Gyraton® blending silo for 50 m³ batches.

Mixing silo achieves optimum mixing qualities

amixon® production only deals with its own patents and developments on the subject of "MIXING". These include

- Precision mixer

- Vacuum contact dryer

- Synthesis reactors

- Apparatus for body agglomeration

and

- Gyraton® mixing silo

We refer to the precision mixing of dispersed solids when, at a component concentration of up to 1:100,000, the coefficient of variation of the mixing quality is reproducibly less than 5%.

The powdery goods to be mixed can be dry, moist or suspended. amixon® is synonymous with vertically operating precision mixers.

.

A Gyraton® silo mixer achieves similar mixing qualities to a classic precision mixer

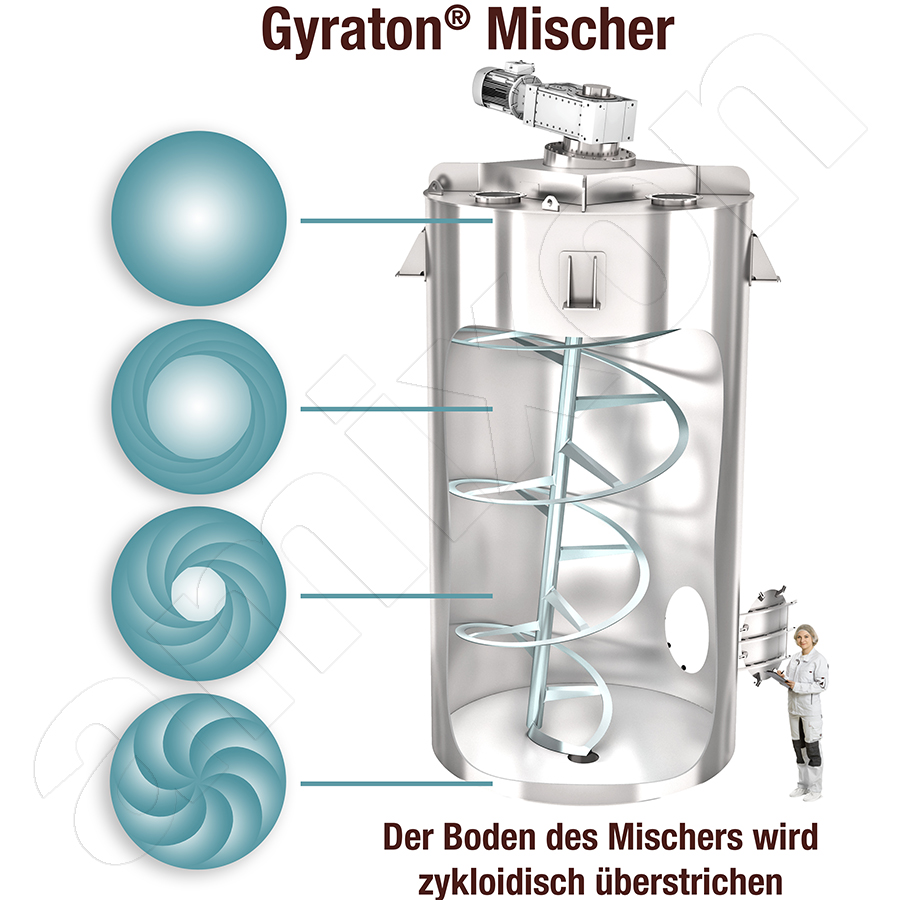

A Gyraton® silo mixer can homogenise up to 100 m³ of mix. In this respect, it is a mixing silo. The special feature: This silo mixer can precisely homogenise large quantities of bulk material with extremely low drive power. The result is mixing qualities that correspond to an ideal random mix.

An ideal random mixture exists when the powder distribution is so homogeneous that optimisation by technical means is no longer possible.

