Excursus: Bulk containers (IBCs) help to automate powder mixing operations.

This article explains the logistics of a powder mixing system using standard bulk containers. There are also container mixing systems in which the bulk goods container itself forms the mixing chamber. This topic will be covered in another blog post.

Many everyday goods have a long production process behind them. Often, powdery substances were also involved. In many cases, these are mixtures of different powders and liquids. Before such a mixing process can take place, numerous preparations must be made: The raw materials are fed into the system from outside. They are subjected to quality control, sieved, classified and stored in silos, big bags or the plant's own bulk material containers. Further processing steps are optional, such as Classifying, crushing, agglomerating, drying, ....

What are the arguments in favour of using bulk containers in a powder mixing plant?

A container-based powder mixing system allows you to work very flexibly. The work steps:

- Component weighing

- Feeding

- Mixing

- Sampling and analysis

- Post-processing

- Filling

are decoupled from each other in terms of time and space. The areas can even be automated in different ways. In each area, production, cleaning, drying, inspection, repair and .... can be carried out largely independently of the other areas.

Important requirements are

- A sufficient number of bulk containers must be available.

- There must be sufficient space for the bulk containers.

- Forklift trucks or driverless transport systems must be available.

- Sufficient traffic area must be available.

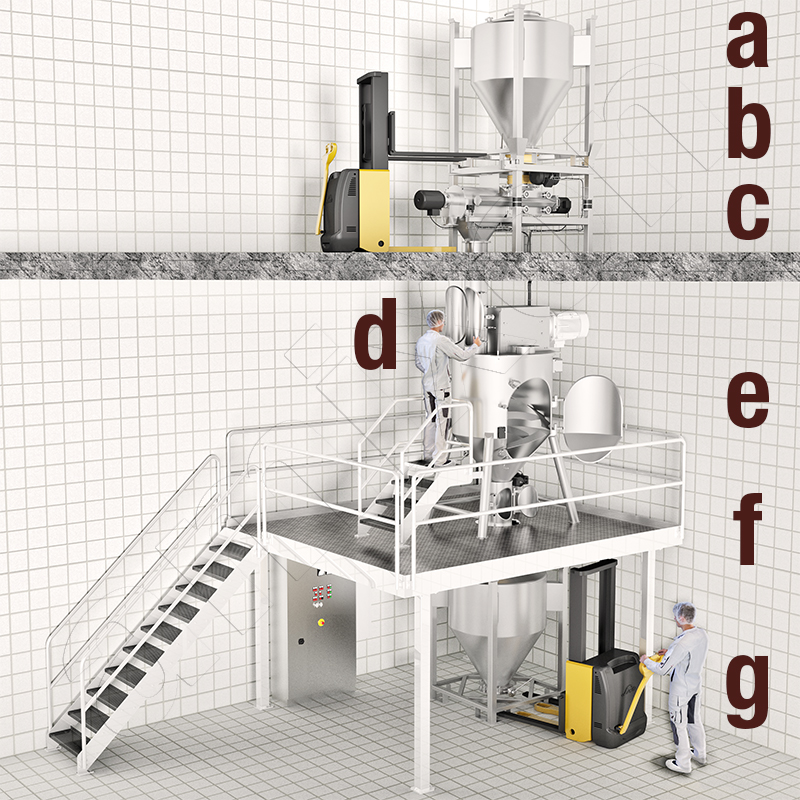

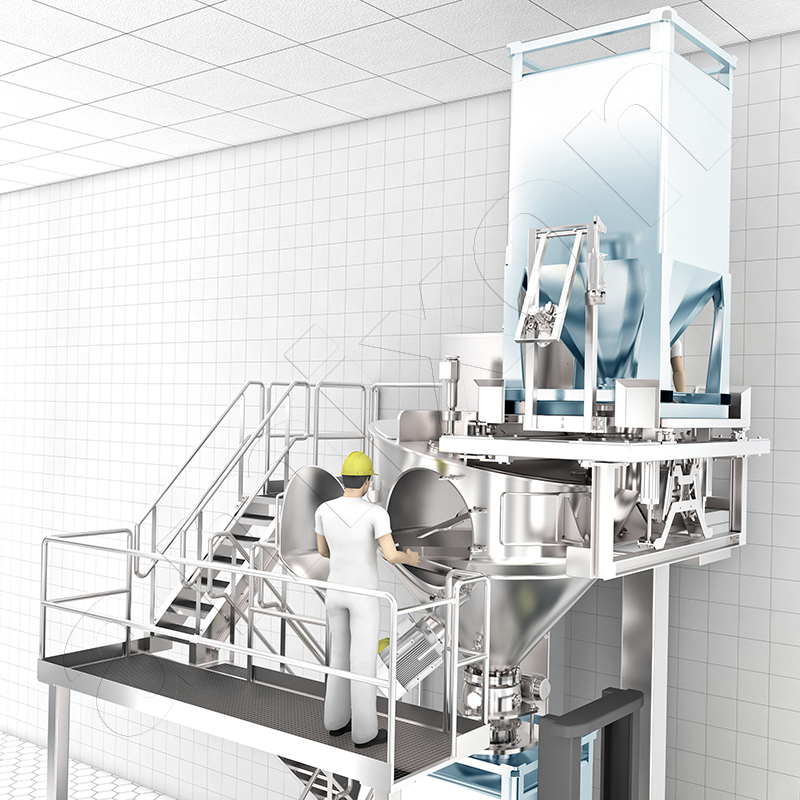

The mixing system shown above requires comparatively little space. However, the mixed goods must be sufficiently free-flowing to be emptied from the container. This is done with the help of container docking systems. These dock dust-tight underneath the discharge fitting. Optionally, the material flow can be stimulated by vibration excitation. On request, the container can be weighed before and after emptying.

Three operating levels allow ergonomic and convenient access to the mixing system.

This mixing system works with standard bulk containers. The same IBCs can be used for filling and emptying the conical mixer.

The support structure has four service levels for the operator. All inspections can be carried out ergonomically:

- on the filter on top of the mixer.

- at the container docking station for loading.

- in the mixing room.

