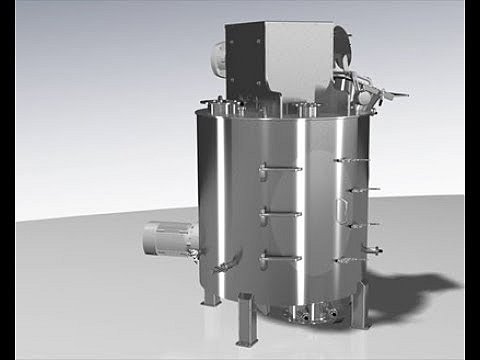

Vertical single-shaft mixer / ribbon blender (VM)

Ideal mixing quality for dry, moist and viscous materials at variable filling levels

The spiral mixing blade inside the ribbon blender initiates a three-dimensional flow of the mixing goods; creating a helical upward movement on the periphery and downward flow in the centre. This industrial mixer guarantees very good mixing results and complete discharge. It can be used as ribbon blender for dry powder, wet suspensions as well as liquids, paste and dough.

The vertical mixer can be designed for compliance with FDA and 3-A Sanitary Standards to be used as a sterile mixer and reactor which also meets EHEDG requirements.

Further characteristics of the single-shaft mixer / ribbon blender:

- If the mixing process requires deagglomeration, high speed cutting rotors can be installed.

- The ribbon blender is driven from the top, using only a single top bearing.

- The mixer meets all industry standards for surface finish, including sanitary and pharmaceutical requirements.

- Jacketed and vacuum rated versions are an ideal vacuum dryer or mixing reactor.

There is currently a gently-used VM Mixer available for purchase.

Product Videos

Contact us

amixon GmbH

Halberstaedter Strasse 55

33106 Paderborn

Germany

Telephone: +49-5251-688888-0