Fermentation in the amixon® fermenter reactor

Microorganisms and enzymes are determinants of all biological processes. They can be specifically isolated and conditioned to modify substances. Even inorganic substances can be modified in this way; for example, in the processing of metallic ores and rare earths.

Bacteria, fungi and enzymes help produce pharmaceuticals, for example penicillin. Fermentation is used to modify starch, preserve food, polymerize environmentally friendly plastics, purify rare earths, produce alcohol, biogas, cheese, yogurt, yeast, baking dough or vinegar. Tea, coffee and tobacco are refined by fermentation. In addition, biological waste is fermented and clarified in the fermenter. The number of examples could be continued at will.

Typically, fermentation processes take place in aqueous nutrient solution. To ensure complete mass transfer, agitators are installed in the fermentation vessel. They can be shaped like a propeller, an anchor or a helix. In general, the requirements for such an agitator are as follows:

- Low investment costs

- Small design

- Hygienic design and installation

- Good mixing with low energy input

- Low shear energy so as not to damage the microorganisms

- short switch-on time with the aim of saving energy

As long as the fermentation substrates are low viscosity, a simple, small agitator can diffuse and mix a large mass. Sometimes the mixing process is improved by either installing a baffle or by installing the agitator outside the axis of symmetry. An intermittent, swelling, or reversing mode may also be helpful. As long as the viscosity of the fermentation substrates is similar to water, i.e. low, agitators can achieve sufficient mixing.

The situation becomes more difficult when the viscosity increases, becoming comparable to curd cheese, cream cheese or margarine. Then three challenges must be accomplished:

- How can the homogenization of large batches take place?

- How can a gentle homogenization process be ensured?

- How can the resulting mass be discharged safely and at the same time in a metering manner?

amixon® fermenters multiply microorganisms particularly gently with high efficiency

The fermentation process can optionally be supplemented very effectively by stimulating the process parameters:

- mechanical agitation

in the form of dispersing and homogenizing or

in the form of compaction and kneading, - Temperature,

- pH value

- Presence of enzymes in the nutrient substrate,

- Pressure,

- Gas atmosphere,

- Oxygen supply,

- …….

The apparatus described here is derived from our amixon® conical mixer/reactor.

Question from a customer: Sometimes the fermentation results are highly viscous, poorly flowing, and sensitive to pressure and shear. Then they are difficult to mix, and it is difficult to carry them out. Are there suitable fermenters for such highly viscous goods?

