ComDisc®

On the world market, there are only a few mixers that empty the mixture automatically and completely.

amixon® has solutions for this challenge in use worldwide: the discharge tool is called ‘ComDisc®’. The name is derived from the English term ‘complete discharge’.

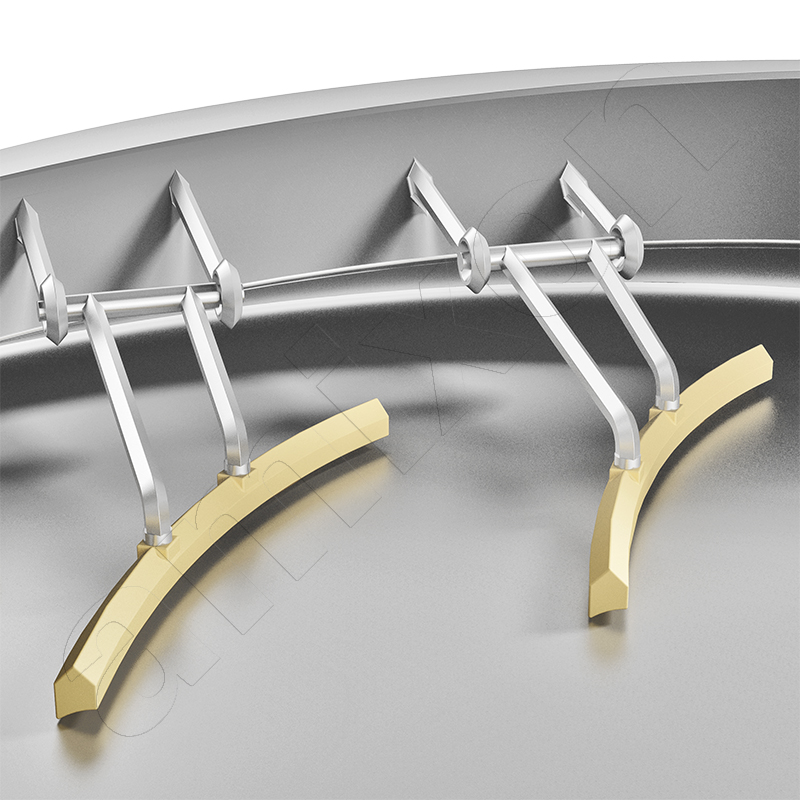

amixon® mixers empty up to 99.997% and better with ComDisc®. The ComDisc® tools are mounted on the lower mixer arm. During the mixing process, the ComDisc® is in the flow shadow and floats on the mixture. As the filling level decreases, the ComDisc® tools sink to the bottom of the mixer. In doing so, they push the remaining mixture to the outlet. Almost all of the mixture is discharged very quickly and effectively.

