GM 50 000 silo mixer for 50 m³ batches.

Silo mixer Gyraton®

The Gyraton® silo mixer is a precision mixer. It sets new standards for silo mixers in terms of mixing quality, flexibility and cost-effectiveness. Even with component compositions of one to one hundred thousand (1:100,000), it delivers ideal mixing qualities.

Maximum efficiency, tailored to your needs: you determine the mixing time and the motor size adapts precisely to it. For example, 22 kW of drive power is sufficient for mixing a 20 m³ batch. This is an efficiency advantage that has a direct impact on your operating costs.

Ideal mixing quality, small drive motor, compact design

The Gyraton® mixing silo requires only five to ten percent of the power of a conventional precision mixer. Nevertheless, it homogenises the mixed materials with the highest precision. The mixing process is extremely gentle.

The silo is very compact due to its cylindrical mixing chamber. For example, the Gyraton silo mixer for 70 m³ is less than 7.5 metres high. Compared to conical silo mixers, the height of the mixing chamber is reduced by two thirds. The compact design saves energy, as less vertical conveying is required during filling. This means less conveyor technology, less energy consumption, less cleaning effort and lower investment costs.

The bulk material also benefits. The shorter conveying distance protects the grain structure. This prevents heating and preserves the particle structure.

Easy delivery, installation and commissioning, hygienic design

The Gyraton® mixing silo is easy to transport and comes almost completely pre-assembled. It is transported horizontally and only erected at the installation site. For sizes up to 100 m³, the transport height (including vehicle) is less than four metres. Transport can be by road, rail or water.

The mixing chamber is gas-tight and hygienic. It can be cleaned dry or wet. Gyraton® mixing silos meet the highest purity requirements. On request, the silo mixer can be temperature-controlled. Even sensitive products can be mixed or fermented safely.

Large inspection doors in OmgaSeal® design facilitate cleaning. Gyraton® silo mixers are designed to be very durable. There are amixon® mixers that are still in use even after 40 years.

Gyraton® offers the best mixing quality without compromise – regardless of whether batch or continuous mixing is required

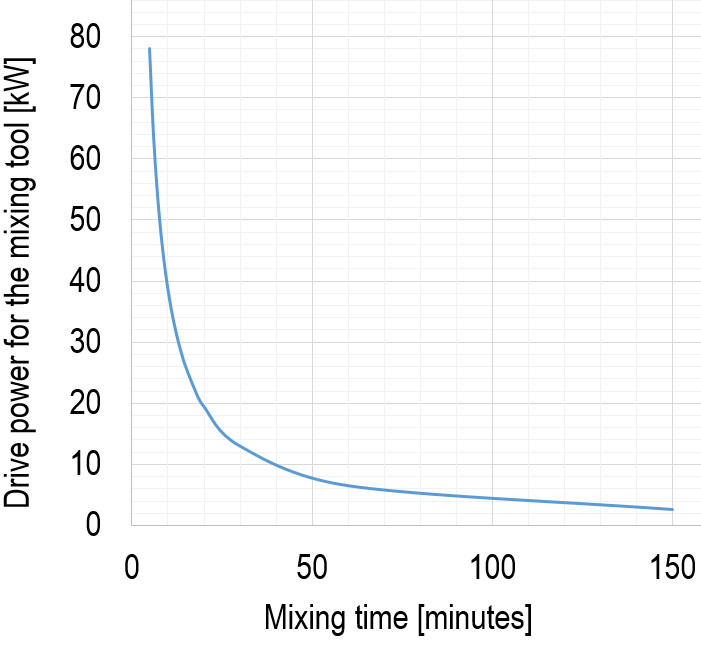

Precision mixers generally have high specific power requirements when used for powder mixtures (dry, wet or suspended). The required drive power is 20 to 30 kW per tonne of mixed material. This makes precision mixers uneconomical when large batches need to be mixed. For example, a 10 m³ mixer requires more than 100 kW. In most cases, however, more time is available than a large precision mixer requires (approx. 4 to 10 minutes).

The Gyraton® mixing silo always achieves optimum mixing quality. The mixing time can be selected by the operator. In most cases, mixing times of 30 minutes or several hours are acceptable. A small drive motor is then sufficient. The Gyraton® silo mixer can be operated both in batches and continuously.

