Powder agglomeration in the amixon® Ring-layer mixing granulator

Agglomeration is a natural process that we can also observe in baking, for example. If we stir flour and wet it with a steady stream of water, then the flour will be dust-free at first. Dust particles are bound. Finally, irregular agglomerates form. If the water is continuously added, the agglomerates compact into lumps, ultimately forming a dough.

We can also understand agglomeration/ built-up granulation without tools: We do dusty work and then vigorously rub our palms against each other. The small crumbs produced this way are the result of built-up agglomeration. The finest particles are compacted and roll up; in the presence of moisture correspondingly faster than in the dry state. Particles form so-called liquid bridges at the contact points. Short bridges can bind particles together very tightly. In the ideal case, rounded agglomerates build up.

Dry agglomeration: When we empty the filter of a vacuum cleaner, we notice that many fine particles are accumulated there, many of which are even smaller than the mesh size of the vacuum cleaner filter. The reason why the finest particles did not pass through the filter lies in the interparticle adhesive forces. These electrostatic forces and van der Waals forces are more effective the smaller the particles are. They are many powers of ten greater than the gravitational force acting on them. They can float in the air for a very long time.

Collected filter dust does not necessarily have to be waste. Such a filtrate can also be valuable, for example if it is obtained from pyrolysis. This is the case when carbonaceous substances change to soot in the absence of oxygen at high temperatures. Industrially produced soot consists of nanoparticles. It is used as a black pigment in photocopiers, in the printing and paint industries, but also as a stabilizer in rubber processing. Car tires, for example, would age quickly without the addition of soot.

Agglomeration always takes place to a greater or lesser extent when a particle collective is dispersed. Depending on the composition of the material, built-up granulation can become dominant during mixing if the powder is wetted with a suitable binder liquid. Powders that have a broad particle size distribution are easier to agglomerate than monodisperse powders. An upstream grinding process can then promote agglomeration. Sometimes the particles involved have to be mixed and rubbed together particularly intensively to initiate the "grain build-up". Such a mixing process requires high-speed tool movements and increased energy input. Mixing agglomeration makes bulk materials low in dust, easy to convey, easy to transport and easy to pack by means of compaction and rounding. Dusts reduce their volume. Heterogeneous compositions of substances that tend to segregate can be fixated.

Question from a customer: To what extent do agglomerated powders from the spraying and fluid bed processes differ from agglomerates from a ring-layer mixing granulator?

Answer from amixon®: Both methods are well suited for binding dust. The agglomerates from a mixing granulator are usually more dense and less porous. They differ significantly from the porous agglomerates from fluidized bed agglomeration. The comparatively expensive fluid bed process is often used when the powders need to sink quickly in a liquid, be quickly dispersible, and be wettable without lumps. Fluidized bed agglomeration improves the so-called instant properties of powders.

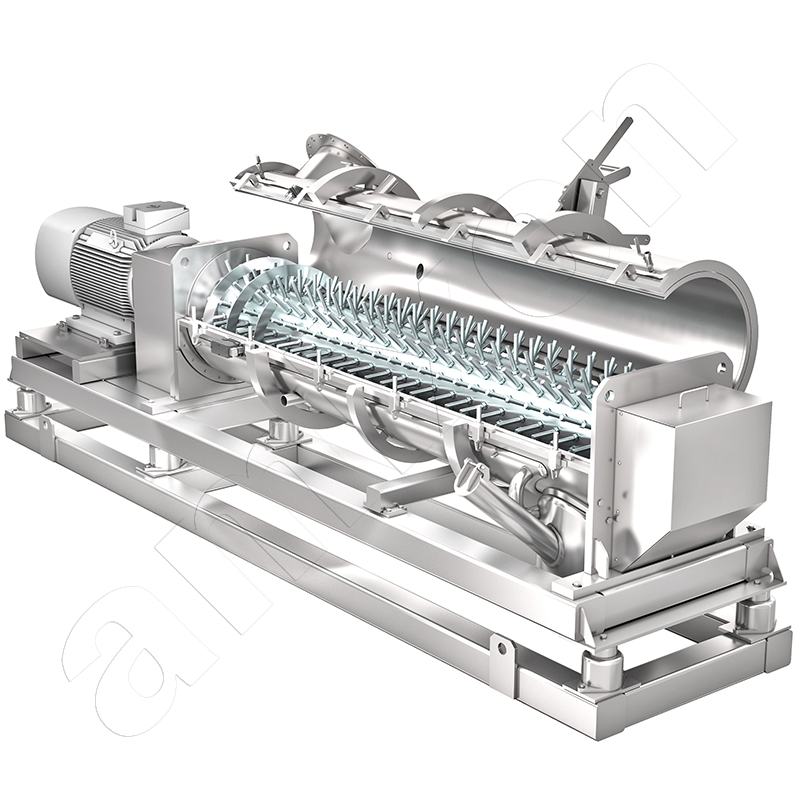

For many bulk materials, a more cost-effective grain enlargement process is desired. Continuous ring layer agglomeration represents such a process. However, the development of an economical granulation process is not trivial. Not every powder is suitable for building up a stable agglomerate. Choosing a suitable binder liquid is not easy, because the additive should not affect the chemical composition of the end product. In the simplest case, water is used as a binder. Sometimes an adhesive substance such as molasses may be added. The amount of added liquid should be kept as low as possible. This is because, with a few exceptions, a thermal drying process takes place after the buildup agglomeration. Only in a few cases can powders be agglomerated in the ring-layer mixing granulator without the addition of liquid binders. As a rule, the powders have to be intensively agitated by turbulence, compaction and shearing. In practice, this is done continuously. The amixon® mixer shown here can build up very evenly sized agglomerates.

