To what extent do you consider large inspection doors and easy-to-use door latches important when it comes to ergonomics, work safety and hygiene?

In this blog article, we discuss questions about inspection doors/inspection flaps on powder mixers and bulk solids systems.

It is generally an advantage if a powder mixer has large inspection doors:

- easy access to the mixing chamber

- Manual removal of mixing material residues is made easier

- Manual cleaning of the mixing chamber is made easier

- Checking the cleaning result is favoured

- Maintenance is made easier: seals can be easily replaced on the mixer shaft and the outlet fitting

- The reconditioning of worn mixing tools is simplified

- Large mixers can be easily accessed

Inspection door with high strength and rigidity

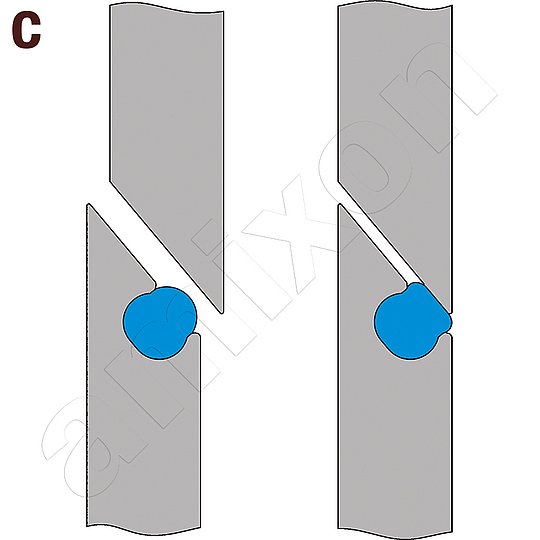

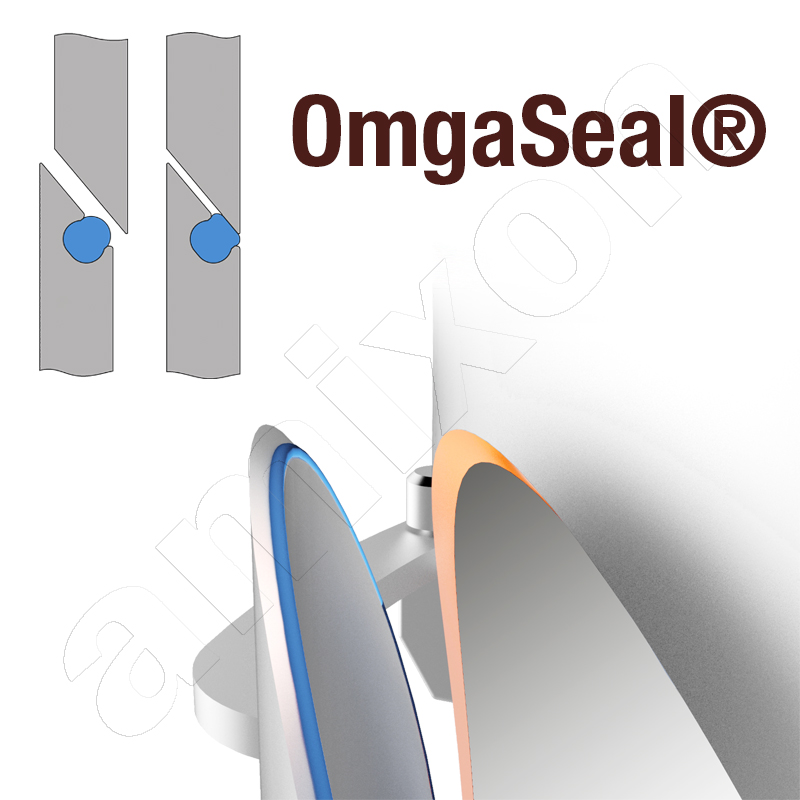

Large inspection doors must have a high degree of rigidity, only then is a permanently gas-tight seal possible. The movement of the mixed material creates static and dynamic loads that act on the mixing chamber and the door. Both components must have sufficient rigidity. No relative movements may occur between them.

In addition, doors with high rigidity require that the pole seals are loaded evenly and gently. The elasticity of the polymer seal is maintained for a long time. In particular, they are not crushed or sheared.

Large inspection doors must have a high degree of rigidity, only then is a permanently gas-tight seal possible. The movement of the mixed material creates static and dynamic loads that act on the mixing chamber and the door. Both components must have sufficient rigidity. No relative movements may occur between them.

In addition, doors with high rigidity require that the pole seals are loaded evenly and gently. The elasticity of the polymer seal is maintained for a long time. In particular, they are not crushed or sheared.

