The processing challenges of mixing plant based meat substitutes

Growing market for vegetarian and vegan meat substitutes

On the rise in recent years, now widely appreciated: The trend toward eating vegetarian and vegan meat substitutes has become an integral part of today's consumer culture. There are many reasons why consumers may wish to reduce or eliminate their meat consumption. Among many vegans and vegetarians, their primary motivation is ethical: they are concerned with animal welfare and object to factory farming. For others, their decision revolves around health: they may believe animal products to be unhealthy, in part because of the widespread practice of prophylactically administering antibiotics to animals.

Active contribution to climate protection

As a contribution to climate protection, the vegetarian and vegan way of life receives a topical reference. The ongoing discussions about climate protection strike a chord with many consumers of vegetarian and vegan meat alternatives. Furthermore, rising awareness about climate change and the growing world population has led to an ever-increasing number of consumers who see vegetarianism or veganism as an effective way to minimize their carbon footprints.

Indeed, industrial animal agriculture is a leading source of CO2 emissions. According to the German Federal Environment Agency, if every resident in Germany were to convert to a vegetarian diet, this would reduce carbon emissions by approximately 600kg per capita, leading to a national reduction of 30%.

It is therefore not surprising that both established meat processors and start-ups alike are pursuing this emerging market by using plant-based raw materials to create meat substitutes. Furthermore, many market leaders in the global food industry are backing this movement by investing considerable financial resources into the internal infrastructure and machinery needed to produce the perfect meat imitation.

As a contribution to climate protection, the vegetarian and vegan way of life receives a topical reference. The ongoing discussions about climate protection strike a chord with many consumers of vegetarian and vegan meat alternatives. Furthermore, rising awareness about climate change and the growing world population has led to an ever-increasing number of consumers who see vegetarianism or veganism as an effective way to minimize their carbon footprints.

Indeed, industrial animal agriculture is a leading source of CO2 emissions. According to the German Federal Environment Agency, if every resident in Germany were to convert to a vegetarian diet, this would reduce carbon emissions by approximately 600kg per capita, leading to a national reduction of 30%.

It is therefore not surprising that both established meat processors and start-ups alike are pursuing this emerging market by using plant-based raw materials to create meat substitutes. Furthermore, many market leaders in the global food industry are backing this movement by investing considerable financial resources into the internal infrastructure and machinery needed to produce the perfect meat imitation.

Powder preparation requirements for the production of vegetarian and vegan meat alternatives

In recent years, many meatless products, from sausages to cold cuts to burger patties, have increasingly come to rival traditionally produced meat products in taste tests. We still have a ways to go, however, before we can create a plant-based alternative that resembles a schnitzel or steak in terms of texture, taste, and mouthfeel. But in light of veggie alternatives becoming permanent fixtures on the menus of some of the world’s largest fast food chains, it is impossible to deny that meatless meat is now part of the mainstream. If the goal is to convince more people to eat less meat, plant-based substitutes must not leave anything to be desired in terms of taste, texture, and even aroma. Furthermore, these products should be easy to cook in ways that are familiar to consumers, such as through grilling or pan-frying.

This starts with the right preparation of raw materials: Fruit pits, legume and vegetable peels are more valuable than ever. They provide the fiber structures for vegetarian or vegan meat. The formulations often consist of more than 30 individual components. These can be dry, semi-solid or liquid and differ in density, particle size, rheology and stability.

Depending on the type of preparation, it may make sense to move from batch mixing to continuous mixing and vice versa. Decisive factors can be poorly flowing and adhering raw material components. Sometimes raw materials should be protected from contact with atmospheric oxygen.