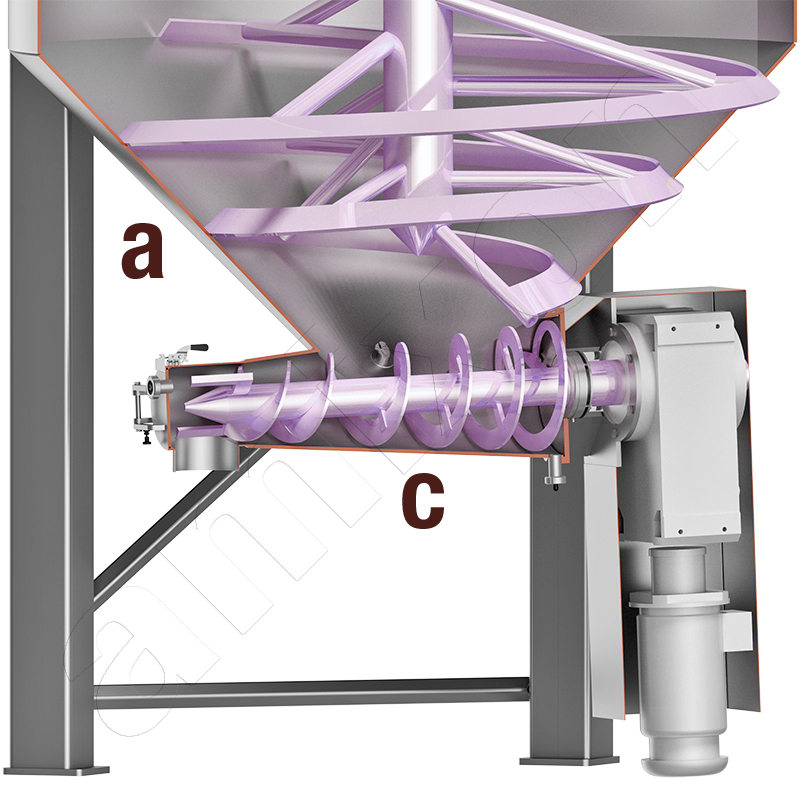

Answer from amixon®: Yes, they are available as amixon® conical fermenters in vertical design. A convex helical mixing tool rotates slowly inside. This design can be used for almost all rheological consistencies; low viscosity, high viscosity, semi-solid plastic masses.

The 20 m³ fermenter shown here is equipped with automatic cleaning and sterilization equipment. It processes highly viscous compounds.

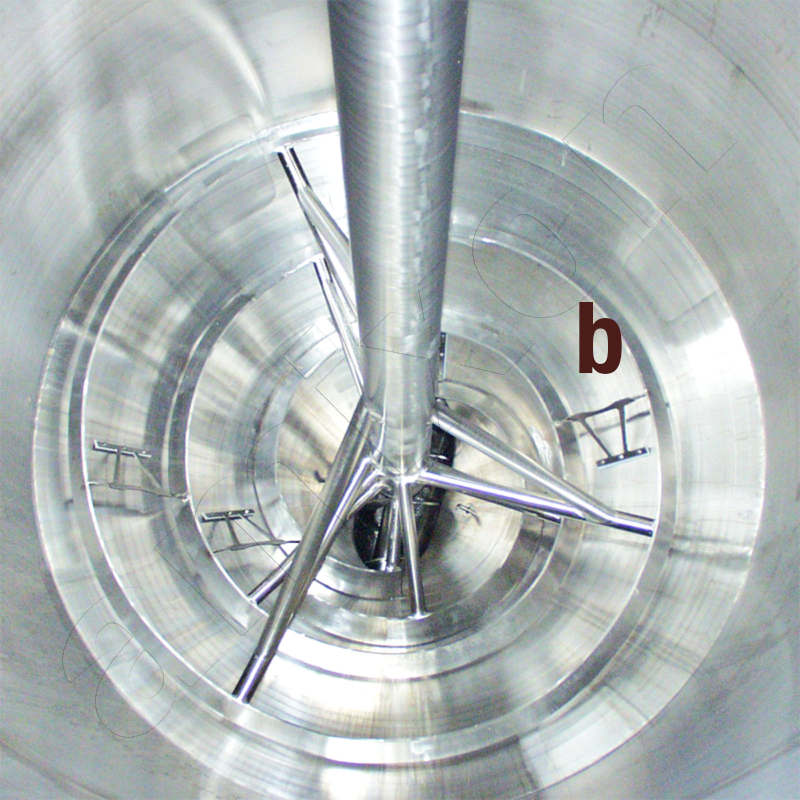

Gentle homogenization is carried out with a spiral mixing tool (a). Flexible scraping tools (b) are optionally installed between the spirals. In the case of the mixing function, the goods are conveyed upwards. For discharge, the mixer rotates in the opposite direction and conveys the fermented goods downward into a conically shaped dosing system (c). This allows the discharge mass flow to be dosed out with high precision (continuously).

Both tools, the spiral mixing tool and the horizontally mounted discharge system, are mounted and driven on one side only. They are hygienically designed and microbiologically cleanable. On request, the design can be done in order to discharge against a different pressure level (overpressure or vacuum). The entire system rests on load cells.

Learn more about "Load cells and weighing of mixed materials"!

© Copyright by amixon GmbH