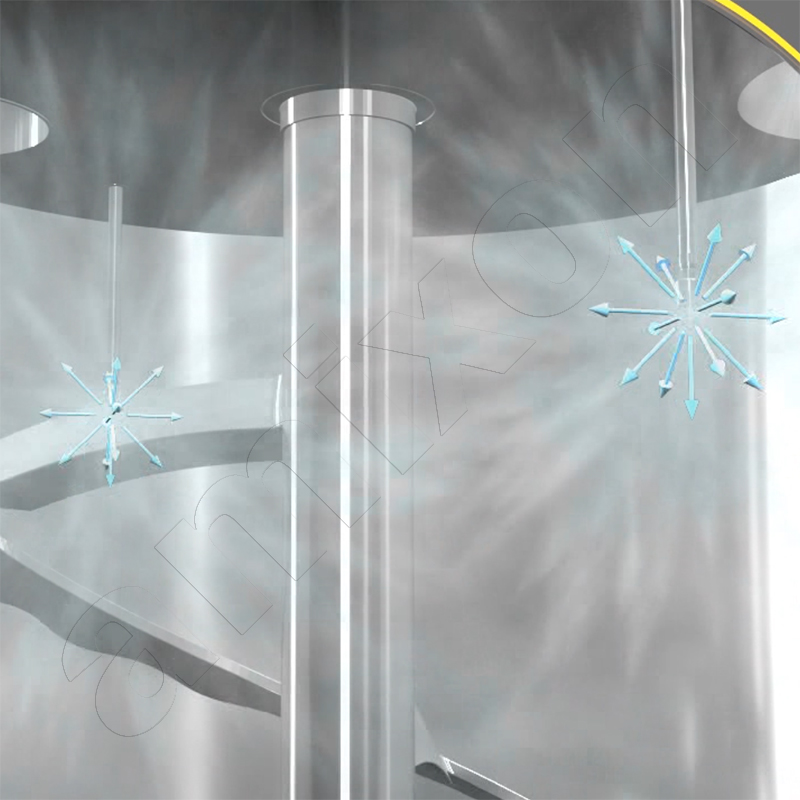

The mixing container stands upright. A helical mixing tool rotates in the center of the mixing chamber. The three-dimensional circulation of the products is carried out independently of their individual flow behavior. The mixing tool picks up the mixing goods at the perimeter of the mixing chamber and conveys them upwards. The conical design enables ideal mixing qualities even with low filling levels (5%-10%).

SinConvex® and SinConcave® mixing elements convey the mixing materials upwards in the periphery of the mixing chamber. Once at the top, the goods flow downwards in the center of the mixing chamber and drift outwards again. Dry, moist or suspended goods are mixed with ideal precision - regardless of varying particle sizes, bulk densities, flow properties and the mixer rotation frequency. An ideal mixing quality is usually achieved after 30 to 100 revolutions.

In many cases, a dry mixing plant is air-conditioned in order to reduce the moisture input from the ambient air and keep the powders cool. Particular caution is required for wet cleaning operations in the production environment. The handling of water is normally undesirable in such a production environment. In the case of wet cleaning, it must be ensured that the wet zone only refers to the interior of the mixer and that the drying vapors are removed from the room.

The amixon® mixing systems depicted have different areas of application. But they have the same hygiene features. One of the distinguishing features of a hygienic precision mixer is that it mixes the ingredients particularly gently. Adhesion due to heat and friction is avoided.

The mixing container stands upright. A helical mixing tool rotates in the center of the mixing chamber. The three-dimensional circulation of the products is carried out independently of their individual flow behavior. The mixing tool picks up the mixing goods at the perimeter of the mixing chamber and conveys them upwards. The conical design enables ideal mixing qualities even with low filling levels (5%-10%).

SinConvex® and SinConcave® mixing elements convey the mixing materials upwards in the periphery of the mixing chamber. Once at the top, the goods flow downwards in the center of the mixing chamber and drift outwards again. Dry, moist or suspended goods are mixed with ideal precision - regardless of varying particle sizes, bulk densities, flow properties and the mixer rotation frequency. An ideal mixing quality is usually achieved after 30 to 100 revolutions.

In many cases, a dry mixing plant is air-conditioned in order to reduce the moisture input from the ambient air and keep the powders cool. Particular caution is required for wet cleaning operations in the production environment. The handling of water is normally undesirable in such a production environment. In the case of wet cleaning, it must be ensured that the wet zone only refers to the interior of the mixer and that the drying vapors are removed from the room.

