Mechanical alloying

Mechanical alloying produces materials that cannot be manufactured using conventional metallurgical methods. Typical reasons for this are widely differing melting points of the alloying partners, insufficient homogeneity due to different densities, or the lack of miscibility of certain elements in the liquid state.

To circumvent these limitations, the starting materials are converted into a state with a very large specific surface area. They then exist as fine powders that can be combined with each other in precisely defined proportions. In precision mixers, such as those manufactured by amixon, these powders can be processed into a homogeneous mixture with almost ideal mixing quality. Uniform distribution of the particles is crucial in order to achieve a homogeneous microstructure and uniform mechanical properties in the compacted material.

After mixing, various methods are available for compacting the powder. These include extrusion, tableting, roller compaction and isostatic pressing. While the first methods are based on the application of directional mechanical force, isostatic pressing is characterised by the application of uniform pressure to the entire workpiece.

In isostatic pressing, the powders are filled into flexible, tube-like sleeves. These sleeves are sealed gas-tight and placed in a pressurised water bath. Increasing the water pressure applies an even load to the packaging from all sides. This is why it is referred to as isostatic pressing. This process produces very dense and high-strength workpieces, which can then be further processed using machining techniques.

Furthermore, mechanical alloying can already be initiated during the mixing process itself. amixon® manufactures appropriate intensive mixers. They are particularly suitable for abrasive powders. Processing is carried out by deagglomeration and by subjecting the particles to impact and shear stress. At the microscopic level, this can stimulate diffusion processes and solid bonds between the particles. The result is fine-grained and often nanostructured materials with special properties such as high strength, hardness or corrosion resistance.

Mechanical alloying, together with nanotechnology, opens up new possibilities in materials development, especially for material combinations that cannot be alloyed using conventional methods.

Compaction equations in powder metallurgy

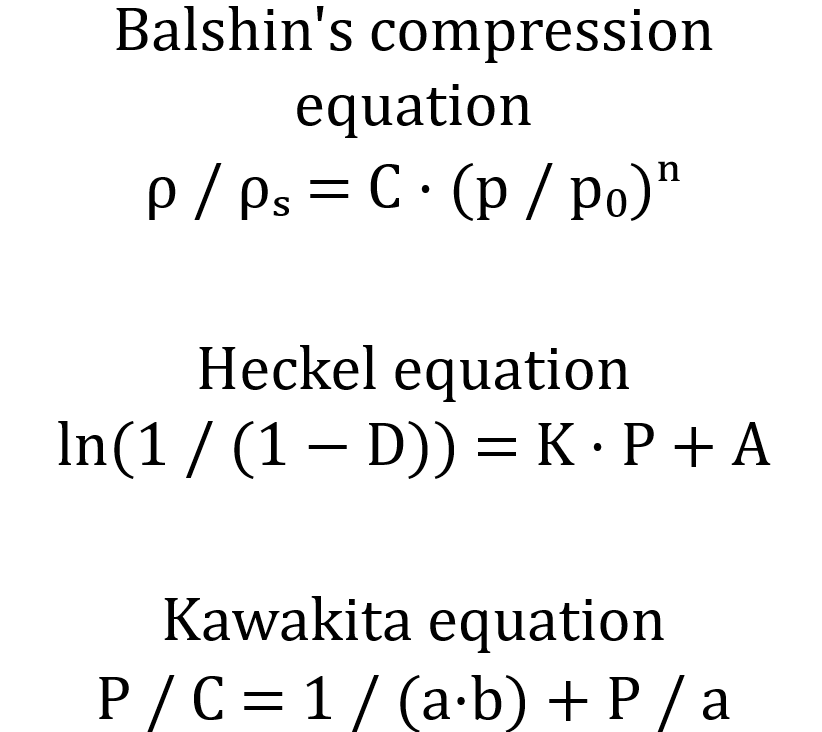

Empirical compaction equation according to Balshin

This equation describes the relationship between the relative density of the powder and the applied pressing pressure:

ρ / ρₛ = C · (p / p₀)ⁿ

Meaning:

ρ = current density of the compacted powder

ρₛ = theoretical density of the solid material

p = applied pressing pressure

p₀ = reference pressure

C, n = empirical constants (depending on material, grain size, lubrication, pressing direction)

This formula is often used in cold compaction and describes the typical exponential increase in density with increasing pressure.

Heckel equation

The Heckel equation is one of the best-known formulas for describing the plastic deformation of metal powders under pressure.

ln(1 / (1 − D)) = K · P + A

Meaning:

D = ρ / ρₛ = relative density

P = pressing pressure

K = material constant (reciprocal to yield stress)

A = empirical constant (dependent on particle packing and friction)

The linear range of this relationship is used to characterise the plastic behaviour of the powder. The reciprocal of K approximately corresponds to the yield stress of the powder during compaction.

Kawakita equation

This equation is used in particular for powdered materials with high compressibility (including pharmaceutical or ceramic powders):

P / C = 1 / (a·b) + P / a

Meaning:

P = pressure

C = (V₀ − V) / V₀ = relative volume reduction

V₀ = initial volume

V = volume after compression

a, b = material constants

a describes the maximum possible compressibility, b relates to pressure sensitivity.