amixon® conical mixer for Marinades, dips, sauces, ketchup or spray ingredients

The production of dips, fillings and sauces begins with powder mixing/preparation.

Before powder mixtures can be processed into sauces, dips, spreads or ketchup, the powder mixer has to carry out important processes. Liquids such as seasoning extracts, oleoresins, lecithins, fats, oils, lecithins and liquid flavourings must be distributed microfine in the powder. The liquids have different viscosities. Some of the liquids cannot be mixed with each other. They are then incorporated into the powder one after the other. This slightly agglomerates the powder mixture. Dusting powder components are bound. In particular, highly viscous liquids must be distributed agglomerate-free in the powder. In the amixon® mixer, the powders are mixed and agglomerated dust-free. They are then sufficiently free-flowing. After just 40 to 160 revolutions of the mixing spiral, technically ideal mixing qualities are achieved that can no longer be improved in practice.

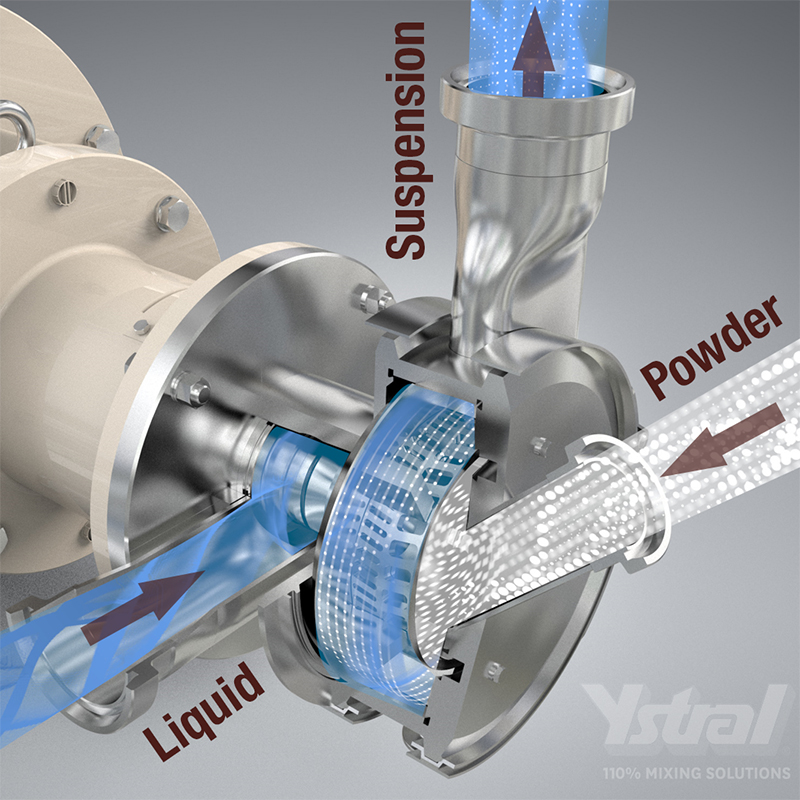

The subsequent homogenisation of the liquids is carried out using rotor-stator systems or high-pressure shear homogenisers. These liquid mixing systems are not part of the amixon® production programme.

If the finished powder mixture fulfils the following criteria, high-quality liquid products (dips, sauces, ketchup, remoulades, sweet cake mixes, desserts, instant food, delicatessen) can be produced:

- the powder is free from agglomerates and lumps

- the powder remains cool

- the mechanical energy input is minimal

- the powder is free-flowing

- the powder is dust-free

- the powder is homogeneous

In special cases, the powder mixer can be temperature-controlled and vacuum-proof. A vacuum can be applied after mixing. The ambient air is removed from the powder and replaced by a mixture of carbon dioxide and nitrogen gas. Oxidation is reduced. The powder packaged in this way has a longer shelf life and can be processed elsewhere.

amixon® powder mixers: seasoning, spicy flavours for snacks, premixes for sauces, dips, remulders, instant and delicatessen products

The two identical amixon® conical mixers produce the powdered high concentrates (premixes) and the main mixtures one after the other in the same mixing machine. The powders are then filled into big bags. The liquid end products are produced at a different location.

If a mixer is placed on load cells, the desired filling weight of the big bag can be set fairly accurately. This big bag filling system is coupled with a dedusting system. The air content of the big bag is displaced by the dusty mix. - The air flow generated by the dedusting system must not distort the weighing signal.

Please also read our article on achievable weighing accuracy.

The two identical amixon® conical mixers produce the powdered high concentrates (premixes) and the main mixtures one after the other in the same mixing machine. The powders are then filled into big bags. The liquid end products are produced at a different location.

If a mixer is placed on load cells, the desired filling weight of the big bag can be set fairly accurately. This big bag filling system is coupled with a dedusting system. The air content of the big bag is displaced by the dusty mix. - The air flow generated by the dedusting system must not distort the weighing signal.