Answer from amixon®: Both methods are well suited for binding dust. The agglomerates from a mixing granulator are usually more dense and less porous. They differ significantly from the porous agglomerates from fluidized bed agglomeration. The comparatively expensive fluid bed process is often used when the powders need to sink quickly in a liquid, be quickly dispersible, and be wettable without lumps. Fluidized bed agglomeration improves the so-called instant properties of powders.

For many bulk materials, a more cost-effective grain enlargement process is desired. Continuous ring layer agglomeration represents such a process. However, the development of an economical granulation process is not trivial. Not every powder is suitable for building up a stable agglomerate. Choosing a suitable binder liquid is not easy, because the additive should not affect the chemical composition of the end product. In the simplest case, water is used as a binder. Sometimes an adhesive substance such as molasses may be added. The amount of added liquid should be kept as low as possible. This is because, with a few exceptions, a thermal drying process takes place after the buildup agglomeration. Only in a few cases can powders be agglomerated in the ring-layer mixing granulator without the addition of liquid binders. As a rule, the powders have to be intensively agitated by turbulence, compaction and shearing. In practice, this is done continuously. The amixon® mixer shown here can build up very evenly sized agglomerates.

Question from a customer: Our goal is to produce agglomerates that have a defined grain size distribution. What equipment requirements must be met in order to be able to granulate a powder mixture evenly and effectively?

Answer from amixon®: Sometimes the "success window" is very small and hard to find. Especially when the use of the liquid binders should be as low as possible. A lot of experience and experiments can help here. In our opinion, an agglomeration system should have several characteristics:

- The rotating shaft is equipped with a particularly large number of mixing tools.

- The distance between the tools and the wall should be defined.

- In addition, there are process-related requirements for the dosing systems. The powder feeders as well as the liquid feeders should have a very high "short time accuracy", considering the short residence time in the granulator.

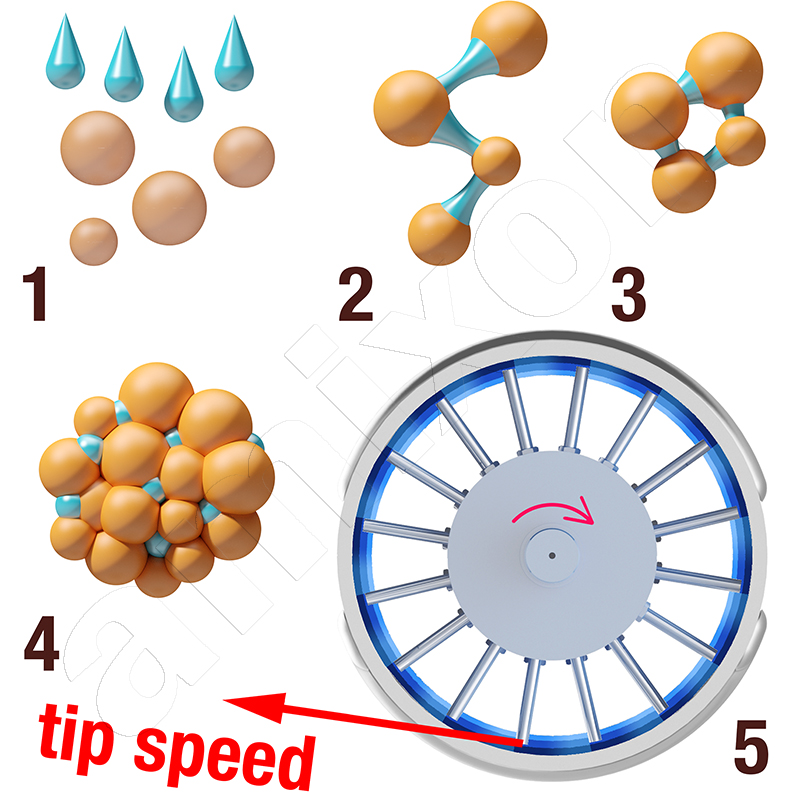

1) Powder wetting 2) Liquid bridges 3) Agglomerate nucleus forms 4) Moist agglomerate 5) Agitator shaft (mounted horizontally) with many pin tools rotates at high speed. The distance between the pins and the mixing space is the same everywhere.

Answer from amixon®: Sometimes the "success window" is very small and hard to find. Especially when the use of the liquid binders should be as low as possible. A lot of experience and experiments can help here. In our opinion, an agglomeration system should have several characteristics:

- The rotating shaft is equipped with a particularly large number of mixing tools.