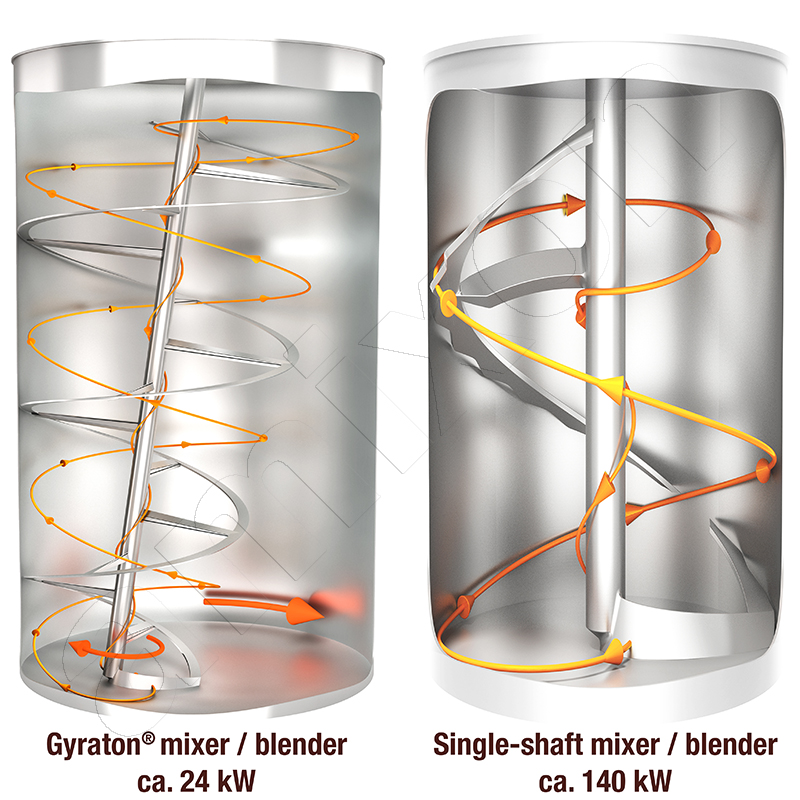

The picture on the right shows a vertical spiral mixer, which is a classic precision mixer. This type of mixer is rarely manufactured larger than 15 m³. Large precision mixers require correspondingly large drive motors and are therefore relatively expensive. Precision mixers cannot be operated as slowly as required.

If the rotation frequency falls below the critical value, the bulk material is only entrained rotationally. As the three-dimensional flow required for a homogeneous mixture does not occur, an ideal random mixture cannot be achieved.

The minimum rotation frequency of a vertical single-shaft mixer is usually around 8 to 12 rpm, but can also be higher. It is largely dependent on the size of the mixer and the rheological properties of the powders, in particular their bulk density, particle size distribution and flowability.

The helical mixing tool of the Gyraton® mixer is mounted on a gimbal at the top. The bottom of the mixing chamber is designed as a spherical shell. Its radius corresponds to the length of the mixing shaft. The superimposition of precession and rotation creates a cycloidal motion. Different circulation profiles result depending on the ratio of precession and rotation frequency. These are adapted to the respective mixing task. Since the centre of rotation continuously shifts, all areas of the mixing chamber are mixed efficiently.

It can be assumed that a Gyraton® mixing tool can be operated at very low rotational frequencies and still produce ideal mixing qualities. This is to be proven.

The mixing efficiency of the Gyraton® mixer is to be proven

amixon® has built a Gyraton® mixing silo with a batch size of 3 m³ for testing. This mixing silo is used to mix different powder batches.

- Very fine inorganic substances such as kaolin and colour pigments are mixed in it.

- Calcium carbonate dust is moistened and mixed with colour pigments.

- Heterogeneous moist powder mixtures are coloured.

- The filling level is maximised for each attempt. The batch size is always 3 m³.

- The small pigment additives are always added last in the centre of the mixing chamber. This is the zone in which the precession movement of the mixing helix is least pronounced.

- In this respect, there is maximum possible segregation at the start of a mixing process!

The circumferential speed of the conical mixing spiral increases from bottom to top. At the same time, the effect of the precession movement decreases from bottom to top.

