minimum ignition energy

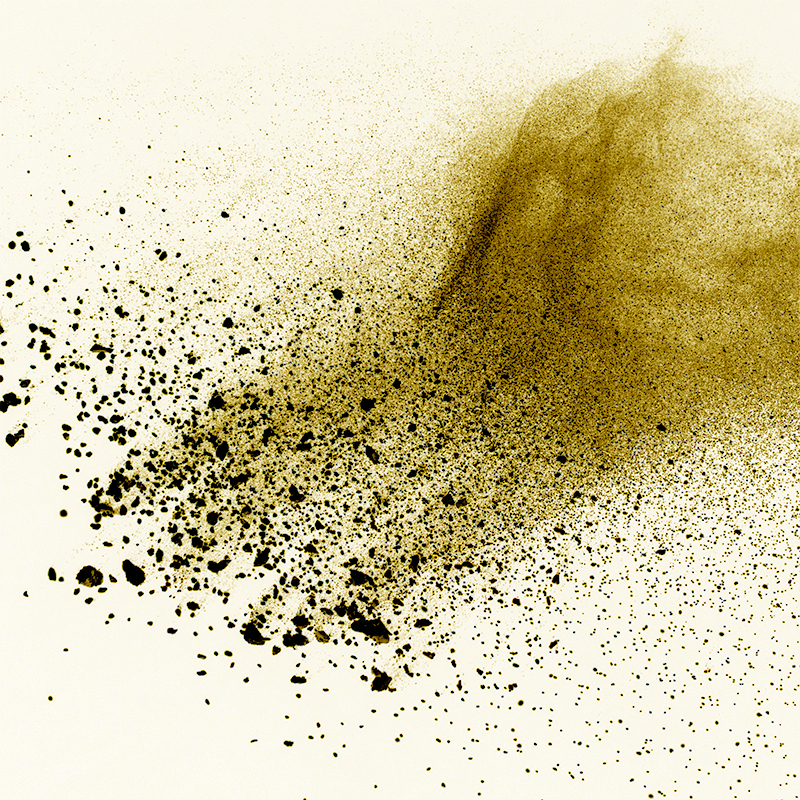

The minimum ignition energy is the smallest amount of energy required to ignite a combustible system. In the context of bulk solids processing technology, this primarily concerns dusts that arise from dry solid particles. Dust forms as soon as particles are moved or bulk solids are handled openly. Combustible fine particles can react very quickly and burn explosively at the right concentration and with an effective ignition source. Such events have destroyed entire plants in the past and pose a considerable risk to people.

The minimum ignition energy is determined using special testing equipment that generates a reproducible dust cloud and provides defined electrical spark energies. A specified dust concentration is dispersed for a short time. The dust-air mixture is then exposed to a series of electrical ignition pulses with increasing or decreasing energy. The smallest spark energy that reliably causes the most ignitable dust mixture to react is derived from the interaction of tests with and without ignition. The resulting minimum ignition energy depends on the particle size, moisture content, surface structure and temperature.

It is an important parameter for the design of safety measures and for the classification of dusts. Typical categories range from "extremely sensitive to ignition" (up to 3 mJ) to "particularly sensitive to ignition" (3 to 10 mJ) to "normally sensitive to ignition" (above 10 mJ). While literature references exist for many pure bulk solids, experimental determination is necessary for powdery mixtures.

amixon® is authorised to issue ATEX certificates. The entire machine range has been certified accordingly on the basis of extensive type examinations. The ATEX-certified process machines from amixon® may be used for the processing of certain explosive substances and mixtures.