Compacting

During compaction, loose powder particles are compacted so that they adhere to each other. This is desirable in many applications. Examples include effervescent tablets, medicinal pills, briquettes made from lignite, ceramic moulded bodies or agglomerated instant products.

Unwanted sticking or clumping, on the other hand, occurs when powder clumps together. This can happen in silos or bags. Washing powder can also harden into blocks in the packaging. Unwanted powder adhesion can also occur on mixing tools, on container walls or in conveyor pipes. Such effects can sometimes be avoided. For example, an anticaking powder can be added to the powder or the moisture can be reduced. Air conditioning the production plant also often has a positive effect. The colder a mix leaves the mixer after the mixing process, the less it tends to clump together. At this point, the twin-shaft mixers and KoneSlid® mixers from amixon® are particularly recommended.

There are different methods for intentional particle adhesion. Ring layer mixing granulators from amixon® can be used for this purpose, which can be tested in the technical centre. A simple formula can be used to roughly estimate the required compaction. The frequently observed relationship is

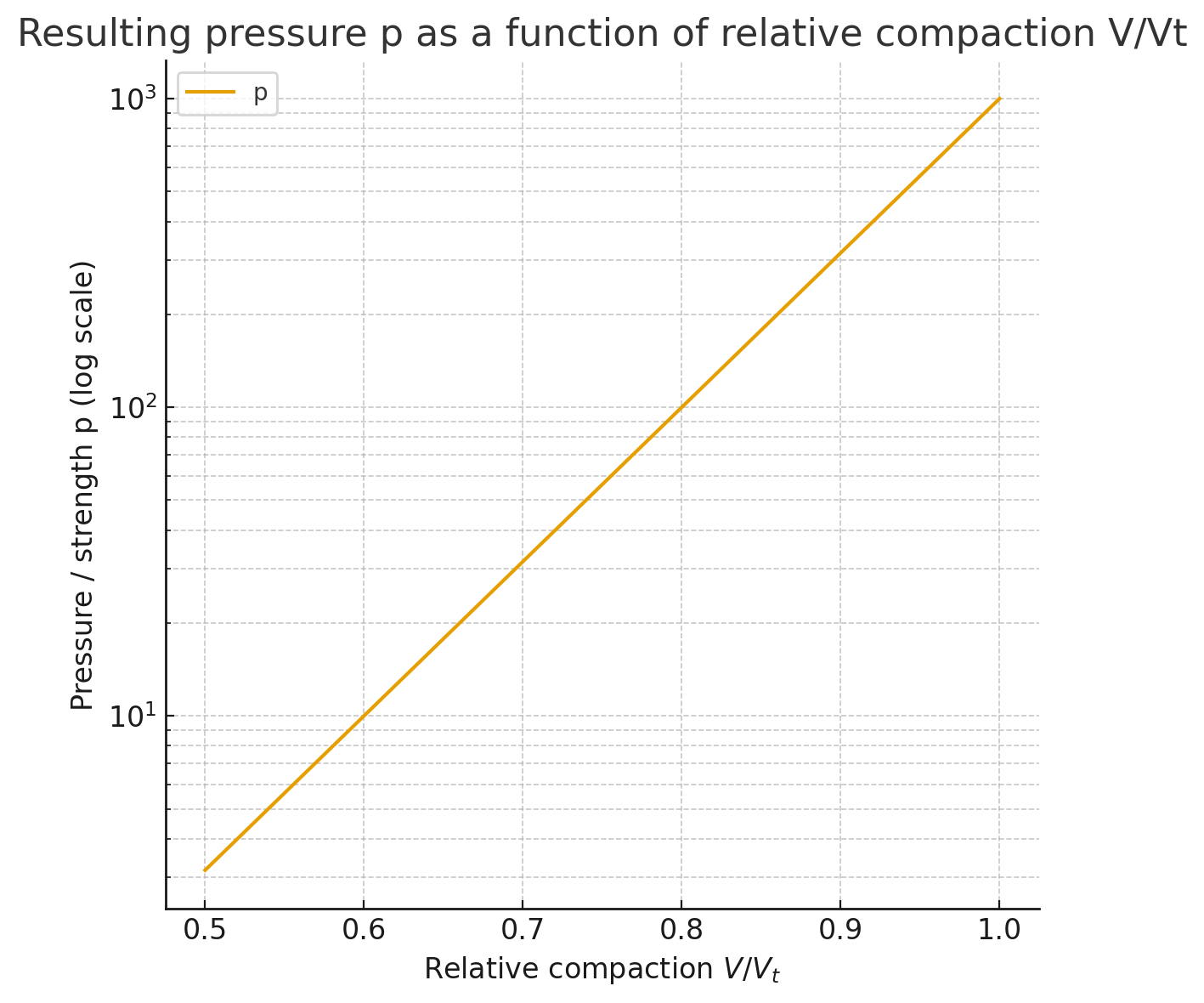

log p = C ⋅ (Vt ⋅ V) + K

V/Vt stands for the relative compaction, p for the pressure or strength. C and K are empirical constants. They can be determined from laboratory tests. If log p is plotted against V/Vt, the result is a straight line. From this follows: The pressure increases exponentially with increasing compression. The formula is not a physically based derivation but merely constructed phenomenologically from the dimensional analysis. This method can be used to roughly estimate how much powder needs to be compressed in order to obtain a more or less stable compressed material.

From the above equation, it can be deduced that the more energy is added to a powder during the mixing process, the more it is compacted. The amount of power/rotational speed of the mixing tool is also of great importance.