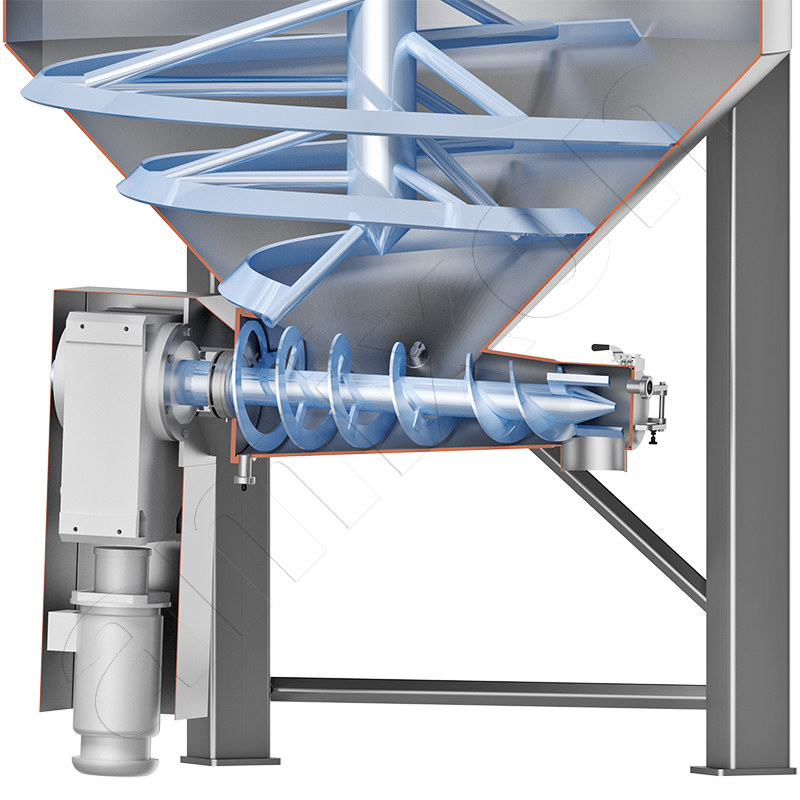

In the event that the masses should be prepared continuously, amixon® offers two types of continuous mixers: A pipe flow mixer or a boiler flow mixer.

The problem: The more frequently the recipe is changed and the more individual components are used, the more difficult it becomes to implement continuous mixing processes. The silver bullet often seems to be a batch-wise processing of the majority of the solid components into an intermediate component. Powdery or pasty goods, in contrast to liquid goods, are much more difficult to automate and meter.

In recent years, many meatless products, from sausages to cold cuts to burger patties, have increasingly come to rival traditionally produced meat products in taste tests. We still have a ways to go, however, before we can create a plant-based alternative that resembles a schnitzel or steak in terms of texture, taste, and mouthfeel. But in light of veggie alternatives becoming permanent fixtures on the menus of some of the world’s largest fast food chains, it is impossible to deny that meatless meat is now part of the mainstream. If the goal is to convince more people to eat less meat, plant-based substitutes must not leave anything to be desired in terms of taste, texture, and even aroma. Furthermore, these products should be easy to cook in ways that are familiar to consumers, such as through grilling or pan-frying.

This starts with the right preparation of raw materials: Fruit pits, legume and vegetable peels are more valuable than ever. They provide the fiber structures for vegetarian or vegan meat. The formulations often consist of more than 30 individual components. These can be dry, semi-solid or liquid and differ in density, particle size, rheology and stability.

Depending on the type of preparation, it may make sense to move from batch mixing to continuous mixing and vice versa. Decisive factors can be poorly flowing and adhering raw material components. Sometimes raw materials should be protected from contact with atmospheric oxygen.

In the event that the masses should be prepared continuously, amixon® offers two types of continuous mixers: A pipe flow mixer or a boiler flow mixer.

The problem: The more frequently the recipe is changed and the more individual components are used, the more difficult it becomes to implement continuous mixing processes. The silver bullet often seems to be a batch-wise processing of the majority of the solid components into an intermediate component. Powdery or pasty goods, in contrast to liquid goods, are much more difficult to automate and meter.

