Baby food must be healthy and one hundred percent pure.

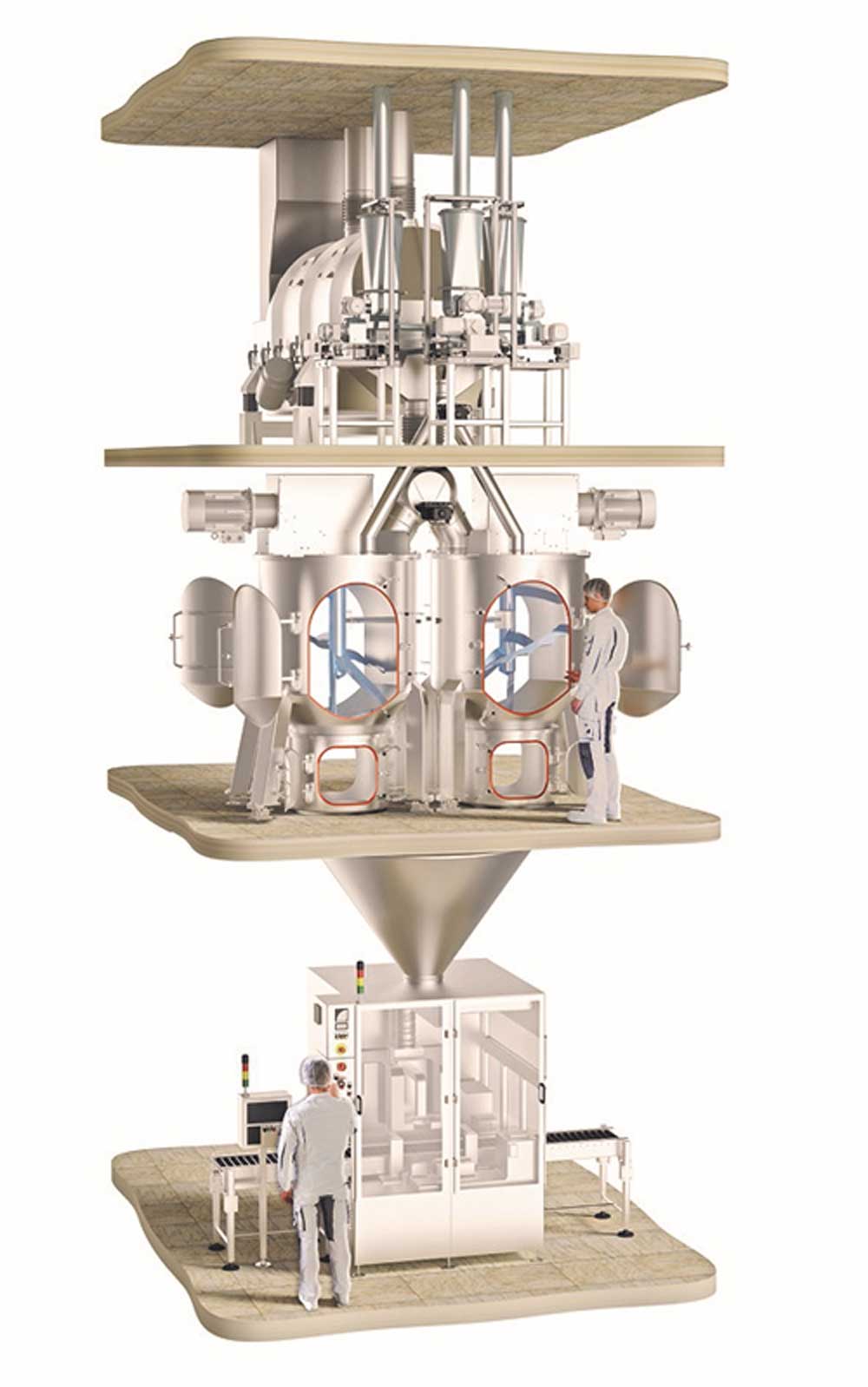

Precision mixer type KS with many inspections doors free of dead space; discharge of the mixing goods up to 100%, very fast and without segregation

Producers of infant formula bear a great responsibility. Baby food must be healthy and one hundred percent pure. These high quality demands are only met if the raw material components are prepared in quality-controlled systems. In the manufacturing process for dietetic foodstuffs, precision mixers are always involved for the admixing of trace elements and vitamins. This process must be carried out with high precision where the dosage and the mixing quality are concerned. Withthese requirements in view, amixon® has developed an interesting innovation: a single-shaft mixing system with comparatively small dimensions. This precision mixer is characterised by particularly short mixing and discharging times, amongst other things. It is thus capable of processing large product quantities in a short cycle time. Ideal mixing qualities and excellent particle protection are achieved in a new way.