Inspection doors and their seals

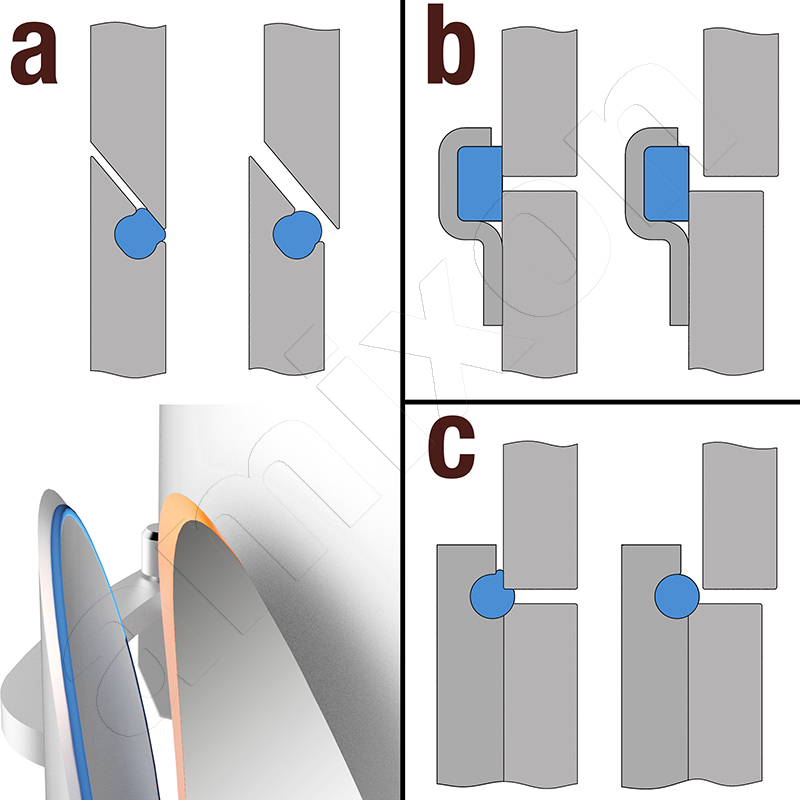

amixon® has devoted a great amount of development work to this topic and established outstanding solutions: KwickKlamp®- door latches are easy to operate and permanently self-locking.

Food and pharmaceutical companies often use their mixers for 30 years or more. The mixing jobs change frequently, sometimes around 15 times per day. - The inspection doors are opened and closed countless times for cleaning purposes. This places high demands on an inspection door:

- No dead space

- Permanent gas and water tightness

- Smooth closing with little effort

- Uniform contact pressure

- Minimal stress on the polymer seal

- Simple replacement of the sealing rings

Other mixer manufacturers use door seals like the one shown on the right. amixon® manufactures the OmgaSeal® version ( pictured left). OmgaSeal® seals without dead space and offers the highest standard of hygiene.

amixon® has devoted a great amount of development work to this topic and established outstanding solutions: KwickKlamp®- door latches are easy to operate and permanently self-locking.

Food and pharmaceutical companies often use their mixers for 30 years or more. The mixing jobs change frequently, sometimes around 15 times per day. - The inspection doors are opened and closed countless times for cleaning purposes. This places high demands on an inspection door:

- No dead space

- Permanent gas and water tightness

- Smooth closing with little effort

- Uniform contact pressure

- Minimal stress on the polymer seal

- Simple replacement of the sealing rings

Other mixer manufacturers use door seals like the one shown on the right. amixon® manufactures the OmgaSeal® version ( pictured left). OmgaSeal® seals without dead space and offers the highest standard of hygiene.

HACCP was initiated by NASA in 1958

The idea of "Hazard Analysis and Critical Control Points" originated at NASA in 1958. The aim was to develop guidelines for the production, storage and processing of space food.

The principles were later adopted by the Codex Alimentarius Commission of the WHO: Hazard analysis - critical control points - limit values - continuous monitoring - corrective measures - documentation - regular verification.

Process machines for food and pharmaceutical production meet minimum hygiene requirements in order to implement HACCP. The EHEDG , for example, could also offer its services here. The "European Hygienic Engineering and Design Group" pursues the goal of promoting food safety. The members of the EHEDG are mechanical engineering companies, food producers, research institutes and health authorities. In this respect, it also advises European committees on the development of statutory hygiene guidelines.

For example, the EHEDG evaluates construction materials and their industry-specific suitability. A number of mechanical engineers are contributing improved design ideas to the EHEDG's decision-making bodies. It can carry out practical cleaning tests and issue hygienic design certificates for good cleanability.

The EHEDG is endeavouring to exchange information with the US government agency NSF (National Sanitation Foundation*) and the non-profit American organization 3-A SSI (3-A Sanitary Standards**) in order to establish common views transatlantically.

*) The NSF is a US government agency for basic research and education in food technology.

**) The 3-A SSI is a non-profit organization in the USA that focuses on good hygienic design in the food, beverage and pharmaceutical industries. It also certifies components based on strict theoretical design requirements, material specifications and surface finishes. However, qualifications through practical cleaning tests are not part of the 3-A SSI certificates.

The idea of "Hazard Analysis and Critical Control Points" originated at NASA in 1958. The aim was to develop guidelines for the production, storage and processing of space food.

The principles were later adopted by the Codex Alimentarius Commission of the WHO: Hazard analysis - critical control points - limit values - continuous monitoring - corrective measures - documentation - regular verification.

