The processing challenges of mixing plant based meat substitutes

Producing vegetarian and vegan meat alternatives with amixon® powder mixers

The trend towards eating vegetarian and vegan meat substitutes is now an integral part of today's consumer culture. It is therefore no wonder that established meat processors in the food industry and start-ups are pursuing the idea of creating sausages, meats and barbecue products from plant-based raw materials. As a result, significant investments are being made to develop the optimal vegetarian or vegan meat substitute, and they are proving successful. Once unimaginable, vegetarian or vegan sausages no longer have to shy away from serious comparison with traditionally manufactured products.

Continuous production versus batch production

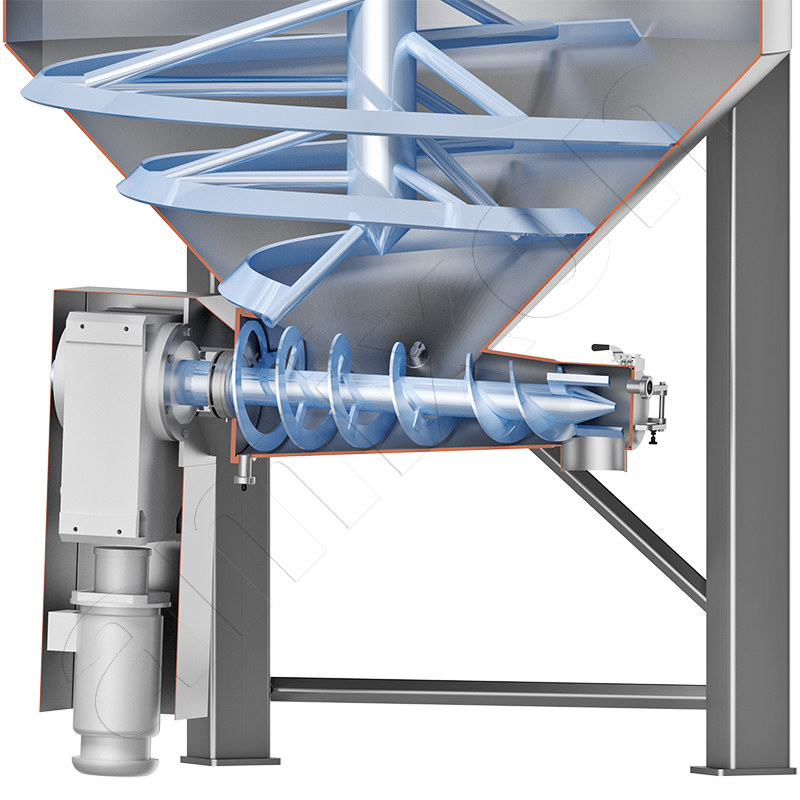

amixon® offers two highly developed mixing systems that are ideal for continuous processing. Both systems have been tried and tested for many years and are in use worldwide.

- Cone Mixer (Type AMK): This mixer works extremely gently and preserves the particle structure of the components. It can be operated both discontinuously and continuously, and delivers technically ideal mixing goods. It is also able to compensate for minor dosing fluctuations.

- Ring layer mixer (RMG): This system effectively deagglomerates agglomerates and lumps. It can also wet and agglomerate powders extremely quickly. The RMG is particularly interesting when processes or reactions are to proceed quickly and a very short residence time is required.

-

amixon® offers two highly developed mixing systems that are ideal for continuous processing. Both systems have been tried and tested for many years and are in use worldwide.

- Cone Mixer (Type AMK): This mixer works extremely gently and preserves the particle structure of the components. It can be operated both discontinuously and continuously, and delivers technically ideal mixing goods. It is also able to compensate for minor dosing fluctuations.

- Ring layer mixer (RMG): This system effectively deagglomerates agglomerates and lumps. It can also wet and agglomerate powders extremely quickly. The RMG is particularly interesting when processes or reactions are to proceed quickly and a very short residence time is required.

Many refinement steps are necessary

Form, consistency, taste and mouthfeel: considerable efforts are needed to make plant-based alternatives truly comparable to traditional schnitzels, steaks or burgers. Many meat substitutes now achieve a remarkable similarity to real meat – they look similar, have a comparable texture, a familiar mouthfeel and a similar smell. Even preparation at home often follows the same steps.

But the road to a high-quality product is long and challenging. Only if the flavour is convincing will a product become a bestseller. Ultimately, it is the consumer alone who decides whether the product tastes good and whether the price is right.

Often, the recipe contains more than 30 individual components, and the production process involves numerous steps. Almost all thermal and mechanical processes are accompanied by a careful mixing process.

Form, consistency, taste and mouthfeel: considerable efforts are needed to make plant-based alternatives truly comparable to traditional schnitzels, steaks or burgers. Many meat substitutes now achieve a remarkable similarity to real meat – they look similar, have a comparable texture, a familiar mouthfeel and a similar smell. Even preparation at home often follows the same steps.

But the road to a high-quality product is long and challenging. Only if the flavour is convincing will a product become a bestseller. Ultimately, it is the consumer alone who decides whether the product tastes good and whether the price is right.

Often, the recipe contains more than 30 individual components, and the production process involves numerous steps. Almost all thermal and mechanical processes are accompanied by a careful mixing process.

© Copyright by amixon GmbH