FAQ – Vacuum drying with amixon® mixing technology

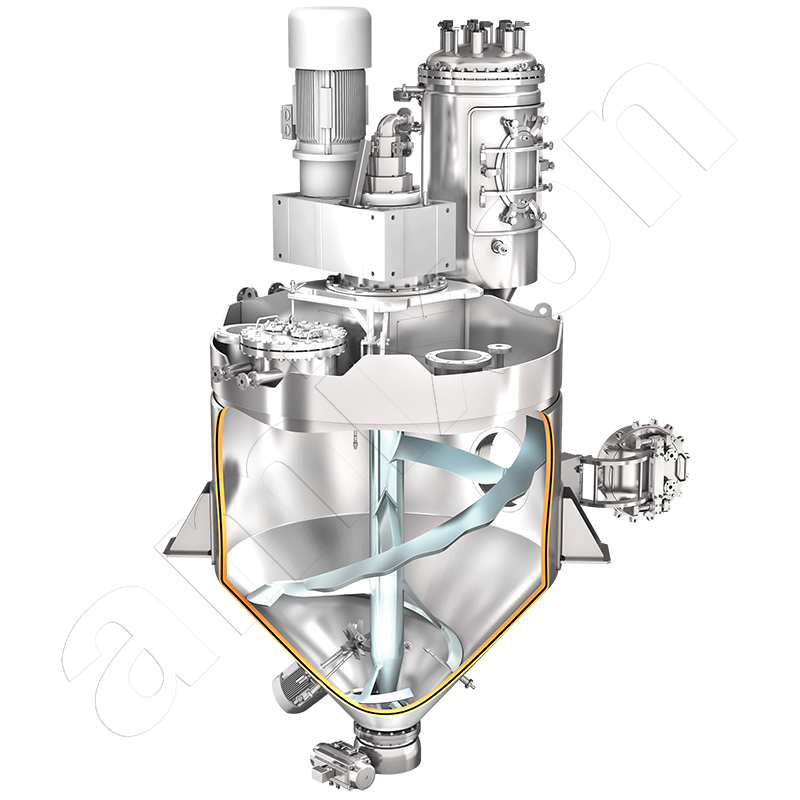

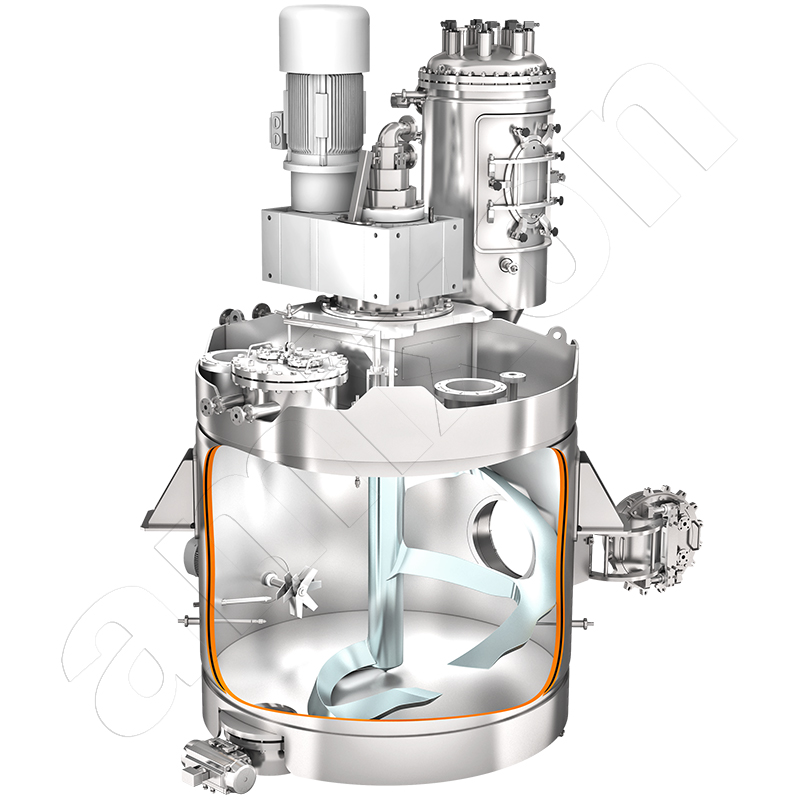

Pressure and vacuum resistant reactors are required when vacuum drying is to be carried out. Then the wet or moist product must also be heated. This is usually done by giving the mixer a double jacket. A heat transfer medium circulates in the double jacket. This is steam, water, thermal oil or a molten salt (at particularly high temperatures). It is often advantageous if the mixing tools are also fully tempered. Either steam, water or thermal oil also circulates in the mixing tools. Basically, two efficient reactor designs are available in vertical construction. Shown on the left, the flat-bottom reactor and on the right the conical reactor.

Heat needed for drying can damage sensitive active ingredients. What does amixon® suggest if the drying temperature should be low?

A drying process can be fast and effective even at low temperatures. One lowers the system pressure by applying a vacuum. amixon® apparatuses are manufactured gas-tight. They can be operated with a vacuum of less than 50 mbar or even less than 5 mbar. If the pressure in the mixer-dryer is only 50 mbar, water will boil at a temperature of 33°C already. If the pressure in the mixer-dryer is only 10 mbar, water boils already at 10°C. Contact drying in the amixon® mixer dryer is a particularly gentle and low-emission drying method. The result is a dry, pure powder.

![[Translate to English:] [Translate to English:]](/fileadmin/amixon/Articles/0012_FAQ_-_Vakuumtrocknung_mit_amixon_R__Mischtechnik/VMT_12000.jpg)

amixon® vacuum mixer dryer/reactor VMT 12 000 (with 12 m³ usable volume). Parts in contact with the product made of Alloy 59.

What role do mixing dryers and synthesis reactors play in food processing and feed production?