Can the door lock on the amixon® mixer open unintentionally?

The KwickKlamp® door lock can never open by itself. It closes "self-locking". Self-locking means that the lever can never be operated from the load side.

On the other hand, opening and closing from the operating side is quick, easy and convenient. Handling the KwickKlamp® door latch is particularly ergonomic. It has been specially developed for hygienic applications.

The closure of an inspection door without dead space must be particularly suitable. The contact pressure on the polymer seal must be defined. Each closing process must be carried out with the same contact pressure. amixon has designed the KwickKlamp® so that the contact pressure can be adjusted and locked.

The KwickKlamp® door lock can never open by itself. It closes "self-locking". Self-locking means that the lever can never be operated from the load side.

On the other hand, opening and closing from the operating side is quick, easy and convenient. Handling the KwickKlamp® door latch is particularly ergonomic. It has been specially developed for hygienic applications.

The closure of an inspection door without dead space must be particularly suitable. The contact pressure on the polymer seal must be defined. Each closing process must be carried out with the same contact pressure. amixon has designed the KwickKlamp® so that the contact pressure can be adjusted and locked.

If the mixer is wet-cleaned, does the seal need to be replaced?

The vast majority of our customers do not change the seal after wet cleaning.

The vast majority of our customers do not change the seal after wet cleaning.

amixon® has created excellent solutions for permanently tight inspection doors

- The mixing chamber and inspection door have a thick-walled design, which increases strength and rigidity.

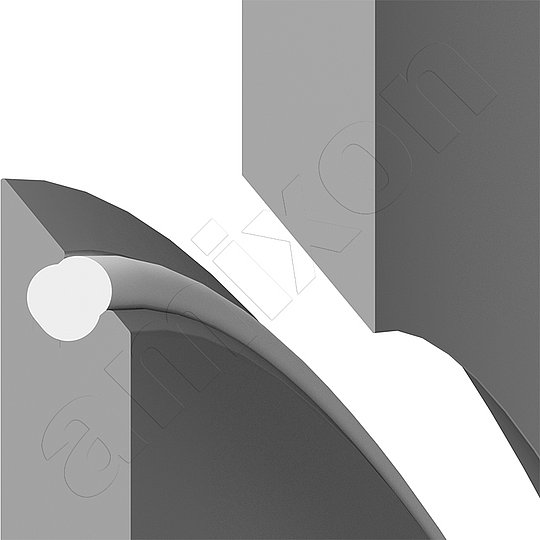

- The groove is curved. The radius of the curvature corresponds to the diameter of the seal. The curvature is so pronounced that it has a firm grip on the seal. It cannot be lost. On the other hand, it can be easily replaced.

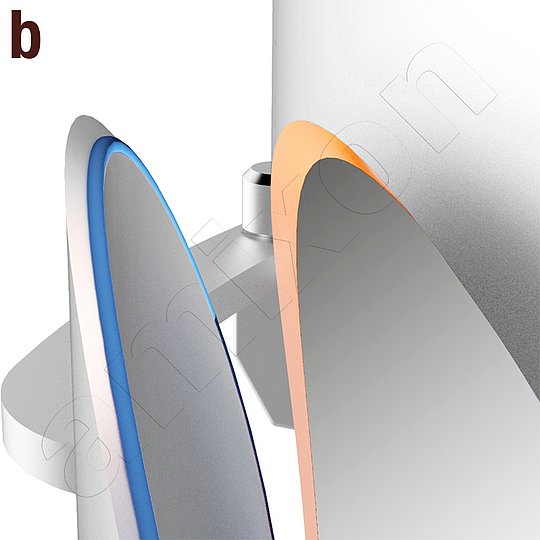

- The inspection door is round or oval. The contact plane between the door and the mixing chamber opening is inclined. This allows the seal to be positioned particularly close to the mix. As a result, the amixon® inspection door is free of dead space.

- amixon® inspection doors can also be installed in the transition area between the cylinder and cone.

- The mixing chamber and inspection door have a thick-walled design, which increases strength and rigidity.

- The groove is curved. The radius of the curvature corresponds to the diameter of the seal. The curvature is so pronounced that it has a firm grip on the seal. It cannot be lost. On the other hand, it can be easily replaced.

- The inspection door is round or oval. The contact plane between the door and the mixing chamber opening is inclined. This allows the seal to be positioned particularly close to the mix. As a result, the amixon® inspection door is free of dead space.

- amixon® inspection doors can also be installed in the transition area between the cylinder and cone.

© Copyright by amixon GmbH