Nutrient substrates for mushroom cultivation: Sterilise and "inoculate"

Noble mushrooms have a unique taste, which is why their culinary value is highly valued. As a delicacy, they have become an indispensable part of the upscale cuisine.

The best-known noble mushrooms are truffles, morels, porcini mushrooms and chanterelles, mushrooms, velvet caps, shiitakes, seitlings and shimeji. Truffles are among the most expensive noble mushrooms. They grow underground in symbiosis with the roots of certain tree species. Some noble and useful mushrooms are cultivated on substrates. Poisonous and mouldy mushrooms can cause severe poisoning.

On the other hand, certain moulds play an important role in medicine. Penicillium chrysogenum is a type of mould that is cultivated in fermenters and used to obtain penicillin.

Steam sterilisation of substrates

So-called growing media such as sand, wood chips, peat, used coffee grounds or prepared soil influence the growth and taste of the respective mushroom variety.

The microbiological preparation (pasteurisation) of the culture medium must be carried out gently but thoroughly. The growing medium must not be contaminated in any way.

The amixon® vacuum mixer dryer/sterile reactor effectively sterilises dry, moist and suspended bulk materials.

- The substrate is introduced into the mixer dryer/reactor. It is mixed slowly and gently. The particle size distribution should not be changed.

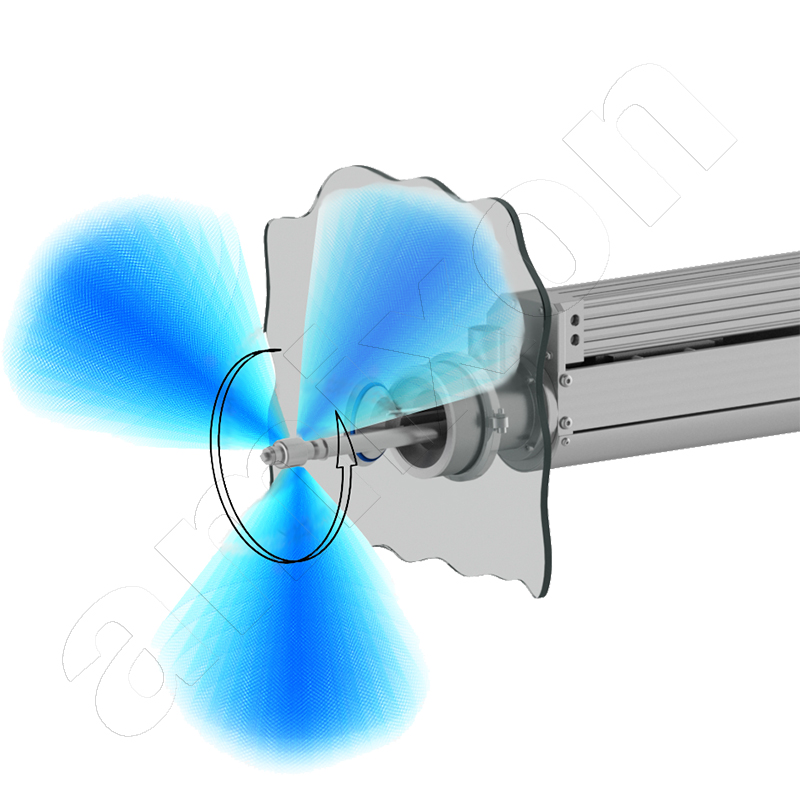

- After filling, the mixing chamber is heated and evacuated, then sterile steam is introduced at several points simultaneously and an overpressure is built up in the mixing chamber. The thermal energy of the water vapour is released by condensation on the surface of the substrate particles. The germs in and on the substrate particles are spontaneously heated and killed.

When heating up the reactor, the desired sterilisation temperature must be taken into account. The more pressure-resistant the sterile reactor is built, the higher the substrates can be heated.

The heated surfaces of the entire mixing chamber and the mixing tool ensure that the water vapour only condenses on the substrate. Water has a very high enthalpy of evaporation. During condensation, a lot of heat energy is transferred to the substrate very efficiently.

