KoneSlid® mixer for the formulation of active ingredients using the example of pesticides

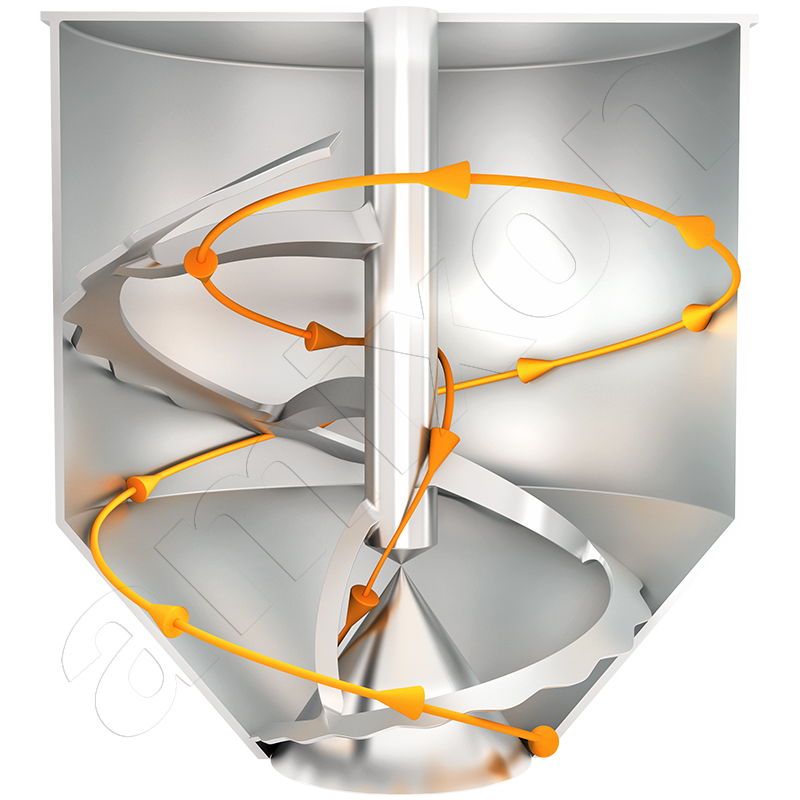

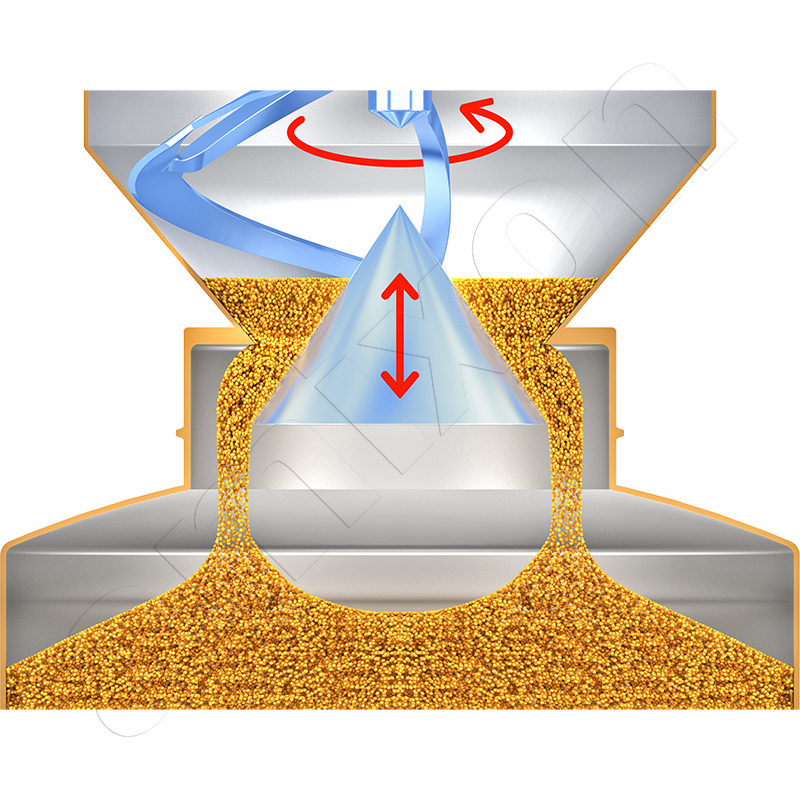

Homogenization and formulation of large volume flows is done with small mixers.

