Using a vacuum dryer to toast flour and deactivate enzymes

The amixon mixers and sterile reactors offer a wide range of applications. They can thermally treat flours or other organic powders and mix and dry them under vacuum.

They can process the sterile powders obtained into specialty baking agents.

You can further process the masses obtained into tablet masses. Their range of applications in the solid-liquids industry is particularly wide.

Some reasons for this are:

- FLEXIBILITY: In amixon® mixers and reactors, the filling levels can vary greatly without sacrificing efficiency.

- QUALITY/REPRODUCIBILITY: amixon® machines achieve ideal mixing qualities that cannot be improved in practice.

- PROCESS RELIABILITY: amixon® machines meet the most stringent hygienic requirements.

- TRACEABILITY: amixon® machines can be emptied very thoroughly. This helps to ensure contamination-free production.

Sterilisation and processing of cereal flour as a pharmaceutical carrier substance

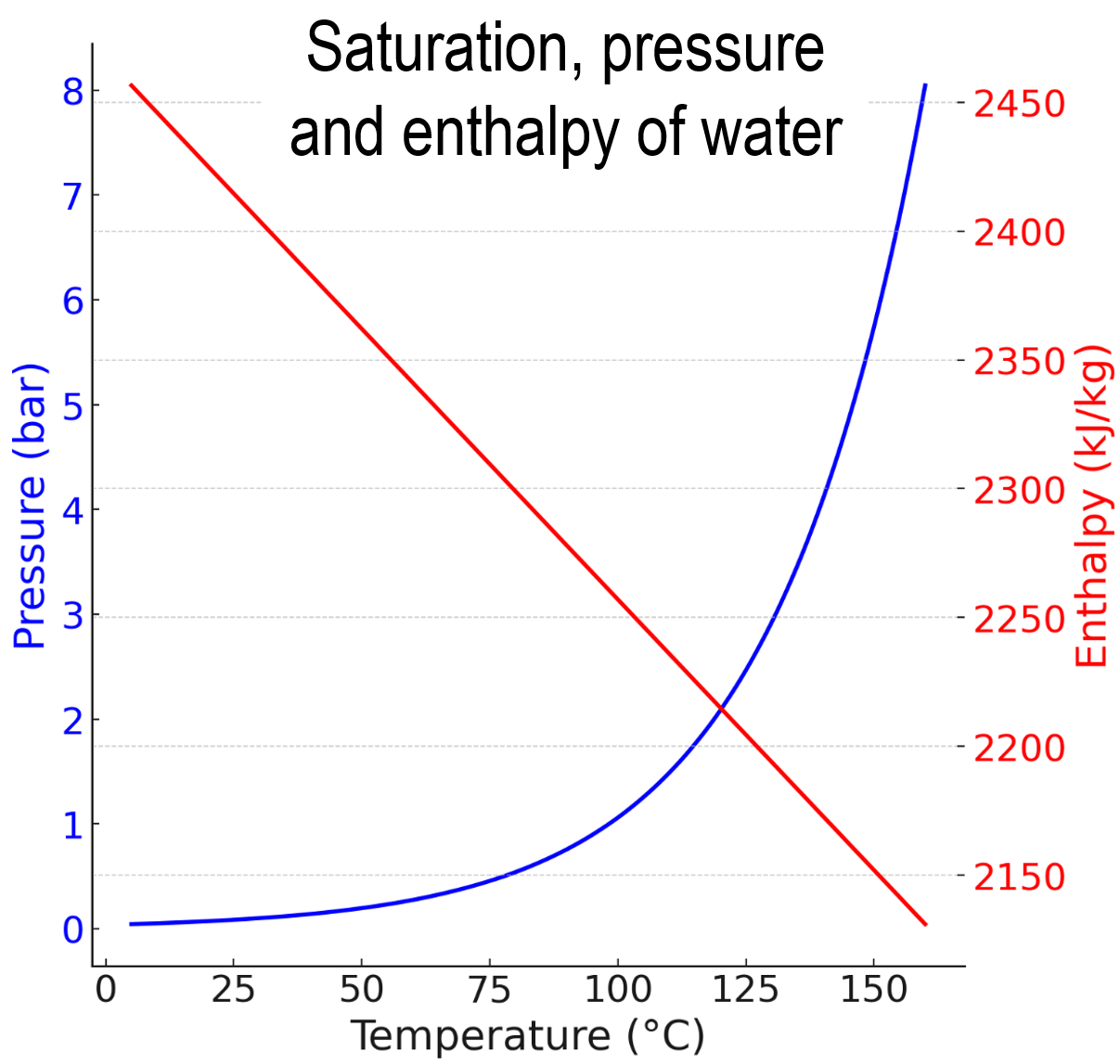

Cereal flours and derivatives are also used in the production of carrier substances for pharmaceuticals. The flours are heated under vapour pressure in the amixon® mixing reactor. Sterilisation takes place at 130 °C. The system pressure is increased to approx. 3 bar absolute. The residence time is approx. 20 minutes. The vapour is then blown off. This is followed by vacuum drying and cooling.

The treated flour is then free from spores and microorganisms. The starch contained in the flour is partially gelatinised. The resulting mass can be used as a filler for tablet masses. The amixon® mixers are also capable of homogeneously mixing in active medical ingredients. The mixtures produced in this way are generally easy to tablet.

The amixon® team will be happy to support you in extrapolating the data. amixon® mainly carries out its tests on a 200-litre scale. Industrial plants can be up to 100 times larger.

Cereal flours and derivatives are also used in the production of carrier substances for pharmaceuticals. The flours are heated under vapour pressure in the amixon® mixing reactor. Sterilisation takes place at 130 °C. The system pressure is increased to approx. 3 bar absolute. The residence time is approx. 20 minutes. The vapour is then blown off. This is followed by vacuum drying and cooling.

The treated flour is then free from spores and microorganisms. The starch contained in the flour is partially gelatinised. The resulting mass can be used as a filler for tablet masses. The amixon® mixers are also capable of homogeneously mixing in active medical ingredients. The mixtures produced in this way are generally easy to tablet.

The amixon® team will be happy to support you in extrapolating the data. amixon® mainly carries out its tests on a 200-litre scale. Industrial plants can be up to 100 times larger.

Thermally treated cereal flour has improved instant properties

Grain flours can be thermally treated in various ways for the bakery industry. This changes the starch structure and inactivates enzymes. Doughs made from denatured flours have altered baking properties. In addition, the shelf life of so-called long-life baked goods can be improved. The same applies to the shelf life of frozen doughs.

In some companies, the thermal treatment of cereal flour is also referred to as toasting, as the flour can take on a slightly roasted flavour.

Thermally treated flour generally has good flow and pouring properties. It wets well with both water and oils.

Hydrothermally treated flour is a natural stabiliser and binding agent that is used in the production of dressings, sauces and creams. It is used in numerous catering and confectionery products.

Grain flours can be thermally treated in various ways for the bakery industry. This changes the starch structure and inactivates enzymes. Doughs made from denatured flours have altered baking properties. In addition, the shelf life of so-called long-life baked goods can be improved. The same applies to the shelf life of frozen doughs.

In some companies, the thermal treatment of cereal flour is also referred to as toasting, as the flour can take on a slightly roasted flavour.

Thermally treated flour generally has good flow and pouring properties. It wets well with both water and oils.

Hydrothermally treated flour is a natural stabiliser and binding agent that is used in the production of dressings, sauces and creams. It is used in numerous catering and confectionery products.

© Copyright by amixon GmbH