- at the container docking station for emptying.

- all measures for wet cleaning and drying.

Remark:

amixon® Cone mixers, which are fed and emptied by means of bulk material containers (IBC), can also be used when the available room height is limited. available room height is limited. is limited.

Flexibility: The filling level of an amixon® conical mixer can vary greatly.

There is a more detailed blog post on the topic of different filling levels in the amixon® conical mixer blog post. In addition, the conical mixer has excellent properties with regard to complete emptying. This applies to almost all free-flowing powders. The large inspection doors are hygienically designed and sealed with OmgaSeal®. Manual dry cleaning is completed in just a few minutes.

Visit the amixon® technical centre

for carrying out mixing tests. You are welcome to bring your most difficult products with you. The tests are carried out on a 400-litre, 2000-litre or 3000-litre scale. We predict the best results for you. The amixon® experts will provide you with many valuable insights during the trials.

https://www.youtube.com/watch?v=ER3yvdN3tOY

SEQUENCE versus LINE in the processing of bulk materials

The tradition of bulk material processing technology can be traced back to grain mills. Traditionally, the grain raw materials were conveyed upwards. Grinding and processing took place in stages. Flour, meal and residues were collected at the bottom and filled into sacks.

This type of fabric finishing is widely used. The bulk material is fed through the individual machines from top to bottom with the help of gravity. The substances can flow through branches, returns and deflections. The processing machines are usually permanently piped together. The goods flow through pipelines in a linear fashion.

Sequential preparation: In some cases, there are good reasons for decoupling the individual process steps from one another. This is possible if the internal bulk goods logistics are organised with large containers (IBCs) or BigBags. If the individual process steps run at different speeds or are automated differently, they can still be combined well in decoupled operation. Intermediate bulk containers (IBCs) or big bags serve as hygienic interim storage and transport systems. Additional work such as inspection, cleaning, drying, maintenance and repair can also be carried out independently. Important requirements are that a sufficient number of containers / big bags are available and that the necessary storage space is available.

© Copyright by amixon GmbH