microtrace element

Microtracers are defined, finely distributed indicator substances that are used for quantitative analysis of the mixing quality in powdered bulk materials. They are usually present as dry, non-agglomerated particles with a narrow particle size distribution and do not influence the product properties due to the low concentrations used. Frequently used systems are based on colour pigments such as patent blue, which can be reliably detected in concentrations as low as 1 : 100,000. In the dry state, the distribution of the tracer is not detectable. Only after complete dispersion of a sample in a suitable solvent does a measurable colour intensity develop.

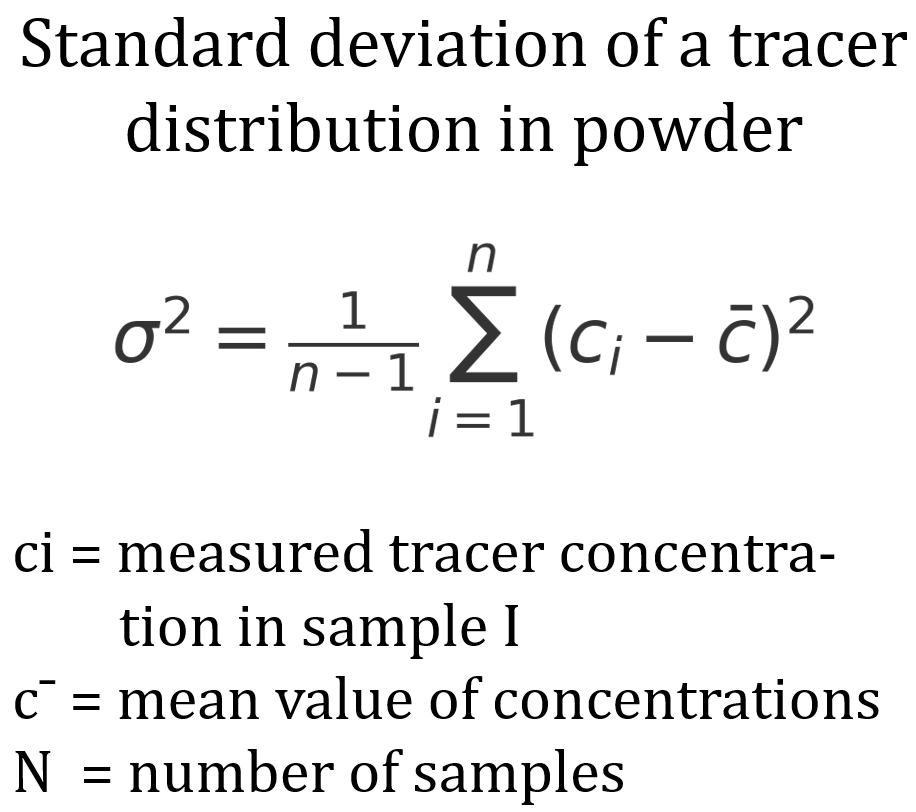

Quantitative evaluation is performed spectrophotometrically using Lambert-Beer's law. The optical absorption depends linearly on the molar extinction coefficient of the dye, the concentration of the solution and the layer thickness of the cuvette. Calibration curves can be used to determine the mass fraction of the tracer in the sample, from which the local mixing quality can be derived. This method allows statistically reliable statements to be made about the homogeneity, segregation tendencies and mixing kinetics of different devices.

In addition to dye-based microtracers, there are other systems that use alternative physical measurement principles. Historical work by the University of Karlsruhe demonstrates the use of weakly radioactive microparticles that were introduced into bulk material. With the aid of suitable detectors, it was possible to record both the spatial distribution of the particles and their transport paths during the mixing process. In experiments with ploughshare mixers, fundamental insights into particle redistribution, convection currents and macroscopic mixing mechanisms were derived from this.

Microtracers thus enable high-resolution analysis of real mixing processes and are an essential tool for characterising and optimising powder mixing processes.