Stabilizers help to preserve the chemical-physical properties of an instant product, a beverage, (vegan) fast food, bakery goods or meat products, over longer periods of time.

Food stabilizers are functional ingredients

The term "food stabilizer" is a generic description for a large number of different substances and compositions of substances. The composition of a food stabilizer may include gelatin, pectins, sugar substitutes, modified starch, methyl cellulose, phosphates, plant fibers, preservatives, malt extracts, antioxidants, emulsifiers, hydrocolloids, enzymes, and more.

Stabilizers in the food industry are usually powdery, dry-appearing blended products. For handling reasons, they should be low in dust and free-flowing. The stabilizers should remain lump-free and free-flowing even after prolonged storage (e.g. on stacked pallets). Sometimes the powdery stabilizer mixtures contain many and, if necessary, particularly small components. These can also be small liquid components.

It is not trivial to incorporate these dry or liquid minor components into the base powders in a microfine way. The production of food stabilizers requires a great amount of care, because in fact only those substances may be contained that are declared in the list of ingredients. Any possible residual substances carried over from other mixes must not be included. Although food stabilizers are also needed in liquid form, the powder form is preferred. In powder form, their shelf life is far more durable than in liquid form.

If the stabilizer should be used in liquid form, it must first be dispersed or dissolved in a suitable liquid by means of "high-shear liquid homogenization". This process engineering step can be challenging if the stabilizer has a high air-holding capacity and foams up in the liquid. For this reason, some stabilizers are available in agglomerated quality with good instant properties.

Stabilizers are used in almost all nutrient factories

Stabilizers help to preserve the chemical-physical properties of an instant product, a beverage, (vegan) fast food, bakery goods or meat products, over longer periods of time. Examples include: Maintaining a mixed state of a liquid composed of immiscible phases such as water and fat. Maintaining a floating state when finely dispersed solids or coagulates need to be permanently homogeneously distributed in a liquid.

Stabilizers serve

- the preservation or intensification of a coloration for longer periods of time

- the preservation of the structure of frozen goods after thawing

- the control of the melting behavior of ice cream, for example adjusted to changing ambient temperatures

- the production and maintenance of a jelly (coagulation)

- the solidification behavior of cake layers

- the viscosity of sauces and dressings

- the consistency of meat sausages

- the consistency of vegan meat substitutes

- in many other applications .......

The mixer can fill mixing goods directly into BigBags

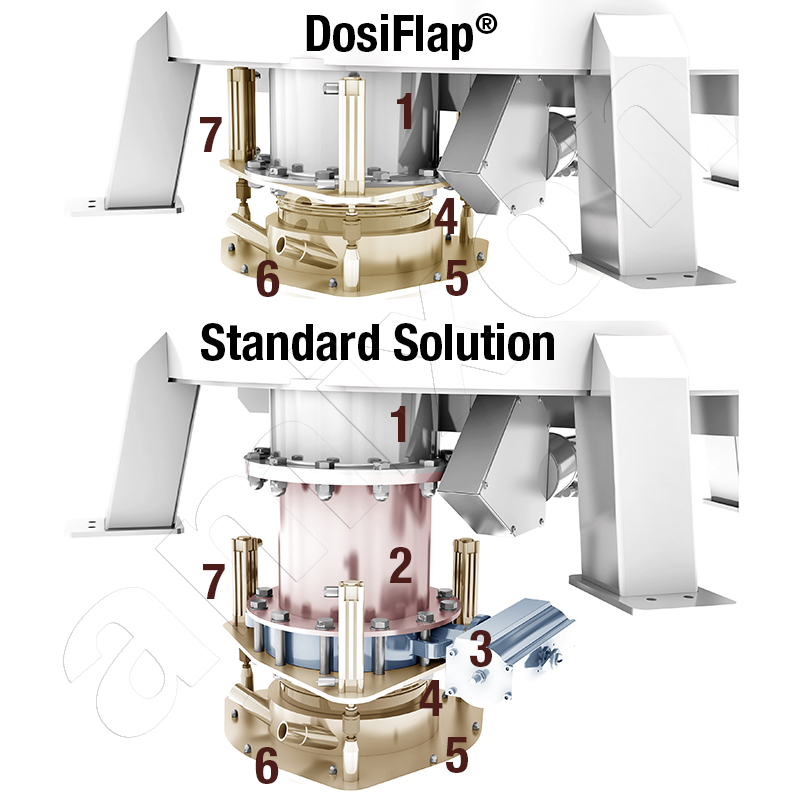

Food stabilizers are preferably offered in powder form. They are usually a powdery mixed product packed in cans, bags, sacks or BigBags. Filling of the big bags can be done directly from the mixer. In this case, amixon® offers an interesting concept. DosiFlap® functions equally as a dead space-free closing valve and as a metering device and saves a lot of vertical installation space.

Read more about DosiFlap®!

Weighing of the mixer and mixer contents

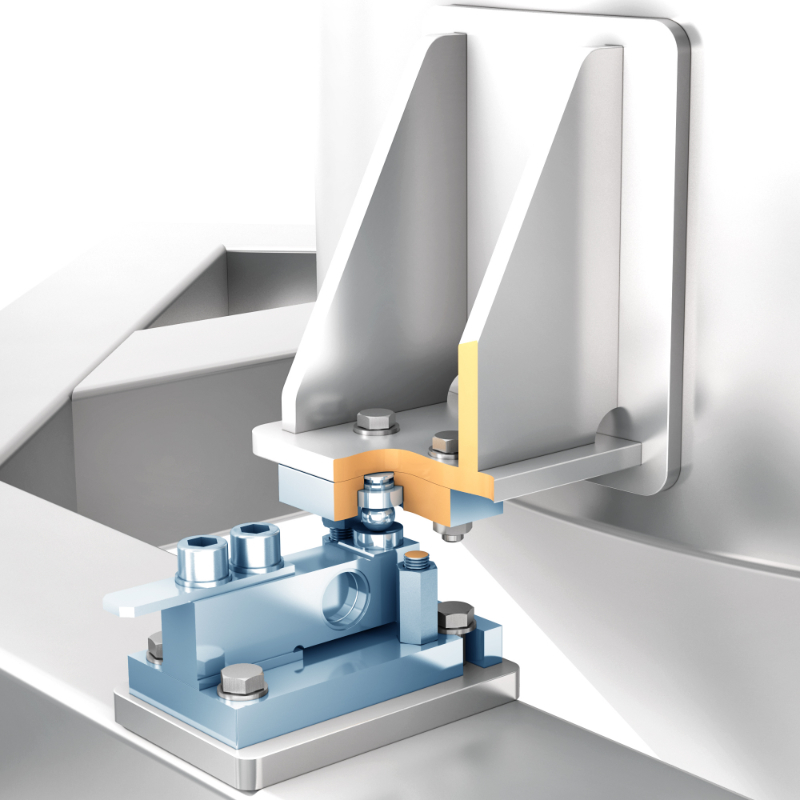

If bulk containers or BigBags are filled directly from the mixer discharge opening, it is important that their maximum filling levels are not exceeded. In addition, the operator would like to know the weight content of the containers. In this context, it is interesting to ask how precisely this data can be determined on the basis of the mixer weighing equipment. amixon® has written a short blog article on this subject that may be of interest to you: "Mixers installed on load cells ".

© Copyright by amixon GmbH