Powder mixers and sterilisation equipment for foodstuffs and stabilisers

Powdered stabilisers are compact, easy to dose and have a significantly longer shelf life than their liquid counterparts. They can be processed automatically, provided they are low in dust and flow well. Their rheology must be process-reliable. This is exactly where amixon® comes in. Our precision mixers optimise the flow properties of even the most difficult powders and produce absolutely homogeneous mixtures without dust formation. The particle structure is retained.

On request, amixon® sterilisation equipment can sterilise powdery goods and dry them under vacuum – hygienically, gently and efficiently.

amixon® mixers are based on our own patents.

- They process large and small batches precisely, quickly and without residue.

- Even with a batch size of 100 m³, Gyraton® mixing silos achieve ideal homogeneity – and with astonishingly low drive power.

- They mix particularly gently.

- They mix intensively and deagglomerate.

- They improve flowability, which is advantageous for automated filling processes.

- Mixers from amixon® improve the instantaneous behaviour of powdery stabilisers. This is crucial if they are to be dispersed or dissolved later in a high-shear liquid mixer.

- They can agglomerate powdery stabilisers.

- They clean themselves automatically – dry or wet.

- They meet the highest hygiene standards

- – in some cases exceeding EHEDG standards.

amixon® mixers. That means: Made in Germany – individually designed and precisely tailored to your products. amixon® stands for hygienic and technologically superior solutions in food production.

Sanitary mixers and food safety compliance

amixon®industrial food mixers are specially engineered to comply with even the most demanding food safety legislation and certification programs, including 3-A, ATEX, GMP, EHEDG, FDA, USDA, and more.

But beyond mere compliance, hygienic design is at the core of every amixon® food mixer and blender:

- CleverCut® inspection doors eliminate deadspace and provide easy access to the mixing chamber, facilitating fast cleaning and drying between batches with CIP techniques.

- Tilted SinConvex® mixing blades discourage the buildup of material fines and residue, increasing discharge yields and simplifying cleaning.

- Vertically mounted agitator shafts are sealed only from the top, eliminating contact between the seal and the bulk materials.

With global testing centers located in Germany, the United States, India, Thailand, and Japan, our engineers collaborate with you to develop sanitary food mixers tailored to your product and compliance requirements, no matter which food safety regulatory body you answer to.

Dry ingredient mixers for food processing

amixon® food grade mixers are highly versatile machines suitable all sorts of dry, moist, and viscous food ingredients. They have adjustable mixing settings and are capable of performing a wide range of processing techniques needed in industrial food manufacturing.

From intensive deagglomeration to gentle homogenization, from tumble growth agglomeration to low-temperature vacuum drying, this wide range of applications have made amixon® mixing equipment indispensable to industrial food manufacturers of all kinds:

Instant soups and sauces

Complex recipes consisting of powdered components of varying sizes, such as gently dried vegetables, spices, extracts, stabilizers, and enzymes, are mixed evenly and gently without segregation or particle size reduction. The subsequent packaging takes place under inert conditions to optimally preserve the aroma, color, and functionality of the ingredients.

Industrial baking mixes

Fats, oils, baking extracts, lecithins, and flavors are evenly incorporated into the powdered ingredients in the mixer. This ensures homogeneous wetting of the mixture without lumping or sticking. The product remains cool, free-flowing, and stable in storage for long periods of time.

Spices, herbs, and spice mixtures

Fresh herbs and spices are dried, sterilized, and ground. The process is designed to preserve their essential oils. They are then gently and homogeneously blended with other ingredients (solid or liquid) in the amixon® mixer. Fragile ingredients such as flowers, leaf pieces, or granulated extrudates are often added. The end products are loose, free-flowing, and dust-free. They can be packaged automatically and conveniently without losing their functional properties. Our mixers can be sterilized in various ways to ensure they are germ-free. amixon® sterile reactors can even be used to sterilize powder mixtures, tea, herbs, or seeds.

Baby food, infant formula, protein powder, and dietary supplements

Live bacterial cultures such as probiotics and other microbially active substances are mixed into spray-dried or agglomerated carriers in a particularly gentle manner without losing their instant properties. Even temperature-sensitive vitamins, vital substances, and micronized tea leaves can be mixed homogeneously in the amixon® mixer without thermal or mechanical stress – even in large batches of up to 12 m³. amixon® mixers meet the highest hygiene standards.

Instant drinks such as coffee, tea, vitamin tablets, or vitamin juices......

The same applies to all these products as to baby food and dietary supplements.

Other common applications include

- Homogenize large batches of bulk goods (up to 100m³) with ideal precision

- steaming and sterilizing grain

- refining breading flour

- producing whipped masses with thickening and emulsifying agents

- conditioning seed mixtures

- preparing milk powder, sweeteners

- muesli and cereals

- starch processing

- fermentation processes

- distribution of flow aid

- preparation of cellulose and more

Food grade mixer models

amixon® cone mixer

The AM single-shaft cone mixer from amixon® is one of the most versatile mixing systems for the food industry. From dry powders to wet suspensions, and even pastes and doughs: the screw-shaped mixing tool mixes different food ingredients quickly and expertly.

The conical AM mixer agglomerates, disperses, coats, and homogenizes. It also performs a wide range of functions in food processing and ensures fast and almost complete emptying of 99.997%.

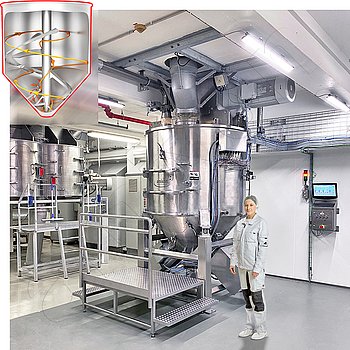

Gyraton® silo blending machine

The Gyraton® is a vertical mixing silo for large quantities of powder up to 100 m³. It is space-saving and compact. It combines a storage container and high-performance mixer in one device. The central mixing spiral conveys the bulk material upwards in a spiral. Gravity causes the bulk material to flow downwards. This results in a slow but extremely efficient overall product turnover. The mixing process requires very little drive power, even with large volumes. For example, a mixing silo with a volume of 50 m³ requires a 30 kW motor.

The Gyraton® mixer operates particularly gently. It achieves ideal mixing qualities even with component compositions of 1 to 100,000, and the mixing quality variation coefficient is less than 5%.

The particle structure is retained and the particle sizes are not changed. The design is dead space-free, hygienic, and easy to clean. On request, the apparatus can be equipped with automatic dry or wet cleaning systems.

Food homogenizer

The KoneSlid® precision food homogenizer gently yet thoroughly mixes fragile and powdery ingredients in as little as 20 to 30 rotations. Equipped with an inverted conical bottom, the KS precision mixer creates a multidimensional flow and discharges food ingredients virtually without segregation.

The KS food homogenizer is exceptionally well-suited for challenging sanitary mixing applications, such as infant formula, baby food, milk powder, muesli, and instant beverages.