Process machines for food and pharmaceutical production meet minimum hygiene requirements in order to implement HACCP. The EHEDG , for example, could also offer its services here. The "European Hygienic Engineering and Design Group" pursues the goal of promoting food safety. The members of the EHEDG are mechanical engineering companies, food producers, research institutes and health authorities. In this respect, it also advises European committees on the development of statutory hygiene guidelines.

For example, the EHEDG evaluates construction materials and their industry-specific suitability. A number of mechanical engineers are contributing improved design ideas to the EHEDG's decision-making bodies. It can carry out practical cleaning tests and issue hygienic design certificates for good cleanability.

The EHEDG is endeavouring to exchange information with the US government agency NSF (National Sanitation Foundation*) and the non-profit American organization 3-A SSI (3-A Sanitary Standards**) in order to establish common views transatlantically.

*) The NSF is a US government agency for basic research and education in food technology.

**) The 3-A SSI is a non-profit organization in the USA that focuses on good hygienic design in the food, beverage and pharmaceutical industries. It also certifies components based on strict theoretical design requirements, material specifications and surface finishes. However, qualifications through practical cleaning tests are not part of the 3-A SSI certificates.

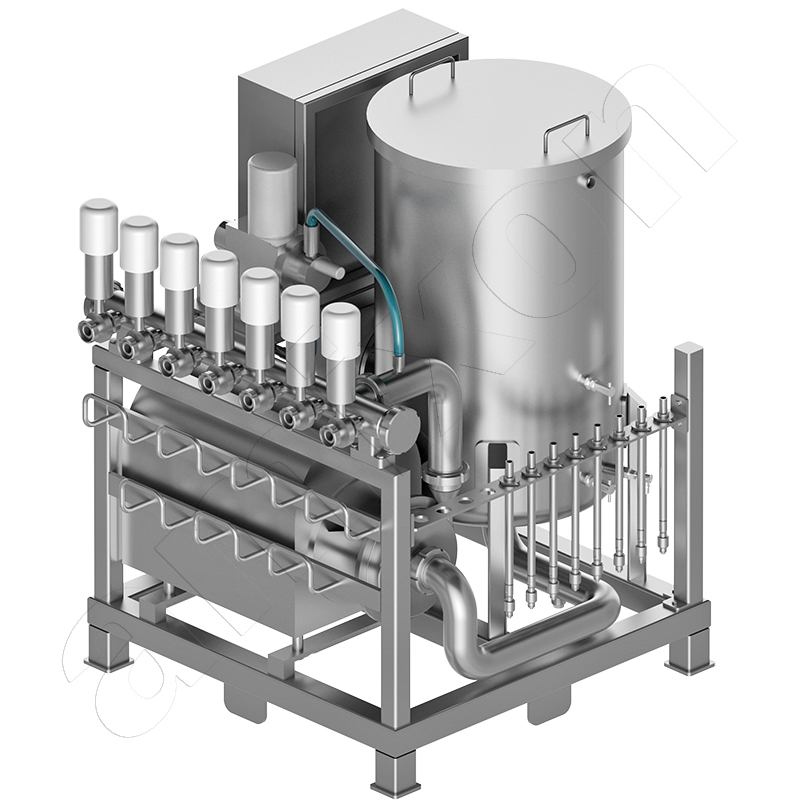

"Multistep" for complex instant products

Multi-stage mixing processes are often used for complex mixtures of substances in the flavor and spice industry: First, a partial filling with ground, finely dispersed raw materials such as starch, cereal derivatives, salt, sugar, ground spices, fillers and stabilizers takes place. During the intensive mixing phase, liquids such as baking extracts, fats, oils, lecithins and oleoresins are added in measured doses. The mixing tools are switched off immediately after reaching the ideal mixing quality. Sensitive components (dried vegetables, spray-dried agglomerates, visible spices, freeze-dried meat preparations) are added. This is followed by a phase of particularly gentle "folding in" at a low mixer speed. This preserves the granulometry of the sensitive components. The bulk goods are then discharged while the mixer rotates slowly. Free-flowing products are emptied down to the last residue.

This "Multistep" process can replace small mixers in which so-called premixes are produced.

Cone mixer: Optimum mixing quality even at low filling levels

Multi-stage mixing processes are often used for complex mixtures of substances in the flavor and spice industry: First, a partial filling with ground, finely dispersed raw materials such as starch, cereal derivatives, salt, sugar, ground spices, fillers and stabilizers takes place. During the intensive mixing phase, liquids such as baking extracts, fats, oils, lecithins and oleoresins are added in measured doses. The mixing tools are switched off immediately after reaching the ideal mixing quality. Sensitive components (dried vegetables, spray-dried agglomerates, visible spices, freeze-dried meat preparations) are added. This is followed by a phase of particularly gentle "folding in" at a low mixer speed. This preserves the granulometry of the sensitive components. The bulk goods are then discharged while the mixer rotates slowly. Free-flowing products are emptied down to the last residue.

This "Multistep" process can replace small mixers in which so-called premixes are produced.

Cone mixer: Optimum mixing quality even at low filling levels

© Copyright by amixon GmbH