Mixing plants

Mixing plants are always designed in the context of the respective business model. Their technical design is based on economic objectives, product requirements and operational conditions. Therefore, identical or similar powder mixers can be used in completely different production environments.

In some companies, for example, the focus is on flexible, batch-oriented production. There, mixing plants are designed in such a way that frequent product changes, variable recipes and small to medium batch sizes are economically feasible. The focus here is on ergonomic feeding, fast cleaning processes and modular expansion options.

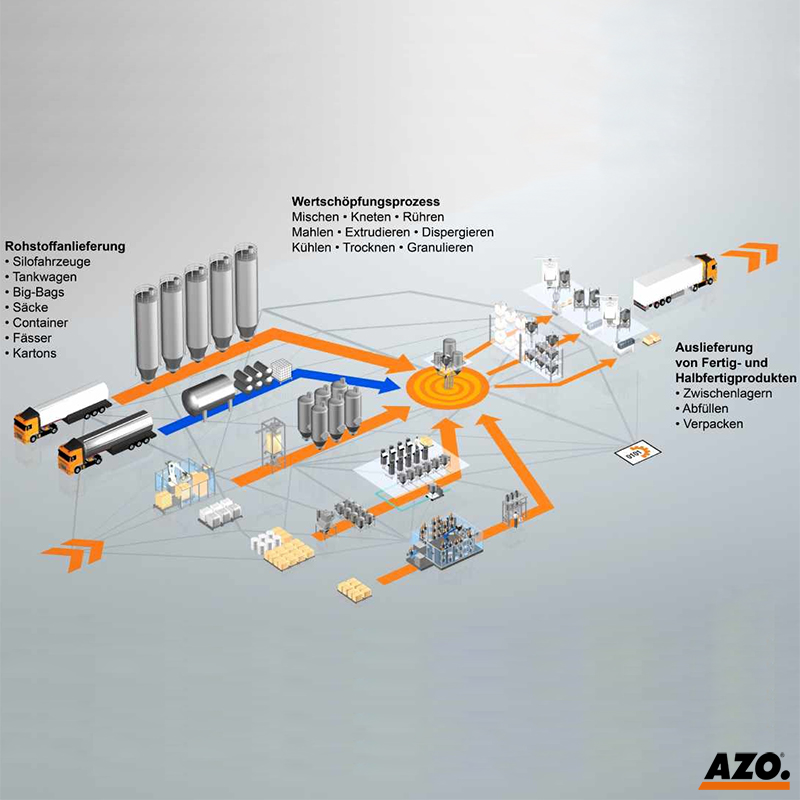

In other production environments, however, continuous or highly automated processes dominate. Here, powder mixers are integrated into complex material flow systems that must ensure high cycle rates, reproducible quality and minimal downtime. In such cases, the plant is designed to be more process-oriented. Automated conveying, dosing and packaging systems determine the layout, while the mixer acts as the central process node.

Industry-specific requirements also lead to different characteristics. In the food and pharmaceutical industries, for example, hygiene requirements, validatability and documentation obligations shape the plant design. In the chemical and building materials industries, robustness, explosion protection and energy efficiency are paramount.

The mixer is usually one of the most cost-intensive individual machines within the plant. However, the total value of a mixing plant significantly exceeds the value of the mixer. This is due to the scope of the peripheral systems and the degree of automation. With increasing automation, the performance of the plant, process reliability, operator independence and economic efficiency increase. A highly automated mixing plant is therefore a complex, process-oriented complete solution that integrates all steps from raw material input to the packaged end product.

The efficiency of a mixer and the entire plant increases when they can empty themselves completely. This increases output, saves raw materials and reduces waste. Ideally, the mixing plant only needs to be cleaned during inspections.

amixon® mixers can discharge themselves up to 99.97%.