Boiler flow

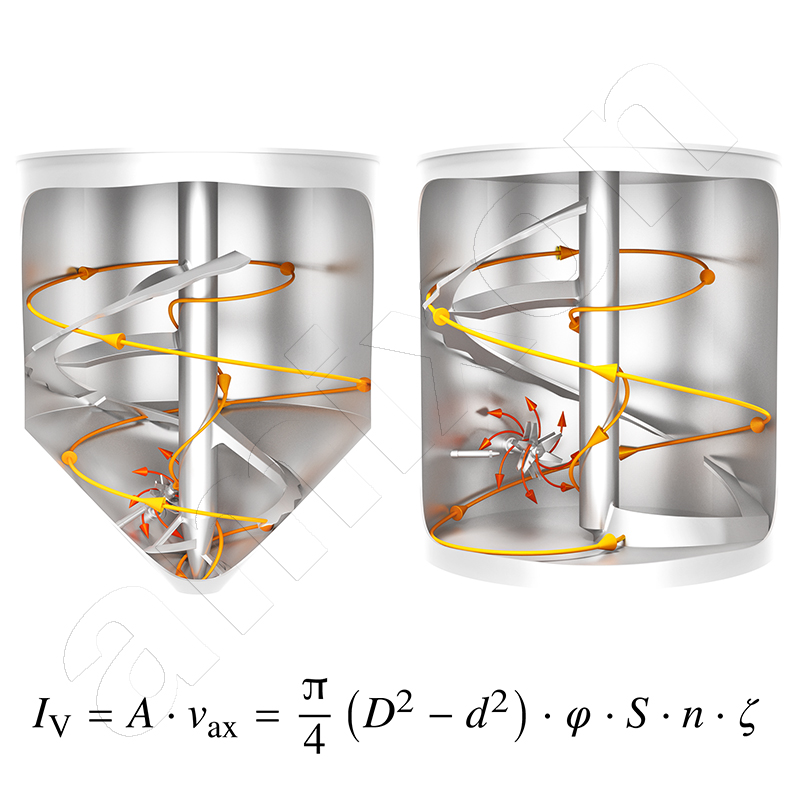

An amixon® powder mixer generates a characteristic bowl flow. The mixing tool is a helix. It can have a sinConvexe® or a SinConcave® design. It moves the bulk material spirally upwards along the bowl wall. From the top, the mix flows back inwards and sinks again in the centre of the vessel. This creates a three-dimensional, toroidal main flow that covers the entire mixing chamber.

This macroscopic circulation flow is supplemented by localised turbulence and relative movements of the particles. This creates secondary flows that produce additional effects. Each particle passes through all zones of the mixing chamber at recurring intervals.

This means for continuous operation as a boiler flow mixer:

- A state of almost ideal mixing is achieved in the boiler.

- Components introduced in defined mass proportions are immediately added to the circulating mix.

- Immediate homogenisation is ensured by the permanent main flow.

- The composition of the discharge flow always corresponds to the mixing quality in the boiler.

The amixon® vessel flow therefore differs significantly from the plug flow in the tube mixer. While the "first in - first out" principle applies in the pipe, the flow in the amixon® powder mixer is characterised by complete mixing. The residence times of the individual particles are different, but the overall mixture remains stable and homogeneous.

From a scientific point of view, the flow and mixing behaviour can be described well using the Continuous Stirred Tank Reactor (CSTR) model. This model assumes ideal mixing of the reaction or mixing volume. This is exactly what is realised in amixon® powder mixers through the large-volume circulation flow and the intensive but particle-friendly relative movement.