All-rounder for small and large batches. The AM 1500 conical powder mixer.

FAQ: All-rounder for small and large batches and ideal mixing qualities?

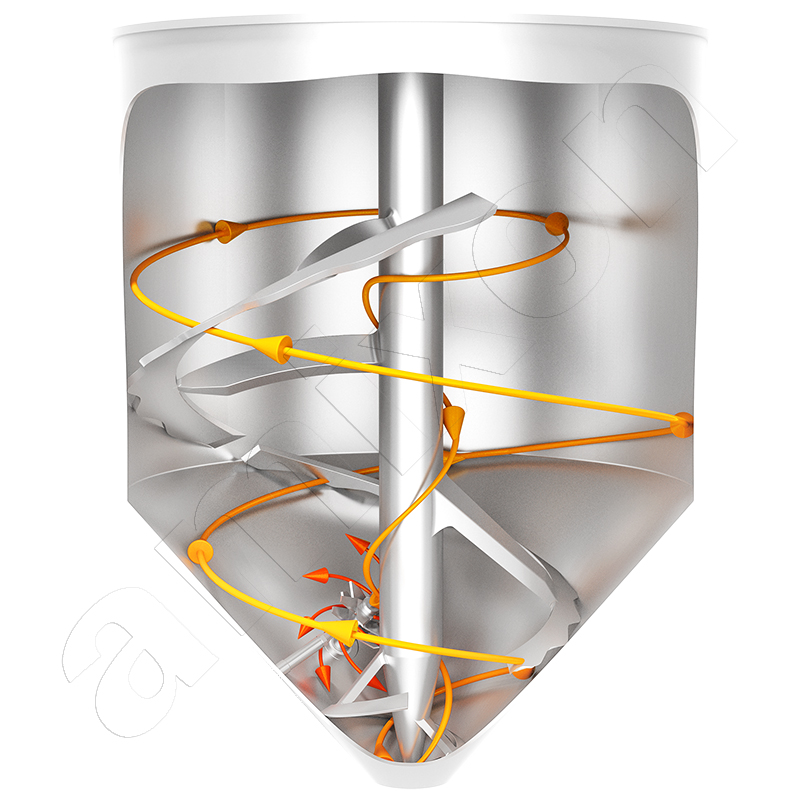

An all-rounder for small and large batches and ideal mixing qualities. Hundreds of mixing companies with over 1,000 recipes have confirmed that this conical mixer mixes quickly and with ideal precision. The mixing result is always optimal, regardless of the powder properties: different particle sizes, different bulk densities, finely dispersed, coarse, wet, clumped, moist, dry, fluidising, free-flowing or adhering .... etc.

How can this great flexibility / variety of applications be explained? Here you will find answers to frequently asked questions.

If you want to mix/ homogenise/ blend particularly large batches/ powder quantities, amixon has another solution for you. Take a look at our Gyraton® mixer. It can blend particularly large bulk material masses extremely gently.

Sometimes the operator wants to mix not only large but also very small batches with one and the same mixer. Then, for example, the filling level is only 10 %. But the mixing quality should be ideally good. Which type of powder mixer is recommended then?

"Highest mixing quality with different filling levels"! This is a difficult mixing task. It requires the use of vertical mixers. Among vertical mixers, conical mixers are the most suitable. Hardly any other type of mixer can be used for filling levels as low as 5 % or 10 %. The amixon® conical mixer is characterised by maximum flexibility.

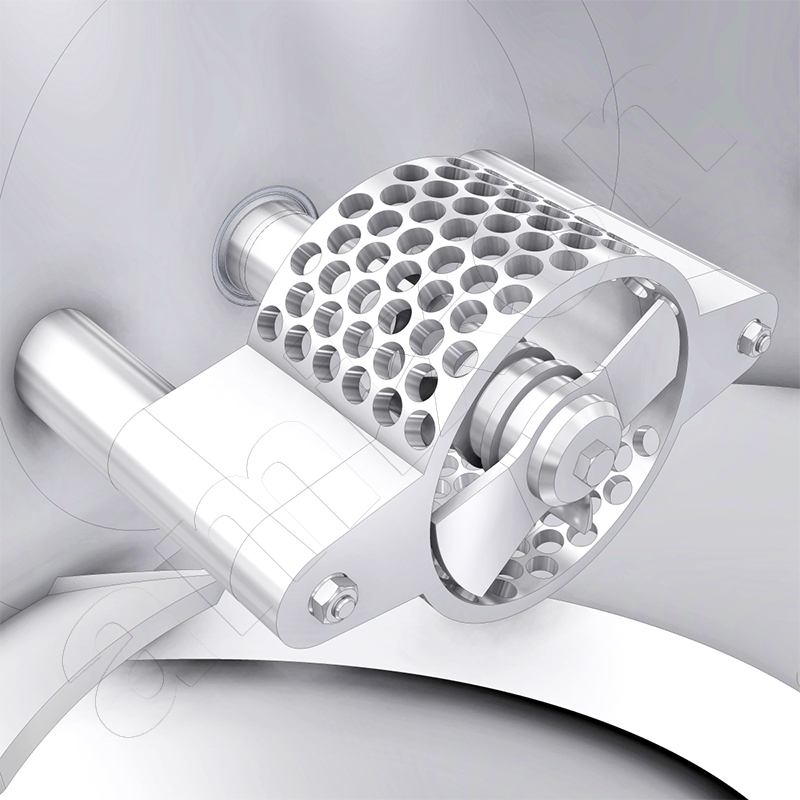

Most of our mixing jobs include the requirement to use a chopper to ensure that any lumps or agglomerates present are deagglomerated.

