conditioning

In bulk solids technology, conditioning refers to the targeted adjustment of powder properties so that they meet the requirements of processing and application. Although the term is not strictly scientifically defined, it is frequently used in practice.

- Dust binding is a key objective. For this purpose, fine particles are agglomerated or bound by additives so that the bulk material remains dust-free even when moving.

- Another area is instantisation. In this process, primary particles are bonded together in such a way that porous agglomerates are formed. Such structures are easily wettable, sink quickly into liquids, are easily dispersed and dissolve completely.

- The flow properties of powders can also be improved by conditioning. Agglomerated powders flow much better than fine dusts. They are easier to store in silos or bags.

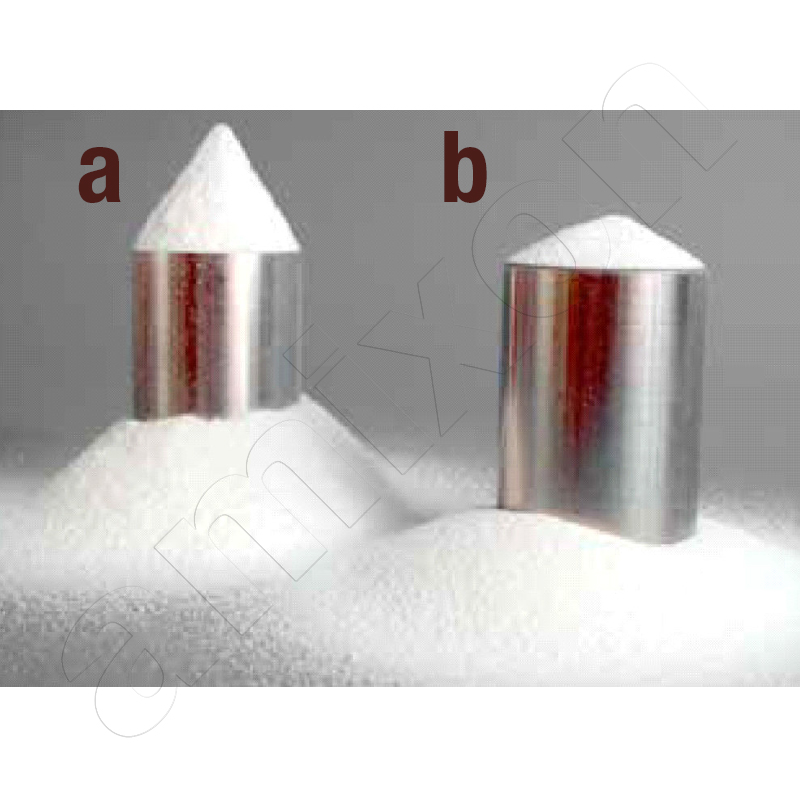

- Another option is coating. In this process, moist powders are coated with flow aids such as silicon dioxide, starch or talcum in order to increase their flowability and prevent caking. Powder (b) flows better than powder (a).

- Colouring can also be added during conditioning. After all, instant beverage powders should not only be functional, but also visually appealing.

- Another common goal is to increase the bulk density. In the case of metal powders intended for compaction or sintering, a denser bulk material must be produced through intensive mixing movements, deaeration and deagglomeration.

The list of possible measures is open and varies depending on the industry and application. Conditioning therefore covers a wide range of physical and chemical modifications that can be used to specifically improve the process behaviour and product properties of bulk solids.