Please also read our article on achievable weighing accuracy.

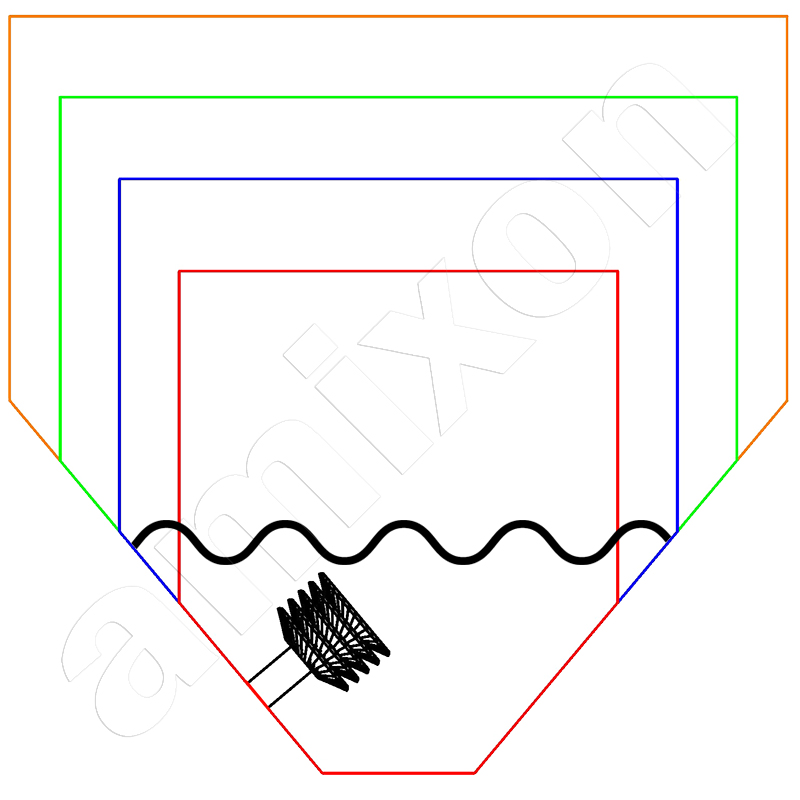

A multi-stage mixing process requires the highest mixing quality regardless of the filling level.

amixon® conical mixers are ideal for multi-stage mixing processes. The fast-rotating cutting rotor is completely covered by the mix even at low filling levels. This allows it to develop its high dispersing/deagglomeration performance even at low filling levels.

This "Multi_Step" feature enables complex powder preparation in just one mixer. There is no need for a premixer for small, highly concentrated batches.

The different colours stand for conical mixers of different sizes. The position of the cutting rotor does not change with the different sizes. It is interesting to note that the relative filling level flexibility increases with the size of the conical mixer.

amixon® conical mixers are ideal for multi-stage mixing processes. The fast-rotating cutting rotor is completely covered by the mix even at low filling levels. This allows it to develop its high dispersing/deagglomeration performance even at low filling levels.

This "Multi_Step" feature enables complex powder preparation in just one mixer. There is no need for a premixer for small, highly concentrated batches.

The different colours stand for conical mixers of different sizes. The position of the cutting rotor does not change with the different sizes. It is interesting to note that the relative filling level flexibility increases with the size of the conical mixer.

Dry cleaning, wet cleaning, manual or automatic. Optionally, an amixon® mixer can also be sterilised with steam or hot gas.

The amixon® mixers comply with the relevant hygiene guidelines. They can also be antibacterially cleaned and sterilised on request. The cleaning concepts are varied. Depending on the task and sensitivity of the raw materials, cleaning can be dry or wet. With amixon® systems, cleaning is ergonomic and convenient.

Automatic wet cleaning can be advantageous if very different products are produced in mixed operation. Steam sterilisation can also be carried out automatically if the temperature of the mixing chamber can be controlled. The mixing chamber should then be pressure and vacuum-tight.

WaterDragon® cleaning systems can also dry the mixer/vacuum dryer/synthesis reactor automatically.

The amixon® mixers comply with the relevant hygiene guidelines. They can also be antibacterially cleaned and sterilised on request. The cleaning concepts are varied. Depending on the task and sensitivity of the raw materials, cleaning can be dry or wet. With amixon® systems, cleaning is ergonomic and convenient.

Automatic wet cleaning can be advantageous if very different products are produced in mixed operation. Steam sterilisation can also be carried out automatically if the temperature of the mixing chamber can be controlled. The mixing chamber should then be pressure and vacuum-tight.

WaterDragon® cleaning systems can also dry the mixer/vacuum dryer/synthesis reactor automatically.

© Copyright by amixon GmbH