Active ingredient chemicals are particularly valuable when they are derived from a multi-step synthesis process. In most cases, the active ingredient is obtained in powder form as a high-concentrate. This ensures a long shelf life and allows for cost-effective packaging, transport and storage.

Highly concentrated chemical agents may show toxic properties. For this reason, a so-called "formulation" is carried out before the goods are released into circulation. Active ingredients are combined and blended with powdered carriers. For example, rock flour or kaolin can be used. In some cases, the mixture is even tableted, prilled, extruded or otherwise agglomerated. The active ingredient is then evenly distributed in the carrier substance. It is largely dust-free and free-flowing. It can be used in a similar way to a fast-dissolving instant drink. The active substance can be used safely in this preparation form. The end user can conveniently portion it before dissolving it in water. Crop protection agents are often applied in liquid form.

KoneSlid® mixers from amixon® are beneficially used for active ingredient formulation.

They are permanently gas-tight and quickly deliver ideal mixing qualities that cannot be improved in practice.

- ideal mixing qualities and microfine deagglomeration, dispersing

- extremely short mixing times, optionally with low or high energy input

- agglomerated powders are not crushed

- high degree of residual discharge, almost completely

- Filling levels can vary from approx. 10% to 100%

- Exemplary hygienic equipment design with regard to safe cleaning: either damp, wet or dry, manual or automatic

- gas-tight design, also suitable for overpressure if nitrogen overlay is required

- ATEX conformity mixing room zone 20, optionally also solvent explosion protection

- compact, space-saving design

- KoneSlid® mixers are built from 400 liters to 3000 liters capacity, adaptable to your requirements in 100 liter steps

- amixon® manufactures each mixer as a unique piece, specially designed to meet the customer's needs.

They are permanently gas-tight and quickly deliver ideal mixing qualities that cannot be improved in practice.

- ideal mixing qualities and microfine deagglomeration, dispersing

- extremely short mixing times, optionally with low or high energy input

- agglomerated powders are not crushed

- high degree of residual discharge, almost completely

- Filling levels can vary from approx. 10% to 100%

- Exemplary hygienic equipment design with regard to safe cleaning: either damp, wet or dry, manual or automatic

- gas-tight design, also suitable for overpressure if nitrogen overlay is required

- ATEX conformity mixing room zone 20, optionally also solvent explosion protection

- compact, space-saving design

- KoneSlid® mixers are built from 400 liters to 3000 liters capacity, adaptable to your requirements in 100 liter steps

- amixon® manufactures each mixer as a unique piece, specially designed to meet the customer's needs.

The main arguments supporting the use of KoneSlid® mixers are:

- Extremely fast and ideal complete discharge. The rotationally symmetrical cone element lowers and allows total discharge within a few seconds. This makes it possible to homogenize large volume flows with small mixers.

- The main mixing tool is only mounted and driven at the top. The shaft seal is almost maintenance-free.

- Despite the low rotational frequencies of the mixing tools, ideal mixing quality is achieved within just 20 to 60 seconds.

- KoneSlid® mixers are equipped with very large inspection doors. Optionally one or two at the mixing chamber and optionally one at the filling spout and discharge spout. They are manufactured using the Clever-Cut® process. The OmgaSeal® seal is unique in terms of hygiene and lifetime.

- Extremely fast and ideal complete discharge. The rotationally symmetrical cone element lowers and allows total discharge within a few seconds. This makes it possible to homogenize large volume flows with small mixers.

- The main mixing tool is only mounted and driven at the top. The shaft seal is almost maintenance-free.

- Despite the low rotational frequencies of the mixing tools, ideal mixing quality is achieved within just 20 to 60 seconds.

- KoneSlid® mixers are equipped with very large inspection doors. Optionally one or two at the mixing chamber and optionally one at the filling spout and discharge spout. They are manufactured using the Clever-Cut® process. The OmgaSeal® seal is unique in terms of hygiene and lifetime.

© Copyright by amixon GmbH