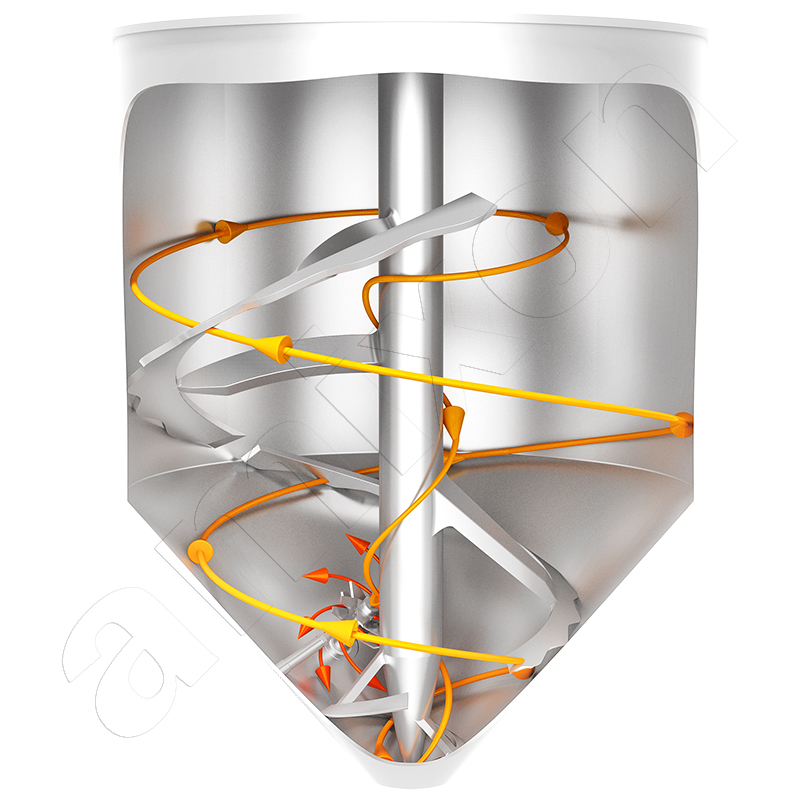

A conical mixer from amixon® mixes in a continuous boiler flow.

The conical mixer stands on load cells. Precisely operating dosing elements continuously feed the mixer with all components from above. In the lower section, the mixer has a shut-off valve that operates without dead space. This works on the basis of the weighing data. This keeps the filling level constant.

This amixon® continuous mixer type AMK is both a precision batch mixer and an accurate continuous mixer. The mixer rests on load cells and is equipped with a dead-space-free closing valve in the lower section. This is opened or closed according to the weighing data and the filling level is thus kept constant. Gravimetric powder feeders are installed above the mixing plant.

This continuous mixer with vertical mixing tool also mixes dry, wet and suspended solids as well as liquids of various viscosities.

The conical mixer stands on load cells. Precisely operating dosing elements continuously feed the mixer with all components from above. In the lower section, the mixer has a shut-off valve that operates without dead space. This works on the basis of the weighing data. This keeps the filling level constant.

This amixon® continuous mixer type AMK is both a precision batch mixer and an accurate continuous mixer. The mixer rests on load cells and is equipped with a dead-space-free closing valve in the lower section. This is opened or closed according to the weighing data and the filling level is thus kept constant. Gravimetric powder feeders are installed above the mixing plant.

This continuous mixer with vertical mixing tool also mixes dry, wet and suspended solids as well as liquids of various viscosities.

Excellent results from start to finish

The continuous mixer from amixon® is exemplary in its ability to produce nothing but top quality mixtures with zero product loss from start to end of a production campaign. At the beginning of a production campaign, all gravimetric feeding mechanisms start simultaneously, beginning with a low mass flow rate and automatically adjusting themselves in relation to one another. The filling level rises gradually, and the mixing action begins once half-capacity has been reached. This is also the point at which transient oscillation in the feeding mechanism is completed. Once the mixer has reached a filling level of 80%, the discharge slowly opens. From this point onwards, a filling level of 80% is kept constant. This is possible due to the gradual acceleration of the feeding

mechanism until the maximal mass flow rate has been reached. Finally, all feeding elements successively decelerate the mass flow, and eventually switch off and close at the same time. The SinConvex® mixing tool is able to discharge free-flowing mixing goods to a high degree. In this way, even the last remnants of homogeneous mixing goods are discharged at the end of the production campaign. From the beginning to the end of the mixing campaign, only defect-free, homogeneous product is produced.