Proof of excellent mixing quality

All the results obtained are excellent. We then carry out further mixture quality tests under scientific supervision. We use an officially certified proof of quality for animal feed (for livestock). It enables us to prove the homogeneity of component compositions up to a ratio of 1:100,000.

We fill exactly 1,500 kg of finely ground animal feed for pigs and cattle. The substance patent blue is used as a tracer. Patent blue is extremely colour-intensive, water-soluble and finely dispersed and is present in a deagglomerated and dry form. We add exactly 15 grams of it from above into the centre of the mixing chamber. The result is a substance composition with a weight ratio of 1:100,000.

We then close the mixing chamber and start the mixing tool.

Lambert's formula.

Lambert's law

After a precisely defined number of revolutions, the mixing tool is stopped. Samples of 30 grams each are taken from ten different points in the mixing chamber and packed tightly in small bags. In the laboratory, exactly 15,000 mg of these are taken, filled into a standardised cuvette and then a precisely defined quantity of ultrapure water is added.

After the standardised solution time has elapsed, a homogeneous colour solution is present. A monochromatic light source shines through the cuvette. The measurement is based on Lambert's law, which describes the relationship between light absorption and the concentration of the dissolved substance. A photodetector records the intensity of the transmitted light. A cuvette filled with 15 grams of dye-free mixture serves as a reference. The measured light absorption is proportional to the dye concentration in the sample.

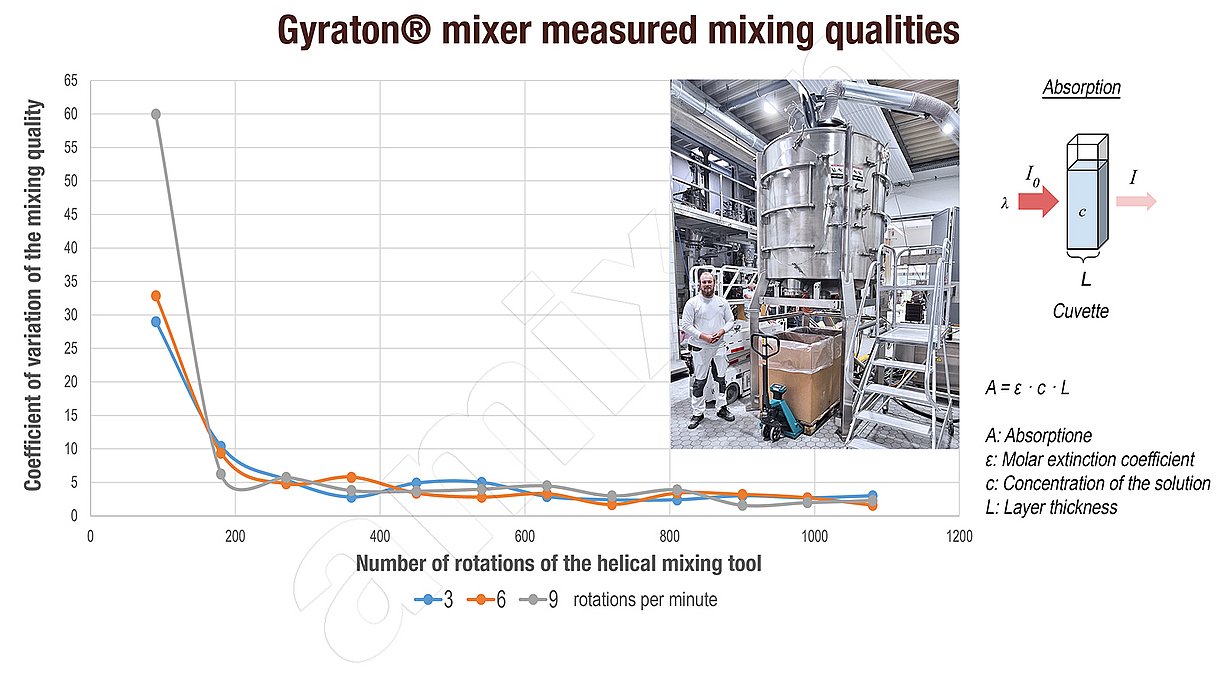

The results are impressive. The Gyraton® mixer always produces consistent mixing qualities. This applies regardless of the rotation speed of the Helix mixing tool. Only the number of revolutions is decisive.