The Gyraton® mixer achieves ideal mixing quality even with very slow mixing processes. The mixing tool performs two movements simultaneously. The shaft moves from the pivot point (gimbal centre at the top of the mixing chamber) in a precessional motion. At the same time, it rotates at a low speed. The lower mixing arm moves cycloidally over the bottom of the mixing chamber.

Since the radius of the lower mixing arm is significantly smaller than that of the mixing chamber, the required drive torque is low.

The Gyraton® silo mixer is the ideal solution for your mixing tasks if ...

- The batch size is at least 3 m³ and at most 100 m³.

- The materials to be mixed are dry powders, pastes or slurries with small and/or large particle diameters.

- The materials to be mixed flow well or poorly.

- The material compositions are homogeneous or heterogeneous: nanodisperse particles and granulates.

- The bulk densities vary between 0.01 kg/dm³ and 3 kg/dm³.

- The materials to be mixed can clump when at rest.

- The materials to be mixed are highly pure and are processed under sterile or inert conditions.

- The batch sizes vary between 10% and 100%.

- The mixed materials should be completely discharged after mixing.

- ...

What options are available for testing the Gyraton® silo blender?

A Gyraton® mixing silo with a gross volume of 4.8 m³ is available at the technical centre. The maximum batch size is 3 m³. Tests are only useful if at least 3 m³ of mixed material is available. Joint trials often give rise to new ideas. In any case, they minimise the risks of your investment decisions.

Based on the test data obtained, amixon® develops a reliable projection for the desired size. It goes without saying that all employees are bound to confidentiality.

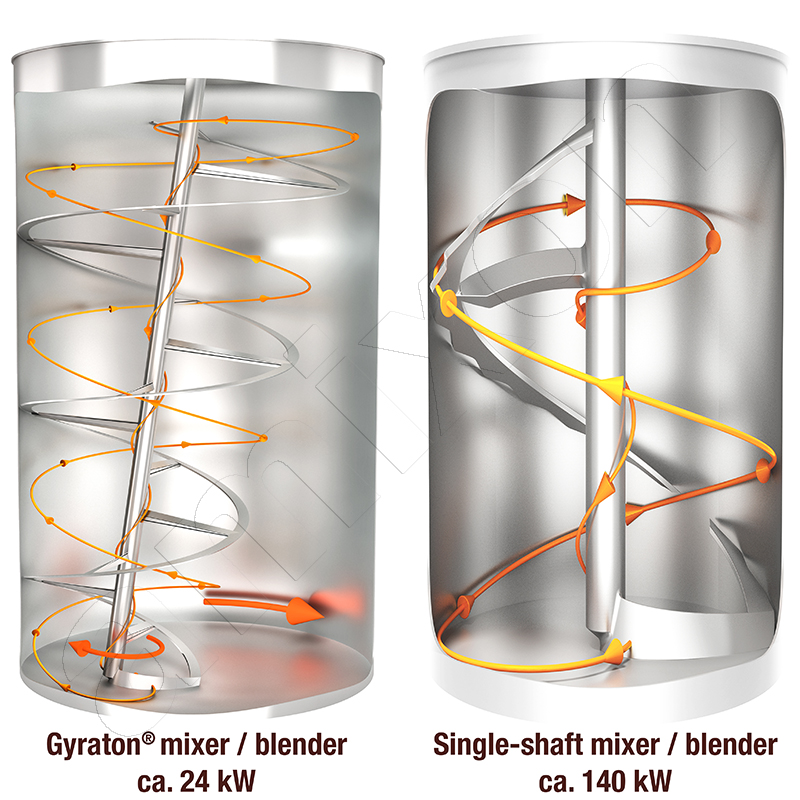

Comparison of two amixon® precision mixers

The amixon® vertical mixer shown on the right is used in a chemical factory for powder metallurgical goods. Its batch volume is 20 m³. The spiral mixing tool must rotate at a minimum of ten revolutions per minute. The drive motor requires around 140 kW of power for this. After a mixing time of 12 minutes, an ideal mixing quality is achieved.