More efficiency and sustainability

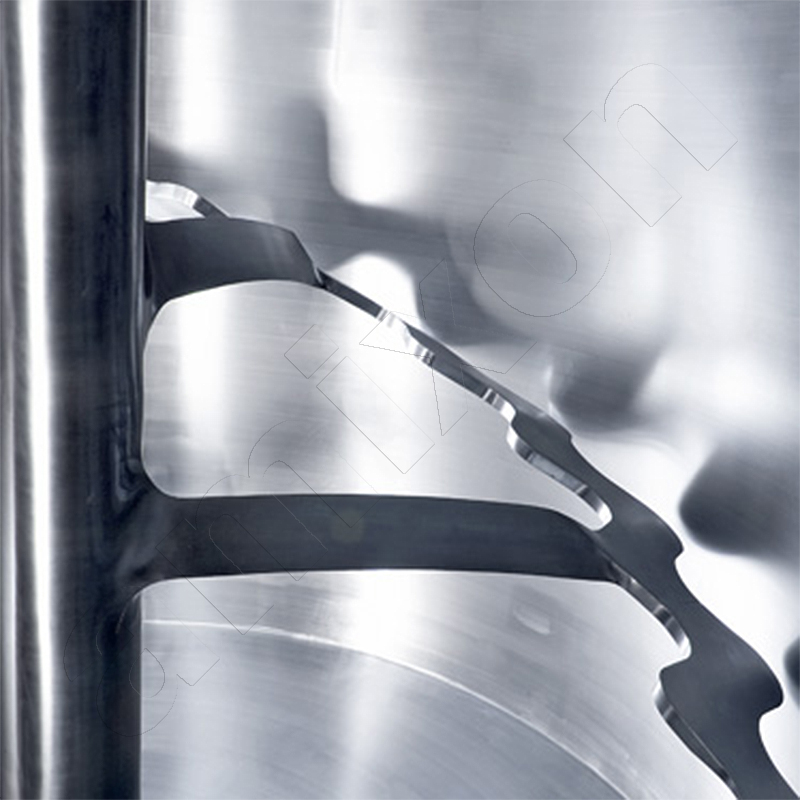

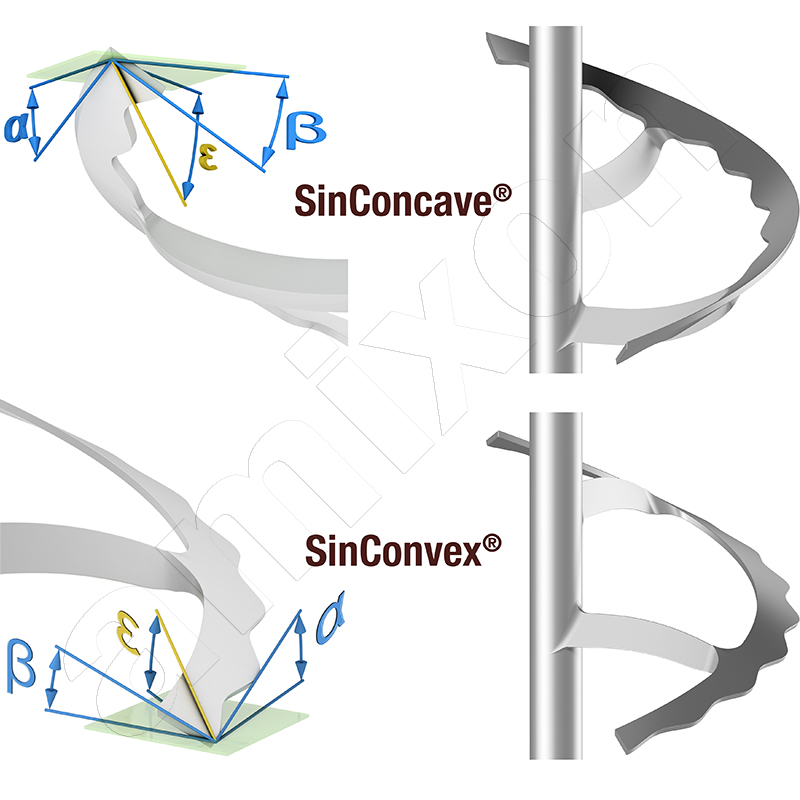

ComDisc® is an excellent addition to SinConvex® or SinConcave® mixing tools. Its inclined spirals create ideal mixing effects and have excellent self-cleaning properties.

Almost all raw materials are refined and sold. There is hardly any waste. There is much less cleaning to be done. Your business will be more sustainable in terms of efficiency and resource conservation.

Further solutions for complete emptying can be found at amixon® conical mixers and KoneSlid® mixers.

Retrofitting for older amixon® mixers

In conjunction with SinConcave®/SinConvex® technology, the mixer can be emptied almost completely. The entire mixture is discharged without segregation, cleaning times are reduced and raw materials can be saved. The entire production process is more hygienic and efficient.

The advantages of ComDisc® are not limited to new mixers. Existing mixers can also be retrofitted with ComDisc® / SinConvex® and ComDisc®.

© Copyright by amixon GmbH