Vacuum mixers and synthesis reactors play a lesser role in food and feed production than in chemical synthesis processes (active pharmaceutical ingredients, chemical agents, pesticides, plastic stabilisers, inorganic or organic dyes, starch derivatives, sterile substrates, ...).

Impregnate

Pelletised compound feeds sometimes have to be impregnated with high fat contents. In this case, impregnation can be conveniently carried out by heating and vacuuming the pellets before adding the fat. The capillaries are then free of air and the fat can penetrate. Then the system pressure in the mixer/reactor is slowly increased to ambient pressure. This allows the fat to penetrate into the pores of the compacts.

Are these amixon® mixer-dryers similar in performance to a vacuum paddle dryer in horizontal design?

Yes, definitely. Horizontal paddle dryers and the vertical dryers shown above provide comparable drying results.

As a rule, appliances with a vertically arranged mixing unit require less drive power than appliances with a horizontally arranged mixing unit. The peripheral speed can also be lower in vertical systems. This is particularly useful if the particle structure is to be preserved.

There are also interesting distinguishing features when comparing horizontal and vertical units. This concerns the method of diffusion and mixing.

Can an amixon® mixed dryer also be used as an evaporator for liquids?

Such detailed questions are quickly clarified when test drying trials are demonstrated in the amixon® technical centre. You are cordially invited to attend. In this context, many other questions can also be answered, for example on topics such as particularly gentle mixing, variable filling degrees or residual emptying.

© Copyright by amixon GmbH

![[Translate to English:] [Translate to English:]](/fileadmin/amixon/Articles/0012_FAQ_-_Vakuumtrocknung_mit_amixon_R__Mischtechnik/Siedetemperatur_von_Wasser.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/amixon/Articles/0012_FAQ_-_Vakuumtrocknung_mit_amixon_R__Mischtechnik/VMT_200_Versuchsmischer_mit_Person.jpg)