The newly developed Gyraton® mixing silo (shown on the left) can also perform the same mixing task – and much more efficiently. Its drive motor requires only 24 kW of power. The mixing time is extended to around 60 minutes. However, this is not an issue in this application. In an 8-hour shift, no more than one batch of 20 m³ of metal powder can be produced anyway.

The low rotation frequency also saves energy costs and reduces wear.

Examples of applications for Gyraton® mixers

The Gyraton® mixer is particularly suitable for raw materials used at the beginning of long process routes. The Gyraton® mixer guarantees an undisturbed process and a homogeneous end product.

Pharmaceutical products

- Vitamins

- Penicillin

- API raw materials and API finished products

- Lactose (as excipient)

- Lactose (as excipient)

- talc (as a flow agent)

- stearates

- raw material for metal salts

- powdered enzymes or wet enzymes

- basic substrates for enzymatic synthesis

- ......

Organic products

- Cereals: wheat, corn, barley, rye.

- Thickening agents

- Food stabilisers

- Plastic stabilisers

- carboxymethylcellulose

- cellulose acetate

- Cellulose nitrate

- Carboxymethylcellulose

- Methylcellulose

- Hydroxyethylcellulose

- Ethylcellulose

- Coffee

- Tea

- Spices

- Oilseeds: soya, rape, sunflower

- Animal feed: soya meal, bran, pellets

- Rice: bulk storage and transport

- Sugar: cane and beet sugar

- Starch derivatives (corn, potato, rice)

- Protein powders (whey powder, soy protein)

- Instant beverage powders

- Cocoa powder

- Base masses for spice processing

- Raw materials for pet food

- Seed coating

- ...

Mineral and metallic raw materials

- Lithium hydroxide

- Lithium carbonate

- Cobalt

- Chromium

- Nickel

- Rare earths

- Neodymium

- Dysprosium

- Iron alloys

- Alumina: For aluminium production

- Copper concentrates: For metal processing

- Graphite: For batteries

- Solid lubricants

- Activated carbon

- Power plant coal, coking coal

- Ores: Iron ore, copper ore, bauxite, nickel ore, chromium ore

- Salts: Sodium chloride, potash, gypsum

- Sand and gravel: For the construction industry

- Limestone: For cement and steel production

- Cement: Raw material or end product

- Fertilisers: Nitrogen, phosphate and potash fertilisers

- Soda ash

- Kaolin

- Zinc oxide: For rubber and ceramic production

- Sulfur chemicals: For industry

- Electronic scrap

- Waste paper

- ......

Battery and storage technology

- Raw materials for cathodes and anodes (e.g. NMC, LFP, graphite)

- Powder for coated welding electrodes

- Separator coatings

- Components for solid electrolytes

- Lithium hydroxide

- Lithium carbonate

- Cobalt derivative

- Chromium salts

- ...

Energy raw materials

- Biomass for fermentation

- Wood flour and chips

- Ash and flue gas deposits

- ...

Industrial bulk materials

- Fertilisers: nitrogen, potash and phosphate fertilisers

- Sulphur: by-product of oil refining

- Chemical powders: lime, soda, silicates

- Scrap metal

- Recycling materials

- ...

Construction and infrastructure materials

- Artificial stone

- Slag and ash from the metallurgical industry

- Asphalt additives

- Clay

- Superplasticisers for concrete

- Powder-based sealants

- Cement-based fillers

- Fast-setting cement

- Gypsum plasters

- Dry mortar

- Pigments (titanium dioxide etc.)

Recycling/environmental technology

- filter dust

- soil improvement agents

- recycled materials in powder form (plastics, rubber)

- sewage sludge granulate

- exhaust gas cleaning materials

- activated carbon

- lime hydrate

- .....

Other

- explosives

- pyrotechnic raw materials (e.g. black powder components)

- abrasives and polishing agents

- ceramic raw materials

- Binders and additives in the production of lacquers

- Base compound for cosmetic powders

- .....

The Gyraton® mixer adapts precisely to your requirements

The Gyraton® mixer guarantees optimum mixing quality regardless of the rotational speed of the mixing tool. Whether rotating slowly or quickly, the result is always first-class. The following formulas apply to Gyraton® silo mixers within wide limits:

Rotational frequency · mixing time = C1

In vertical spiral mixers, the drive torque remains largely constant as long as ‘push mixing’ takes place. The drive torque is largely independent of the rotational frequency. In this respect, the following also applies:

Drive power · mixing time = C2

C₁ is a dimensionless constant.

