Powder Drying

Vacuum drying bulk materials and suspensions

What does vacuum drying mean in industry?

What is commonly understood as vacuum mix drying is in most cases vacuum contact drying. Heat energy is transferred into the mix through mechanical contact with a heated surface. When vacuum is applied, the boiling temperature of the liquid phase that one wants to remove by drying decreases. This accelerates the drying process. The accompanying mixing process ensures that all particles are heated. They repeatedly come into contact with warm surfaces. In a few cases, thermal energy is introduced in the form of infrared radiation or microwave radiation. This form of energy input / drying is used in smaller plants (on a litre scale).

Vacuum drying iis a separation process in which liquid is evaporated. In industrial powder drying, the substance to be moved is water or a solvent. Drying is usually done by adding heat.

How is the heat energy introduced into the product?

In convection drying, the mixed material is heated by bringing it into contact with heated gas. The hot gas sweeps over the mix and absorbs the liquid phase in the form of vapour. Saturated gas is removed and dry hot gas is added.

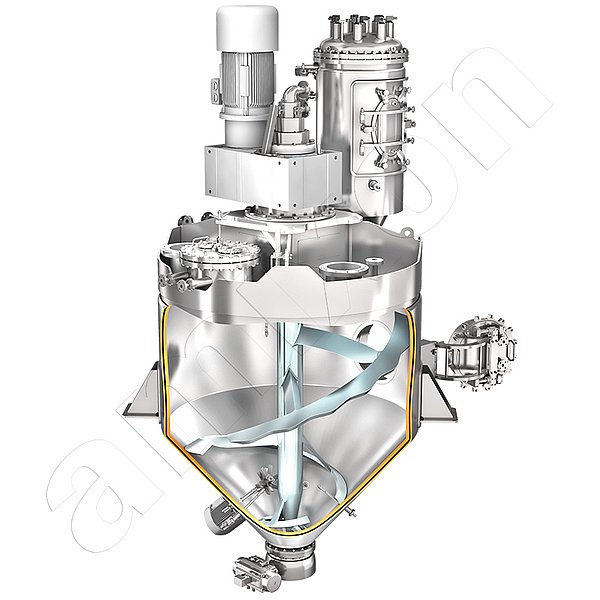

Contact drying: Heat energy is transferred into the mix by mechanical contact. The wall of the mixing vessel and possibly also the mixing tools are the heated surfaces. Vacuum mixing dryers from amixon® work according to this functional principle.

Roller dryers also work as contact dryers. Roller dryers operate at atmospheric air pressure. They operate at high temperatures.

Freeze drying: Also known as lyophilisation. The water-moist product is first frozen and then a vacuum is applied. The liquid phase sublimates. The ice converts directly into water vapour. The liquid phase is skipped. Thermal energy is supplied by contact heat or radiant heat. This drying process is particularly gentle. The mixture remains cryogenically cold. In this way, thermosensitive active substances are dried in a frozen state.

Drying with superheated water vapour: Unsaturated water vapour has a strong absorption effect when passed over moist bulk materials. This drying process is carried out at atmospheric pressure and heats the bulk solids to 110°C at most. The presence of the water vapour eliminates the atmospheric oxygen. This prevents unwanted oxidation. As a rule, the moist bulk material is in thin layers. This accelerates heating and drying.

Convection drying vs. contact drying

Laundry on a clothesline dries by convection and, if the sun is shining, by radiation.

Convection drying has many advantages for bulk goods: In spray drying, the spray droplets produced only come into contact with hot gas. The powder particles form and dry undisturbed. In fluid bed granulation, the moist powder bed is swirled and carried and conveyed by the hot gas (air). The particles can dry well and optionally agglomerate. The agglomerates are usually quickly soluble and dispersible.

Disadvantages of convection drying:

If hot air is present, the powders can oxidise. Another disadvantage is that the energy input is greater than with vacuum contact drying. A drying system that works on the basis of convection is relatively large because large quantities of air have to be processed: Air cleaning, cooling and drying, heating, bar separation, heat recovery.

Vacuum contact drying; advantages

Vacuum mix dryers are very compact and require little installation space. In many cases the drying goods are sucked in. Drying takes place in a closed system. Only the fluid is discharged in liquid form. Any dust that is produced remains in the system. Drying is very effective at low temperatures if a high-quality vacuum is applied. Thermally sensitive active substances are preserved. Water can already evaporate at 35°C.

The amixon® vacuum contact dryers AMT and VMT dry your mixed materials extremely gently. The powders are effectively heated and agitated. amixon® units are designed to be particularly hygienic. They often also serve as synthesis reactors.