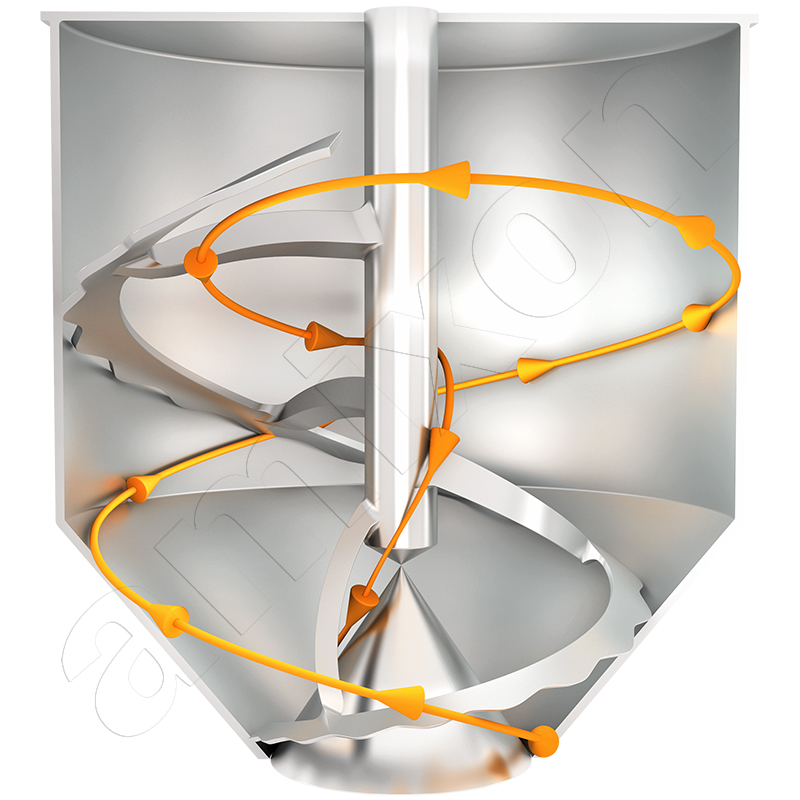

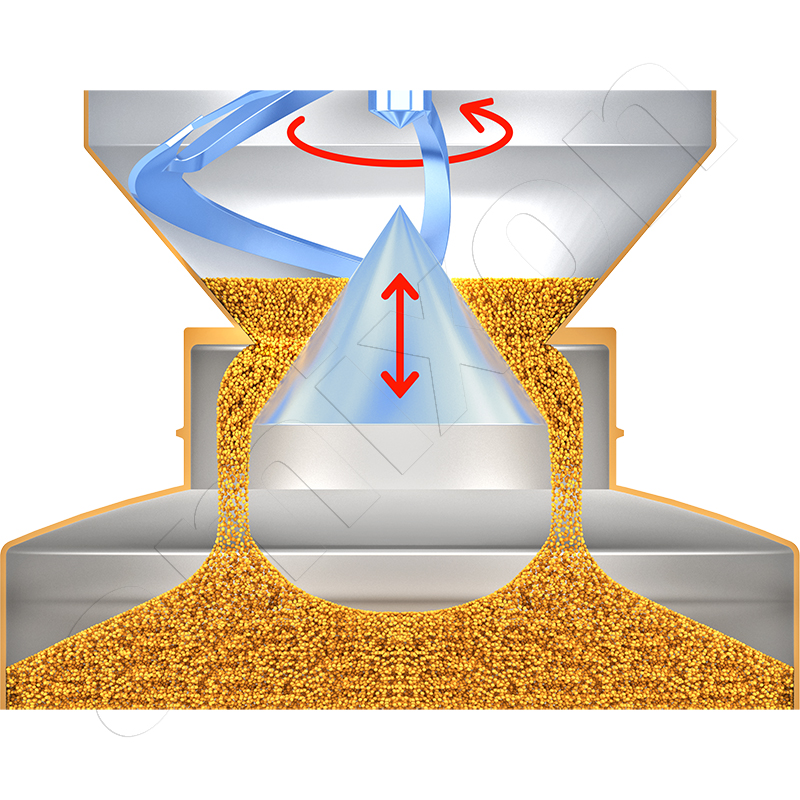

The mixing container consists of a silo-like container in whose centre a large cone is inserted at the bottom. It has a smooth, streamlined design and supports the flow process of the mixtures. Helical mixing tools convey the goods upwards in a spiral-like motion. This process takes place along the wall of the container. Having arrived at the top, the goods slide downwards and are directed to the outside once again by the cone. The homogenisation process takes place in the marginal area between the upward screwing and the downward movement. This process is gentle and effective. After approximately 20 to 30 revolutions an ideal mixing quality is obtained that cannot be further improved in practice. The displacer then lowers itself by a few centimetres, so that the emptying takes place quickly, off-centre and segregation-free. The mixer discharges up to 100%.

amixon® guarantees highest hygiene standards