C₂ is a constant with the unit kW · minute.

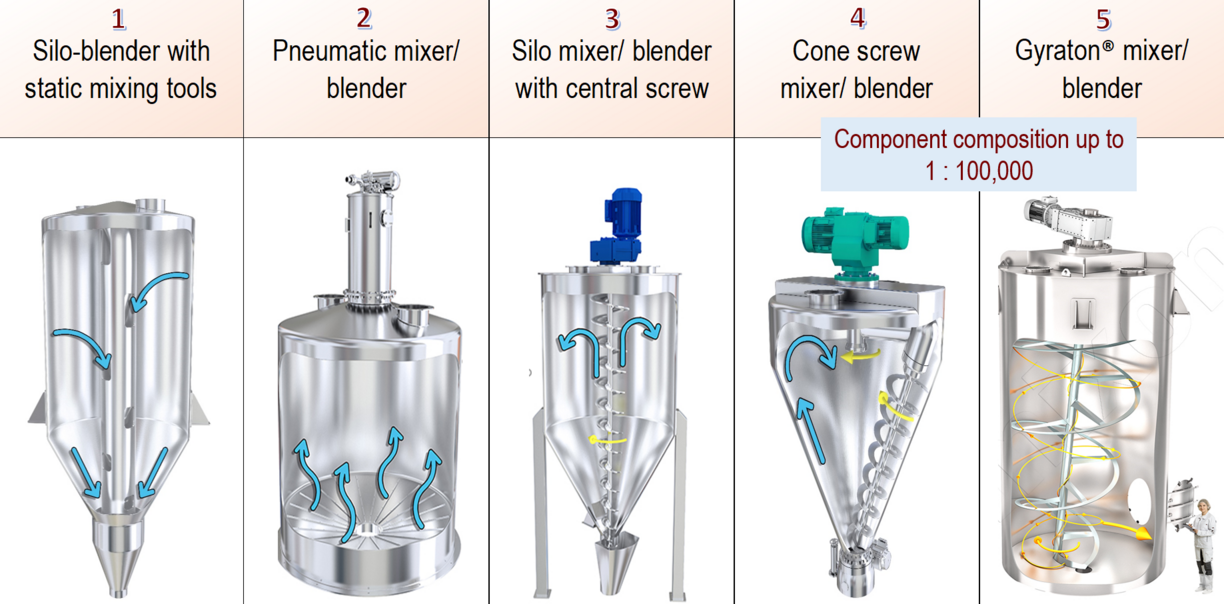

Explanations of silo blenders

Re 1)

This silo mixer is mainly used for plastic granulate with very good flow properties. Inside the mixer there is a pipe with side openings and baffles. During emptying, the products from the different areas flow together.

Re 2)

This silo mixer mixes by introducing large quantities of air or gas into the mixture. This is done in pulses at varying points in the base. The materials to be mixed must have similar properties in terms of: bulk density, grain size, flowability, fluidisability, freedom from agglomeration, etc. All materials to be mixed must be dry and easily fluidisable.

Re 3)

This is a silo mixer with a centrally located screw conveyor. This mixer is also not a precision mixer. However, it is suitable for mixing dry and free-flowing components. However, it can sometimes be difficult to ensure that the powders flow evenly down the silo wall.

Re 4)

This is a conical screw mixer with a circumferential screw conveyor. This mixer can be used to mix both dry and moist powders. It can also be used at different fill levels. The drive power is relatively low. High mixing qualities can be achieved with long mixing times. The mixing chamber is difficult to access. Its height is three times higher than that of a Gyraton® silo mixer.

Re 5)

The Gyraton® mixing silo represents a major advance in bulk material processing technology.

- It is designed to save space.

- It is economical in terms of energy consumption.

- It is suitable for goods that flow well and poorly.

- It achieves ideal mixing quality.

- It works at a wide range of filling levels.

- It is designed to be particularly hygienic.

- It can discharge the mixing goods to a high degree (SinConcave® and ComDisc®).

- It can be flexibly adjusted in terms of mixing time and drive power.

© Copyright by amixon GmbH