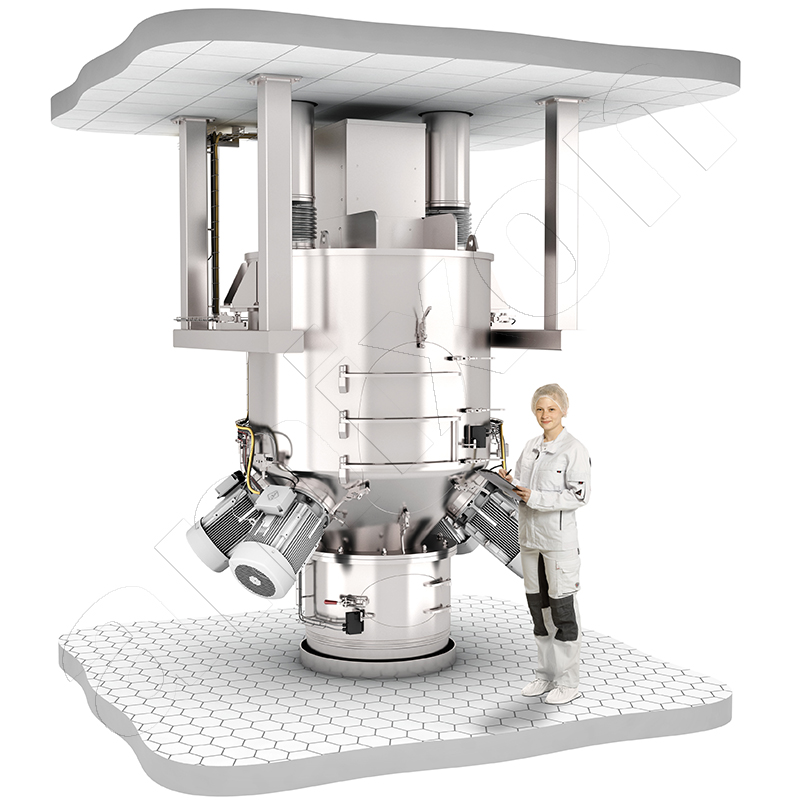

Powder mixers for Instant soups, instant meals

Mixing task and advantages of working with the single shaft mixer type KS

Basic ingredients such as agglomerated milk powder, baby food, cereal derivatives, dextrose, starch, salt, egg powder, cheese powder, glutamate, flavourings, oils, extracts, fats, etc. must be homogeneously distributed and protected against separation.

The ingredients must be homogeneously distributed and protected against separation. The recipe contains fragile components such as garnishing spices, agglomerates, dried fruit, vegetables and freeze-dried herbs. This creates the perfect instant ready meal.

Advantages of the KoneSlid® mixer

The mixture is

- ideally homogeneous

- the mixing time is extremely short

- the mixing tool rotation frequency is very slow

- Products are dust-free, free-flowing

- Particles are not damaged

- no temperature changes

- little sticking

- Coarse pieces and fruit appear natural, fresh, without damage

- Mixing and discharge can take place in a protective gas atmosphere.

- Product discharge in seconds

- KoneSlid® mixers can discharge up to 99.99%.

The mixture is

- ideally homogeneous

- the mixing time is extremely short

- the mixing tool rotation frequency is very slow

- Products are dust-free, free-flowing

- Particles are not damaged

- no temperature changes

- little sticking

- Coarse pieces and fruit appear natural, fresh, without damage

- Mixing and discharge can take place in a protective gas atmosphere.

- Product discharge in seconds

- KoneSlid® mixers can discharge up to 99.99%.

Cutting rotors, HighShearBlades, choppers, whirlers, knife mills, knife heads, mixing accelerators

The KoneSlid® mixer can homogenise gently. However, the same mixer can also deagglomerate intensively with a high energy input. It is equipped with cutting rotors for this purpose. These rotate at high speed. They shear, rub, compact, deagglomerate and de-clump the powder particles. They can accelerate wetting if liquid components are involved.

The KoneSlid® mixer can homogenise gently. However, the same mixer can also deagglomerate intensively with a high energy input. It is equipped with cutting rotors for this purpose. These rotate at high speed. They shear, rub, compact, deagglomerate and de-clump the powder particles. They can accelerate wetting if liquid components are involved.

© Copyright by amixon GmbH