- The distance between the tools and the wall should be defined.

- In addition, there are process-related requirements for the dosing systems. The powder feeders as well as the liquid feeders should have a very high "short time accuracy", considering the short residence time in the granulator.

1) Powder wetting 2) Liquid bridges 3) Agglomerate nucleus forms 4) Moist agglomerate 5) Agitator shaft (mounted horizontally) with many pin tools rotates at high speed. The distance between the pins and the mixing space is the same everywhere.

Question from a customer: Do you think that the controlling behavior of the powder feeders and the controlling behavior of the liquid feeders must take place within very narrow limits?

Answer from amixon®: Yes, that is exactly what is meant. If the pin mixer rotates particularly fast, then the continuously added mixing goods also move quickly and are distributed evenly over the entire perimeter. The mixing goods are rotated, rolled, mixed, accelerated and compacted. High peripheral speeds of 10 to over 25 m/s mean that the centrifugal acceleration can be hundreds of times greater than the gravitational acceleration. The pressure on the powder ring layer increases with the square of the peripheral speed. The many pins generate shear, compaction and impact in the ring layer. Any liquid additives present act as a binder and create round, stable granules. These tend to be smaller and denser the faster the pins rotate and the less liquid is added.

Answer from amixon®: Yes, that is exactly what is meant. If the pin mixer rotates particularly fast, then the continuously added mixing goods also move quickly and are distributed evenly over the entire perimeter. The mixing goods are rotated, rolled, mixed, accelerated and compacted. High peripheral speeds of 10 to over 25 m/s mean that the centrifugal acceleration can be hundreds of times greater than the gravitational acceleration. The pressure on the powder ring layer increases with the square of the peripheral speed. The many pins generate shear, compaction and impact in the ring layer. Any liquid additives present act as a binder and create round, stable granules. These tend to be smaller and denser the faster the pins rotate and the less liquid is added.

Question from a customer: Can the granulation process described above also take place in batches?

Answer from amixon®: Unfortunately no, the amixon® ring layer mixer shown here can only be operated continuously. It is primarily used when processes are time-critical. This means that mechanical agitation takes place briefly and particularly intensively. Sometimes a dwell time of less than 10 seconds is sufficient. This shows that the filling level is comparatively low. amixon® has written explanatory blog articles regarding your question.

Question from a customer: Somehow, the ring-layer mixing pelletizer with its horizontally mounted mixer shaft appears to be an exception in the amixon® product range. All other amixon® mixers are equipped with vertically mounted mixing tools. Is that a coincidence?

Answer from amixon®: The situation is historical. Ring layer mixing granulators of the RMG type were developed by us more than 25 years ago. At that time, we had specialized our production on this sophisticated machine design and had the privilege to supply them to several carbon black plants worldwide. Later, ring-layer mixing granulators were also applied in other industries where bulk materials are granulated to a high degree of quality: Surfactants for washing-active substances, color pigments, peat, fertilizers, foundry covering compounds, baking agents, instant beverages, potato powder, enzymes, medical active ingredients, tablet compounds, pesticides, and other goods - some of which are also toxic.

The ring-layer mixer-granulator system is very advanced and has been tried and tested many times. However, amixon® is not pursuing any further developments at the moment. For continuous mixing tasks we recommend the amixon® mixing system AMK with a vertically mounted mixer shaft.

Answer from amixon®: The situation is historical. Ring layer mixing granulators of the RMG type were developed by us more than 25 years ago. At that time, we had specialized our production on this sophisticated machine design and had the privilege to supply them to several carbon black plants worldwide. Later, ring-layer mixing granulators were also applied in other industries where bulk materials are granulated to a high degree of quality: Surfactants for washing-active substances, color pigments, peat, fertilizers, foundry covering compounds, baking agents, instant beverages, potato powder, enzymes, medical active ingredients, tablet compounds, pesticides, and other goods - some of which are also toxic.

The ring-layer mixer-granulator system is very advanced and has been tried and tested many times. However, amixon® is not pursuing any further developments at the moment. For continuous mixing tasks we recommend the amixon® mixing system AMK with a vertically mounted mixer shaft.

Tests in the test center are essential: In order to achieve a good granulation process with an amixon® ring-layer mixing granulator, many parameters must align with each other.

This includes:

- the selection of suitable mixing tools,

- the correct rotation frequency,

- the amount and type of liquid additives

- many more

Without trials, it is almost impossible to make statements about the efficiency and quality of agglomeration. Smaller and larger testing machines as well as dosing and wetting systems for liquid components are available in the amixon® test center.

We cordially invite you to visit us with your products. For a conclusive test, we recommend to provide at least 500 liters of raw material.

This includes:

- the selection of suitable mixing tools,

- the correct rotation frequency,

- the amount and type of liquid additives

- many more

Without trials, it is almost impossible to make statements about the efficiency and quality of agglomeration. Smaller and larger testing machines as well as dosing and wetting systems for liquid components are available in the amixon® test center.

We cordially invite you to visit us with your products. For a conclusive test, we recommend to provide at least 500 liters of raw material.

© Copyright by amixon GmbH