Producers of industrially manufactured baby food made from dried milk derivatives have a great responsibility. Baby food must be healthy and one hundred percent pure. These high quality demands are only met if the raw material components are prepared in process-safe systems. Adequate powder mixing with innovative powder mixers is crucial to quality.

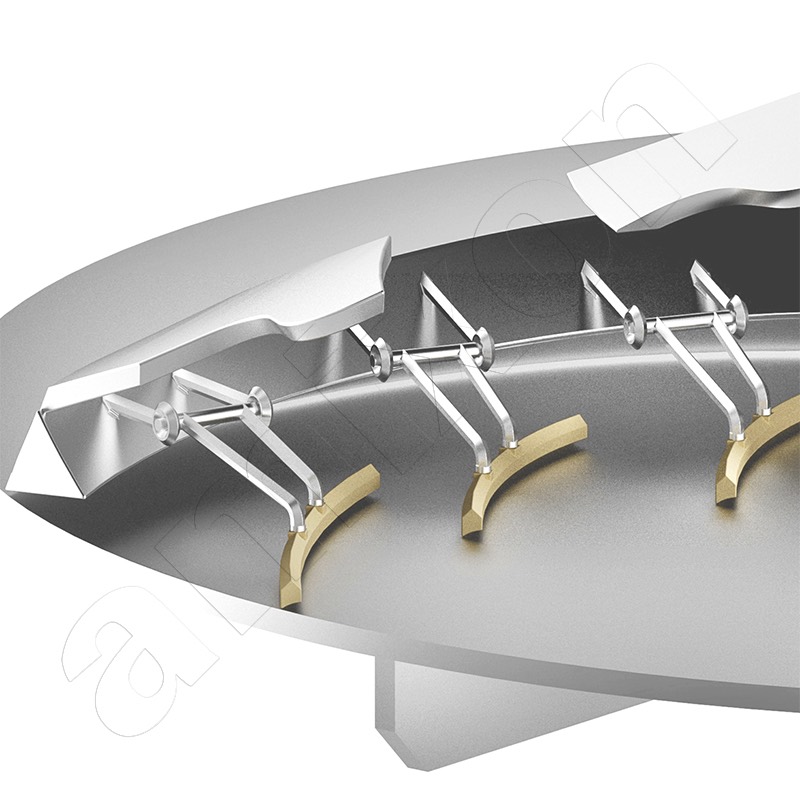

So-called triturations are premixes in which trace elements such as chromium, iron, fluorine, iodine, potassium, calcium, copper, magnesium, sodium, phosphorus, selenium and zinc are involved as microadditives. These must be absolutely free of agglomerates. High shear blades deagglomerate reliably and gently. The amixon® single-shaft mixer can fill and empty itself automatically with the contents of standard drums. It operates dust-free and ensures the preparation of homogeneous premixes.

Twin shaft mixer for large batches

If the baby food is to be homogenised in large batches, amixon® recommends the use of the HM twin-shaft mixer.

Nutrient manufacturers pay the utmost attention to the topic of "cleaning". amixon® offers various cleaning systems and has several cleaning concepts: Dry, moist or wet cleaning can be selected.

© Copyright by amixon GmbH