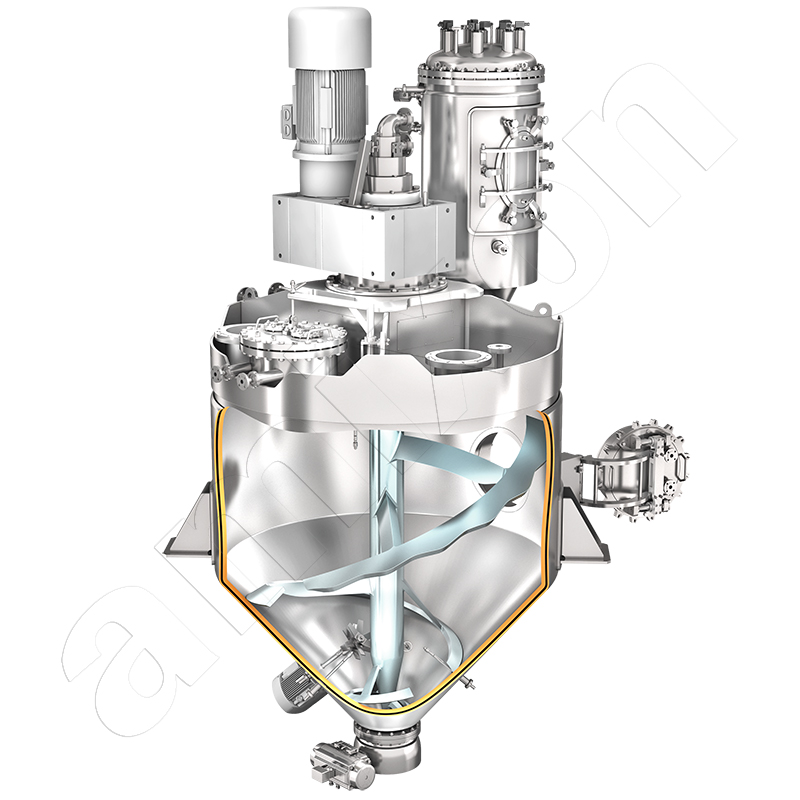

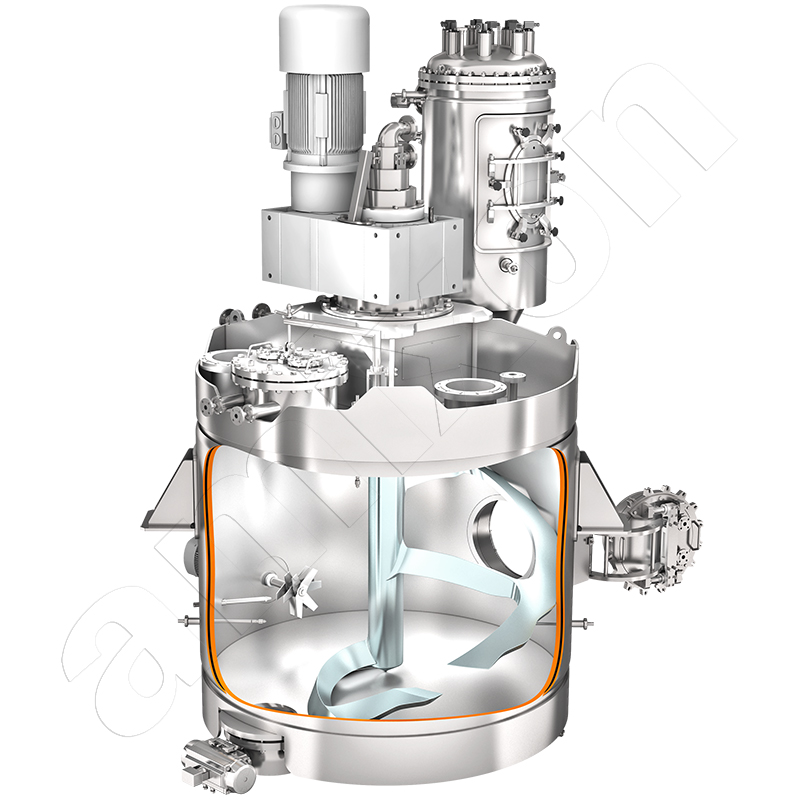

amixon® mixer/ vacuum dryer/ sterile reactor VMT 6000 for 6 m³ batches operates at low tool speed. This preserves the particles in the best possible way.