This raises two questions:

- Is the application range of the conical mixer limited at low filling levels if agglomerates and lumps have to be crushed?

- Is the application range of the conical mixer limited at a low filling level if highly viscous liquids are to be distributed into powder?

The size reduction of lumps and agglomerates is of crucial importance. Only when all particles are separated/deagglomerated can they be optimally distributed. This is why fast-rotating choppers support the mixing process.

Such choppers have different names. For example, whirlers, choppers, cutter heads, cutting rotors, high-shear blades, homogenisers or mixing accelerators. Choppers can also be designed as rotor-stator machines. They then work in a similar way to a mill.

It is interesting to note, however, that deagglomeration in the conical mixer is effective even at low filling levels. Good efficiency is always achieved when the agitator is covered by the powder. Conical mixers can fulfil this requirement particularly well.

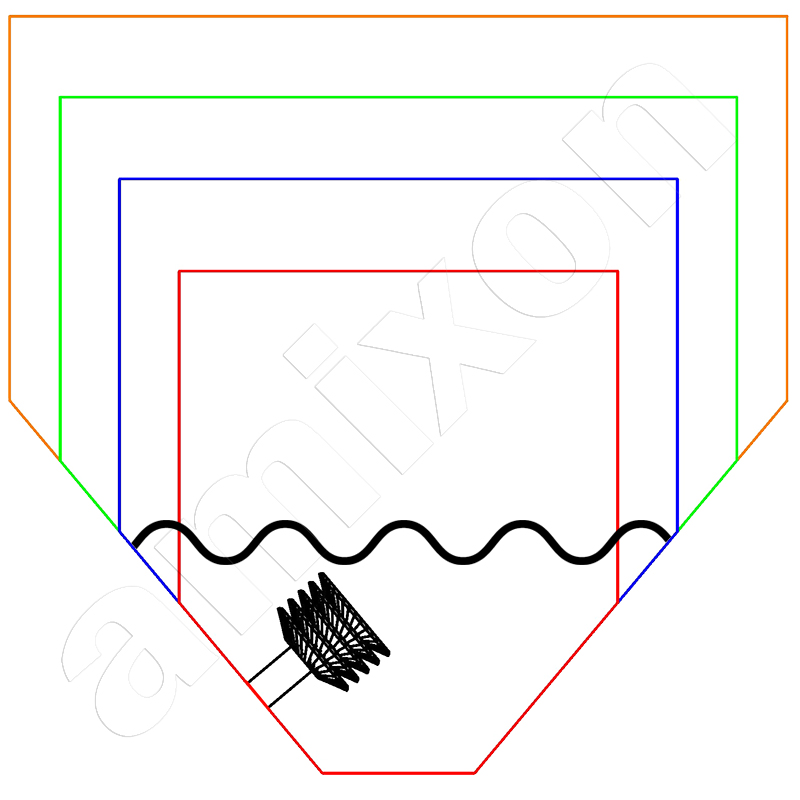

The minimum fill level is an almost constant value.

Four conical mixers of different sizes are shown in simplified form. The smallest is shown in red, the largest in yellow. What they all have in common is the constant position of the chopper. It can therefore be seen that the minimum fill level remains the same, even if the conical mixer itself is chosen to be larger.

The flexibility of the batch size for conical mixers increases with the size of the conical mixer.

amixon® recommends: In order to define the minimum fill level of your future mixer, mixing tests should be carried out in the amixon® technical centre. These tests can be used to answer 4 important questions:

- Which type of agitator has the best effect?

- Which speed has the best effect?

- What drive power must be installed?

- How many centimetres of powder should be at least above the agitator?

Are there any other reasons to choose a conical mixer from amixon®?

Yes, indeed. There are other valid reasons to choose an amixon® conical mixer.

- excellent discharge of residues when the mixing goods are sufficiently free-flowing.

- excellent accessibility with the aid of one or more hygienically designed inspection doors.

- highest hygienic standards.

- Very easy cleaning; whether dry, wet or damp, manual or automatic.

- particularly stable construction and a long service life

- amixon® mixers are permanently gas-tight. This applies equally to dust and water.

- amixon® provides excellent after sales service worldwide.

If it is claimed that one and the same amixon® mixer can be used for different types of powder, why does it still make sense to arrange mixing trials at amixon®?

Before making a purchase decision, we generally advise mixing trials in our test-centre. The particle size distribution and the appearance, flowability and colouring of the powders are strongly influenced by the agitator design and the operating mode.

In addition, mixing trials with a foreign mixing system are always accompanied by new impulses and perceptions. A visit to amixon® is sure to provide you with a great gain in knowledge.

Minimum filling levels can be defined for various mixer sizes: for gentle homogenisation and for deagglomerating powder preparation.

© Copyright by amixon GmbH