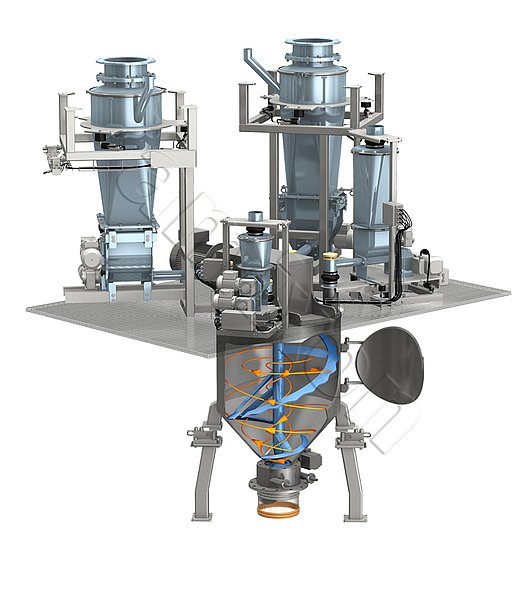

Small size, big benefits

amixon® continuous mixers for the streamlined, compact handling of dry ingredients

Compared with standard batch mixers, amixon® Continuous Mixers can offer numerous advantages for your product quality and manufacturing efficiency. Used across diverse industries from food to chemicals to pharmaceuticals, AMK Continuous Mixers are a tremendous asset for high-volume, single-product applications:

- Streamlined system – Weighing, charging, mixing, and discharging all take place simultaneously within a single, compact device.

- High outputs in record time – Continuously mix large quantities with no downtime between charges.

- Consistent, automatable mixing performance – Achieve uniform product quality with minimal labor and oversight.

Steady processes built at scale

amixon® Continuous Mixers are tailored to your specific dry ingredients and product standards so that you can achieve consistently ideal blends.

- Adjustable mixing intensities – From gentle homogenization to intensive deagglomeration

- Eliminate product loss and segregation – The patented SinConvex® mixing tool accomplishes 99.997% discharge

- Multi-functional capabilities – Can alternate between batch and continuous mixing

- Extended processing options – Capable of moistening, tempering, drying, and reaction processing

Mixing made simpler

Engineered in Paderborn, Germany, amixon® Continuous Mixers are outfitted with cutting-edge features and thoughtful details to boost production output and reduce overhead.

- Easy cleaning and drying – Fully accessible mixing chamber dramatically reduces cleaning and drying times between recipes

- Compliance on a global scale – Can be manufactured for compliance with FDA, EHEDG, GMP, 3-A Sanitary Standards, and USDA regulations

- Ideal for product development and testing – Requires a fraction of the resources necessary for analyzing batch mixtures