Highly viscous

Viscosity describes the flow behaviour of fluids, especially incompressible media such as liquids. It is a measure of the internal resistance that a fluid opposes to deformation by shear. Scientifically, viscosity can be defined as the ratio of shear stress to shear rate.

The unit of measurement for dynamic viscosity in the International System of Units is the pascal-second (Pa·s). In practice, however, the units millipascal-second (mPa·s) or the obsolete poise (P) are often used. Conversions between these units are possible, with 1 P = 100 mPa·s. Various methods are available for measuring viscosity, such as capillary viscometers, rotational viscometers or oscillation methods. The choice of method depends on the flow behaviour and viscosity range of the medium to be tested.

Thermal processes such as the evaporation of liquids usually result in an increase in viscosity. At the same time, the state of the substance can change, for example when dissolved salts crystallise and the liquid becomes a suspension. Such multiphase systems with unclear flow behaviour occur in many areas of the chemical and biotechnological industry. Examples include the enzymatic processing of starch, fermentation for penicillin production, and the recovery of dissolved solids from industrial process water. Other examples are the formulation of cosmetics, the processing of food pastes, and the manufacture of paints and varnishes.

The flow behaviour of liquids is not always constant. Many technical fluids behave non-Newtonian, meaning that their viscosity changes depending on the shear rate. Structurally viscous liquids (pseudoplastic) exhibit decreasing viscosity with increasing shear, while dilatant liquids become thicker with shear. Such effects occur during stirring, pumping or filling and influence process properties such as dripping behaviour, foam formation or the formation of air pockets.

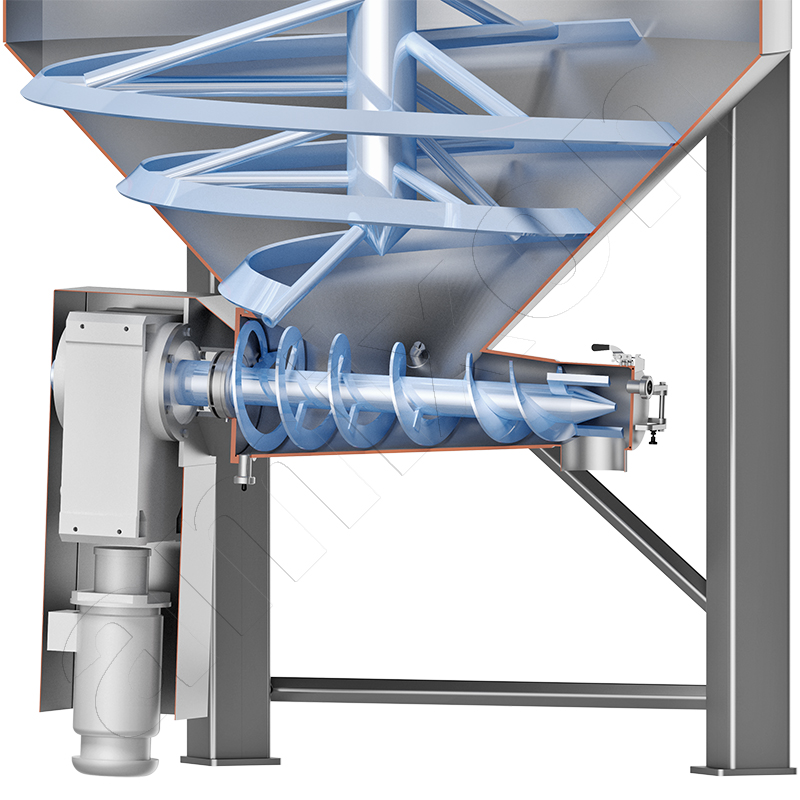

amixon® mixing systems are specially designed to reliably homogenise, process and discharge even highly viscous products – even in large quantities. In particular, cone mixers with SinConvex®mixing tools and Gyraton®mixers offer specific advantages for the safe and gentle processing of complex material systems. The performance of these systems can be demonstrated in a practical manner in the company's own technical centre.