Helix mixing tools

Helix mixing tools are also referred to as screw ribbon or spiral mixing tools. A commonly used term is ‘ribbon blender’. A ribbon blender is usually a screw mixer for powdery goods. However, its screw ribbon rotates around a horizontal axis. Such mixers are only partially classified as precision mixers.

Their mixing performance is hardly comparable to that of vertical helix mixers.

Vertical ribbon blenders, helix mixers, screw ribbon mixers or spiral mixers, on the other hand, are capable of mixing powdery component compositions in a ratio of 1:100,000 in a technically ideal manner. (Mixing quality variation coefficient below 5%).

In special cases, such mixers also have spirals whose axis of rotation is inclined by up to 30°. Hollow sphere mixers also belong to this category. Precision mixers produce technically ideal mixing qualities even when the solids are moistened or suspended. The mixing chamber typically consists of a closed, vertically standing container.

This must be rotationally symmetrical in the form of a sphere, cylinder or cone. Inside the mixing chamber is the helical mixing tool, which is mounted in the axis of symmetry of the mixing chamber.

In amixon® mixers, the mixing tool is mounted exclusively at the top; there is neither a shaft feed-through nor a bearing point at the bottom. The mixing tool never comes into contact with the mixing chamber.

Filling takes place from above and emptying from below. Appropriate fittings and valves are provided for this purpose. The bottom closure valve must be flush with the bottom. This ensures that the mixer mixes without dead space when the valve is closed.

In addition to the classic helix geometry, amixon® also manufactures the special SinConvex® and SinConcave® mixing helix designs. These special designs improve mixing efficiency, especially for difficult-to-mix material systems, while also promoting the self-emptying effect of the mixer. This reduces product residues to a minimum and facilitates cleaning of the mixing chamber.

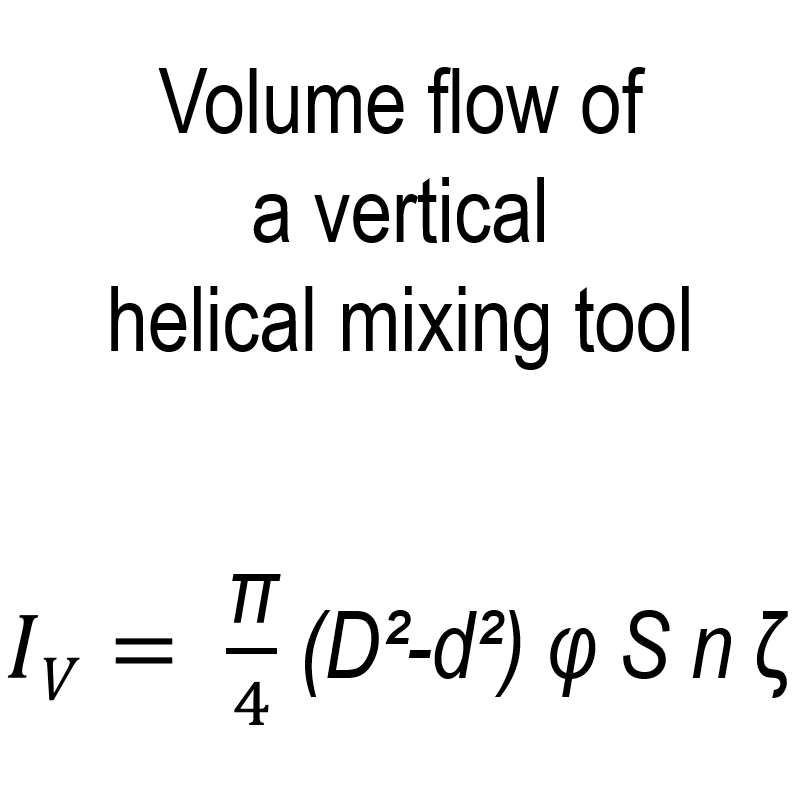

The axial conveying capacity of a helix mixing tool can be calculated approximately using the following formula:

IV=π/4⋅(D2−d2)⋅φ⋅S⋅n⋅ζ

IV: Conveying volume flow

π: Circle constant

D: Outer diameter of the mixing helix

d: Inner diameter of the mixing helix

φ: Filling degree (dimensionless value between 0 and 1)

S: Pitch of the helix

n: Rotational frequency of the helix

ζ: Speed coefficient (dimensionless, based on experience)

The formula describes the theoretical flow rate per unit of time that a helical mixing tool can move upwards within the rotationally symmetrical mixing chamber.