Grain structure

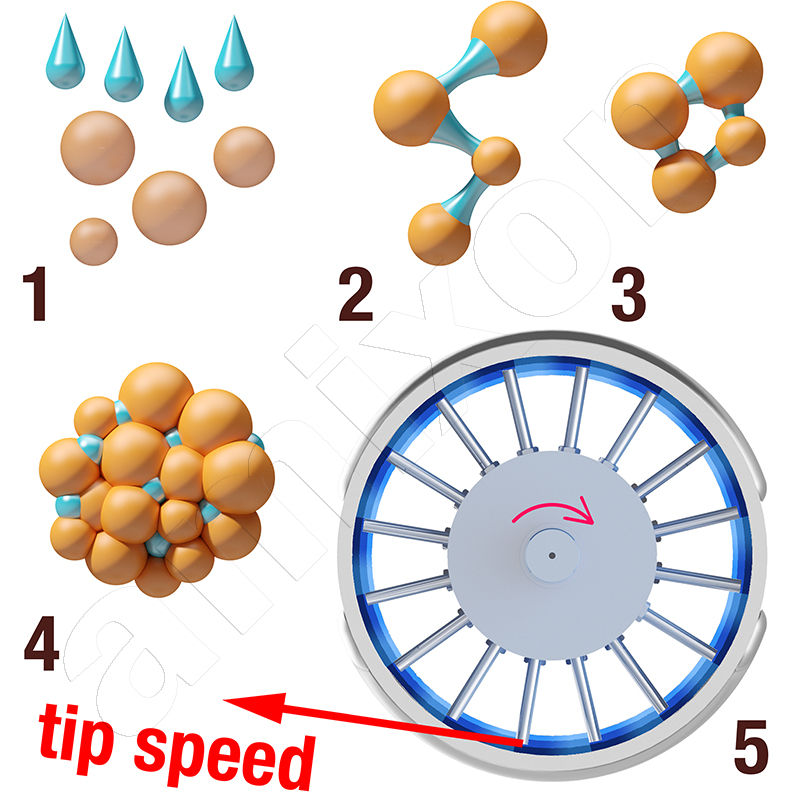

Particle structure is a key issue in bulk material technology. The quality characteristics of high-grade powders are based on the following criteria: flow behaviour, freedom from dust and dosability. Agglomeration combines primary particles into larger grains without changing their chemical composition. This results in grains with specific strength and porosity. There are various agglomeration processes. Agglomeration is used in the food and pharmaceutical industries, in raw material extraction, in chemistry and in building materials technology, among others.

Water is the preferred binding agent. This promotes various mechanisms. First, liquid bridges are formed, which turn into solid contacts during drying. In water-soluble systems, the mechanism of vitrification also occurs. In this process, particle surfaces partially dissolve when wetted. When the water evaporates, an amorphous, glass-like layer remains, which acts as an adhesive. This effect can produce very stable agglomerates, but also makes the materials sensitive to moisture.

Agglomeration not only improves the handling of powders, it also controls reactivity, surface area and solubility.

Depending on the process control, dense or porous structures are created that can be specifically adapted to the respective application. Process engineers use modern mixers and granulators to precisely adjust the particle size and stability.

A special form of particle structure is coating. Coating with liquids or solids can bind dust, protect active ingredients or specifically adjust release profiles. Coating often also serves to protect against moisture or oxidation. Uniform layer formation is crucial, which can only be achieved with controlled flow control in the process.

Particle structure is therefore much more than just a coarsening of powders. Agglomeration and coating create added value through improved product properties and functional additional benefits. It can be very challenging for process engineers to establish a stable agglomeration process. A continuous agglomeration process is usually preferred. Ring layer mixing granulators from amixon GmbH can agglomerate almost all types of powder. They usually achieve uniform particle diameters. In any case, trials in the technical centre are necessary to achieve good results.