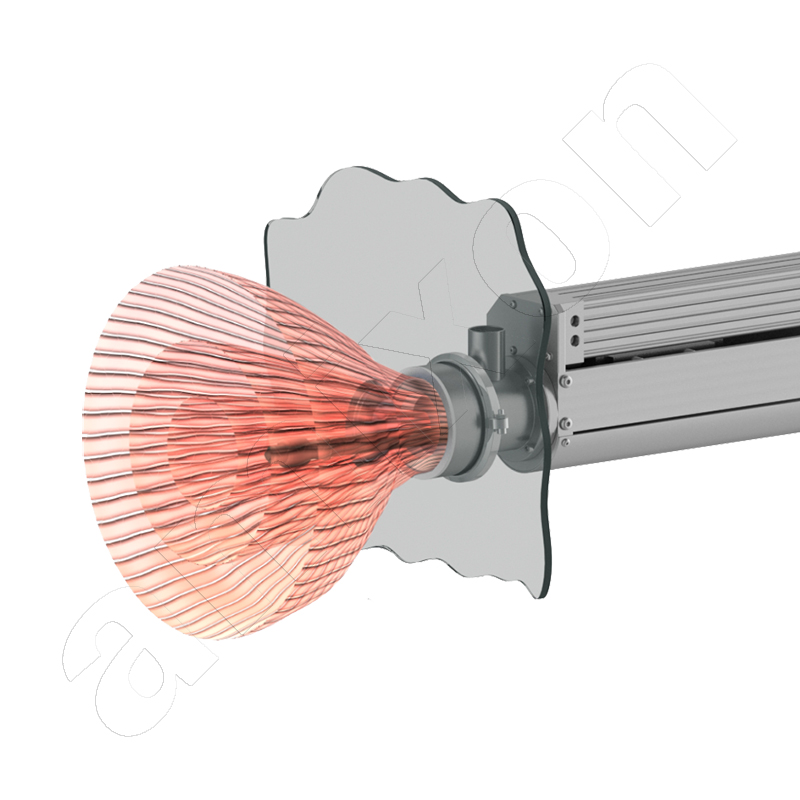

When the sterilisation target is reached, the moisture must be removed from the substrate. The substrate must be cooled down before sterile packaging. Both drying and cooling are done effectively through the use of vacuum. The drying process is very fast and efficient.

amixon® mixers/vacuum dryers/sterile reactors can be conical or cylindrical.

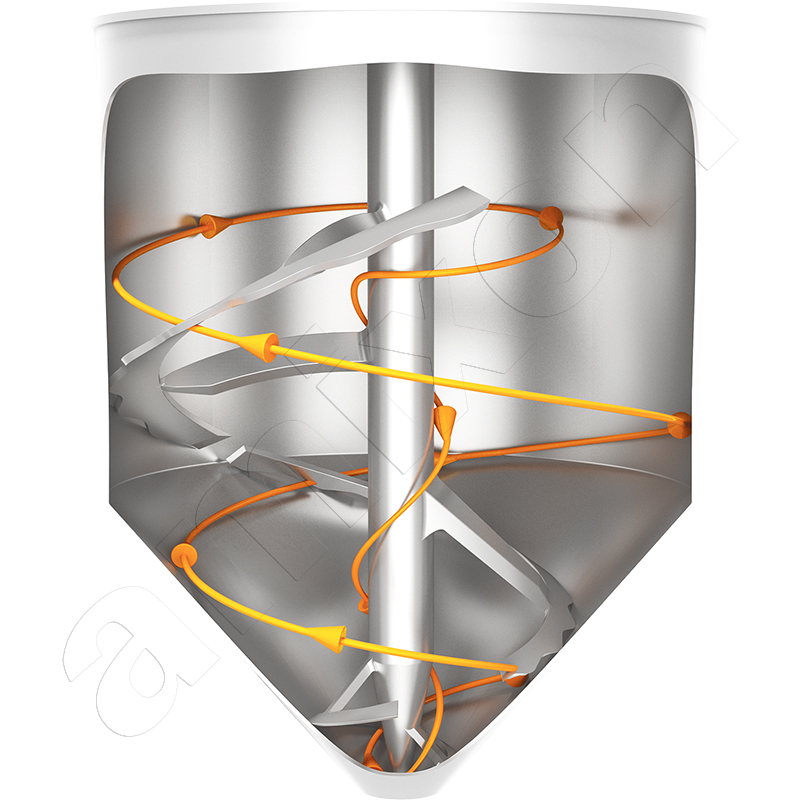

Product flow through three-dimensional rearrangement in the amixon® conical mixer

Question from a customer to amixon®: Does amixon® also deal with the so-called "vaccination" of substrates?

Response: Yes, indeed. Optionally, the dried and sterilised sewing substrate can be "inoculated" with the target mycelium and homogeneously mixed before filling. The filling process is very sensitive because of the risk of unwanted germ introduction. In the amixon® apparatus, an ideal equal distribution of the solid and liquid components is ensured.

Read more about mixing liquids into solids here!

Question from a customer to amixon®: How is the mixer/dryer/steriliser cleaned after emptying the culture medium?

Answer: amixon® process machines meet the highest hygiene standards. They are microbiologically controllable.

The processes

- Cleaning,

- Sterilisation and

- Drying

are carried out automatically in the closed state.

Learn more about solid-state fermenters here!

Question from a customer to amixon®: What testing facilities can you offer?

Response: We cordially invite you to visit our technical centre. From more than 35 test machines, we jointly select the most suitable process plant for you. This way you can be sure of the best results in advance.

A visit to the amixon® production is also definitely interesting. With the exception of engines and gearboxes, we manufacture all components ourselves in Paderborn.

© Copyright by amixon GmbH