The continuous mixer from amixon® is exemplary in its ability to produce nothing but top quality mixtures with zero product loss from start to end of a production campaign. At the beginning of a production campaign, all gravimetric feeding mechanisms start simultaneously, beginning with a low mass flow rate and automatically adjusting themselves in relation to one another. The filling level rises gradually, and the mixing action begins once half-capacity has been reached. This is also the point at which transient oscillation in the feeding mechanism is completed. Once the mixer has reached a filling level of 80%, the discharge slowly opens. From this point onwards, a filling level of 80% is kept constant. This is possible due to the gradual acceleration of the feeding

mechanism until the maximal mass flow rate has been reached. Finally, all feeding elements successively decelerate the mass flow, and eventually switch off and close at the same time. The SinConvex® mixing tool is able to discharge free-flowing mixing goods to a high degree. In this way, even the last remnants of homogeneous mixing goods are discharged at the end of the production campaign. From the beginning to the end of the mixing campaign, only defect-free, homogeneous product is produced.

Trials in the test center: Benefit from the know-how of the amixon® experts.

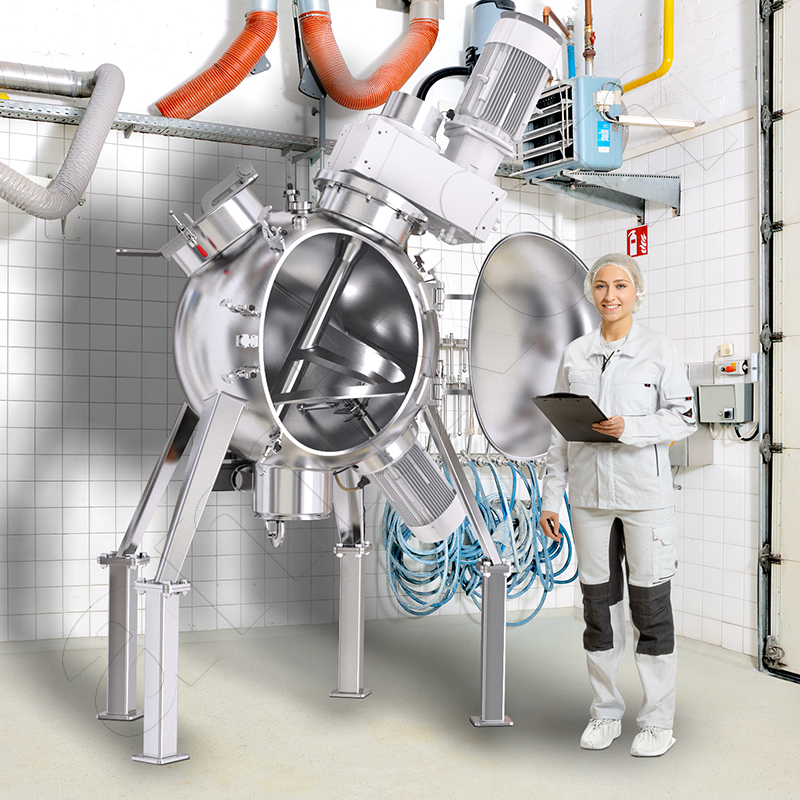

Learn more about the benefits of using the amixon® mixing technology. Contact us and we will support you with trials and demonstrations of your mixing processes in the production of vegetarian or vegan meat substitute products. We look forward to seeing you in our excellently equipped pilot plants in Germany, the United States, China, Japan, India, Thailand and South Korea.

Learn more about the benefits of using the amixon® mixing technology. Contact us and we will support you with trials and demonstrations of your mixing processes in the production of vegetarian or vegan meat substitute products. We look forward to seeing you in our excellently equipped pilot plants in Germany, the United States, China, Japan, India, Thailand and South Korea.

© Copyright by amixon GmbH