Sterilization of spices, tea, cocoa, curry mixtures and cereal derivatives in the amixon® vacuum dryer

amixon® vacuum mix dryers/reactors can effectively sterilise natural products.

The health benefits of spices are undisputed. Valuable extracts are obtained from chilli, ginger, turmeric, sage, garlic, onions and cinnamon. They are even referred to as functional foods because experience shows that they can actually help to prevent diseases. However, this does not mean that they have healing properties.

The industrial use of spices, herbs and nutrients usually requires that the substances are ground beforehand. Before milling, it must be ensured that spices, tea, cocoa and cereals are clean, i.e. free of foreign particles. The term cleanliness is microbiological hygiene is also meant in particular.

Natural products can be contaminated with unwanted germs. These micro-organisms must be inactivated by thermal-pneumatic effects. Heating, moistening, drying and cooling are carried out in the amixon® sterile reactor. Treatment in the amixon® reduces the germ count by several orders of magnitude. Optionally, the germ count can be reduced to 0.

It is impossible to avoid mold spores 100%.

Microorganisms must only be present to a very low degree. Spices sold to the end consumer must be low in germs. Spices sold to the food industry must be even much lower in germs. Convenience products should have a long shelf life and taste good.

Even if the vocabulary "steam sterilization" is used here, it is definitely not sterilization in the medical sense. Agricultural products cannot be sterile at all. It is only a reduction of unwanted microbes and germs.

Sterile steam is injected into the product during mixing

An effective method for germ reduction is the incorporation of hot water vapor. The spices, tea, cocoa, cereals are placed in a pressure-resistant, heated mixing chamber. They are mixed gently and slowly. First, the mixing chamber is under vacuum, then sterilized steam is injected at several points at the same time. A gauge pressure is built up in the mixing chamber.

The thermal energy of the water steam is released by condensation on the surface of the particles. Water has an extremely high enthalpy of evaporation. At the moment of condensation, a big amount of thermal energy is transferred to the spices very fast. The surface of the particles heats up and the germs on the surface are killed.

amixon® - sterile mixers facilitate success in a special way:

- The heating of all machine parts in contact with the product ensures that the water vapor only condenses on the spice.

- The gentle way of mixing ensures that the particle structure is preserved

When the disinfection target has been reached, the moisture introduced must be removed from the spice. Then the spice must be cooled. Both are done at the same time by vacuuming of the mixing chamber. In general, the germ contamination is reduced by several magnitudes of ten.

Why is this process not used for all types of spices?

Comment from a customer: I think that an amixon® mixer/dryer/reactor is well suited, partly because it is easy to clean. In this regard, I ask myself the question, "Why is this process not used for all types of spices?"

Answer from amixon®:

The sterilization method itself really does work very well. Microorganisms, especially mold spores, can be killed effectively with this method of "steam sterilization". Unfortunately, this process cannot be applied in the same way to all types of spices, as more or less important proportions of essential oils and thus of precious aromas could be lost.

However, this "sterilization" method does work extremely well with certain pure spices and spice blends such as curry spice compounds. Depending on the type and particle size of the respective spice, the batch size, temperature level, mechanical agitation, quantity and temperature of the injected steam, timing, duration of mixing and control of the vacuum must be matched to one another. The above parameters can only be optimized by means of tests.

You can see the sequence of a process in our blog article "Deactivation of enzymes".

We can refine your powders in the pilot plant

Question from a customer: Is it possible to test whether the method described above is effective for our herbs, curry blends, cocoa and powders?

Answer from amixon®:

Yes, amixon® offers you the possibility to conduct tests. The testing of the "sterilization process" as described above is unavoidable. We recommend that you bring original products with you. You are welcome to anonymize both the products and the associated safety data sheets. The amixon® test center enables you to perform mixing and sterilization tests with various process parameters. The quality of the processed end product (perhaps an instant food) determines the suitability of this sterilization method.

A visit to amixon is always informative

We cordially invite you to visit us. The amixon® technical centre is superbly equipped and is sure to provide you with valuable insights into mixing, sterilisation, vacuum mix-drying and synthesis reactions.

Our factory tour will show you the highlights of hygienic apparatus construction.

© Copyright by amixon GmbH