Continuous mixing of powders: Pipe flow versus boiler flow

The industrial mixing and wetting of powdery goods takes place either batchwise or continuously.

In industry, bulk materials are mixed in batches or continuously. Mixing" is used here as a generic term for a variety of accompanying processes such as deagglomeration, crushing, colouring, decaking, coating, liquid wetting, agglomeration, tempering, mixer drying, synthesis reaction, bonding, ... Please also read our blog post: "Continuous mixing versus batch mixing"!

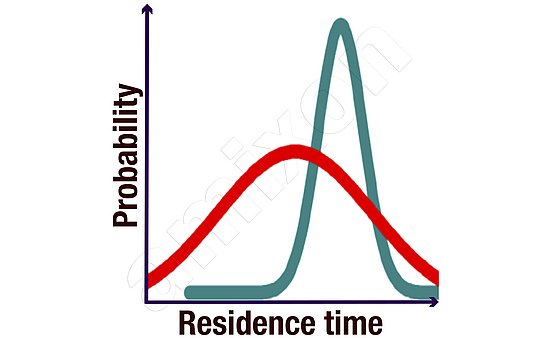

In the case of continuous mixing, a distinction is made between the pipe flow and the boiler flow. In practice, there are also hybride forms of both processes.

© Copyright by amixon GmbH