Obviously, we have a mixing system here that can be scaled for large batches. Ideal mixing qualities can be achieved with very small drive motors.

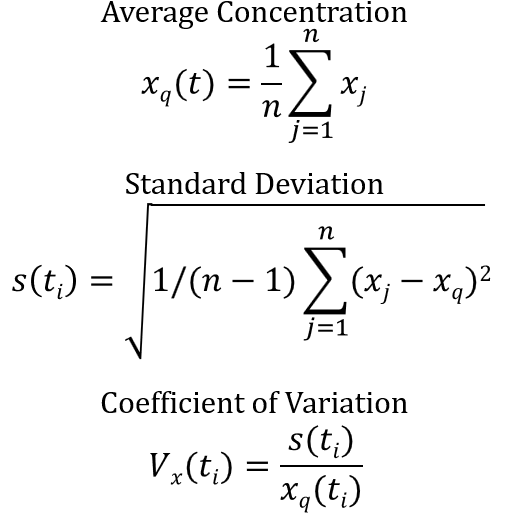

Achievable mixing quality – a consideration using the coefficient of variation

Mixing quality is usually described by the coefficient of variation. Of particular interest is how this characteristic value changes over the course of a defined mixing process and at what point it reaches a stable, optimal value. In practice, the stable final value corresponds to the maximum achievable random mixture. This is not perfect, but shows a so-called residual dispersion, V∞. This describes the remaining deviation from an ideal uniform distribution in the statistical mean.

The temporal course of the coefficient of variation can be ideally represented by an exponential function.

Vx(t) = V0 · e−k·t + V∞

x1,x2,...,xn : Concentration levels

n : Number of samples

s : Standard deviation

xq : Middel value of the concentration

V0 : Coefficient of variation of the initial dispersion

Vx : Coefficient of variation

k : mixing intensity

t : mixing time

V∞ : coefficient of variation of the residual dispersion in equilibrium

Note:

In order to achieve even better homogeneity than the mixing quality that can be achieved by chance, each individual particle of all components would theoretically have to be placed in exactly the right place in a three-dimensional matrix. This is conceivable – but not feasible in practice.

Mixing quality curve

Great flexibility and versatility

In order to be able to better categorise the mixing quality results, we compare them with those of our established precision mixers. We have many reference results available for this purpose. We can prove that the Gyraton mixer produces ideal mixing qualities under the operating conditions we have selected.

It seems to be valid in many areas that the rotational frequency of the Gyraton mixing tool multiplied by its mixing time results in a constant:

Rotation frequency - mixing time = constant C1

It is known from many years of practical experience that the drive torque of vertical spiral mixers remains largely constant as long as "push mixing" takes place. In this respect, the product of drive power and mixing time is also constant

Drive power - mixing time = constant C2

The graph on the left shows the flexibility. If there is no rush, the Gyraton® mixer can be operated with the solar energy currently available from the roof, for example. At the end, a large powder batch is ideally homogenised.

As a rule, no high demands are placed on the mixing time of a silo mixer anyway. The storage time is available for homogenisation. So if there is no rush, the Gyraton® mixer can be operated with the solar energy currently available from the roof, for example. In the end, a large batch of powder is homogenised with ideal precision.

Let's assume that a 40-foot sea container is delivered to the port of Hamburg. It is filled with ground rare earth ore. The question then arises as to the actual content of rare earths. A 40-foot sea container has a volume of approximately 70 cubic metres.

A Gyraton® mixer with a useful capacity of 70 m³ can provide a valuable service here, as it homogenises the product at a low cost. It takes half a day or a whole day to do this, for example. A product sample is then taken and analysed in the mixing room. After the analysis, it is clear how much recyclable material is in this delivery and how the value of the delivery is to be calculated.

In addition, the many downstream processing steps can be much better optimised and controlled.

Outlook and summary

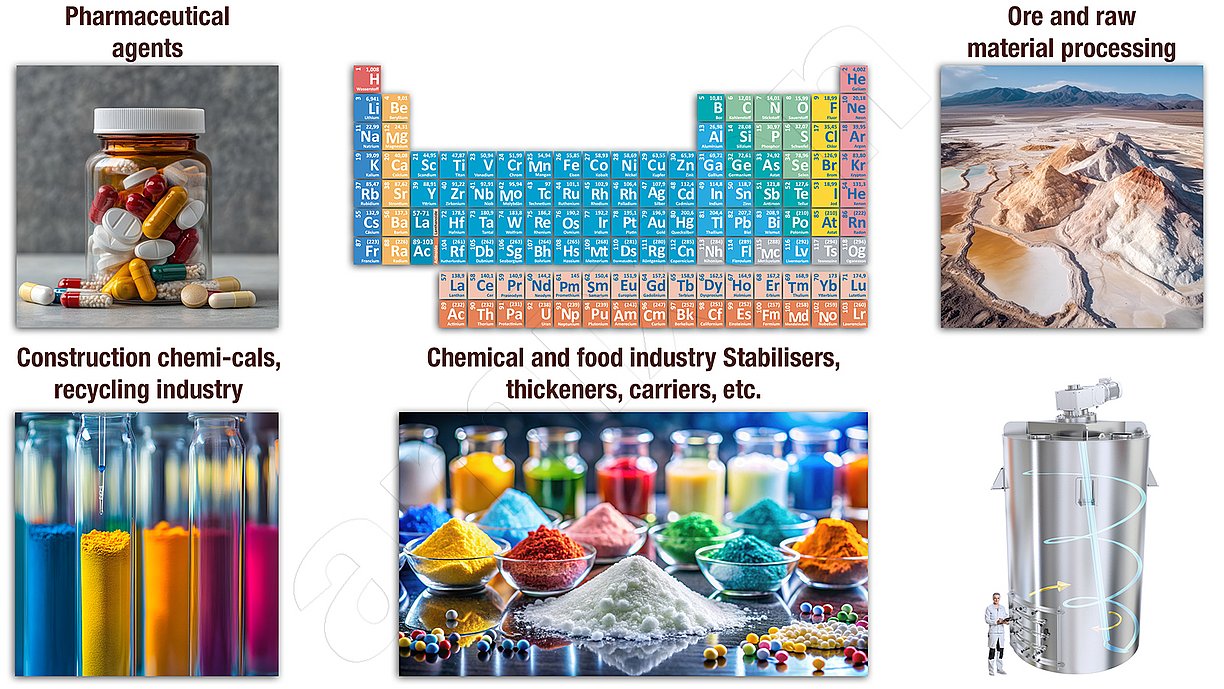

There are good reasons to believe that the Gyraton mixing system offers interesting marketing opportunities.

Large quantities of raw materials are produced wherever basic material processing takes place - especially in the extraction of alkali metals, which also includes lithium extraction.

In good deposits, the lithium enrichment is 0.006 % at most. In order to extract 1 kg of pure lithium, 16.7 tonnes of raw material must be processed.

The process chains are correspondingly long and include comminution, classification, density separation, suspension in digestion acids, chemical extraction, precipitation, flocculation, sedimentation, filtration, drying, calcination, grinding....

This is always followed by homogenisation. It is the start of the next process stage. The more homogeneous the starting materials are, the more efficiently the next process can be controlled and the higher the yields. This also applies in a similar way to recycling and synthesis chemistry, in which new active ingredients and base materials are created.

Large batches have to be homogenised in the production of active pharmaceutical ingredients (API). Similarly, carriers and functional additives for pharmaceuticals, nutrients, starch derivatives, methyl cellulose, pectin and gelatine must be homogenised in large volumes.

© Copyright by amixon GmbH