Which powder mixer can mix bulk materials gently?

Question from a customer: "Is there an ideal mixer/ blender for my application?"

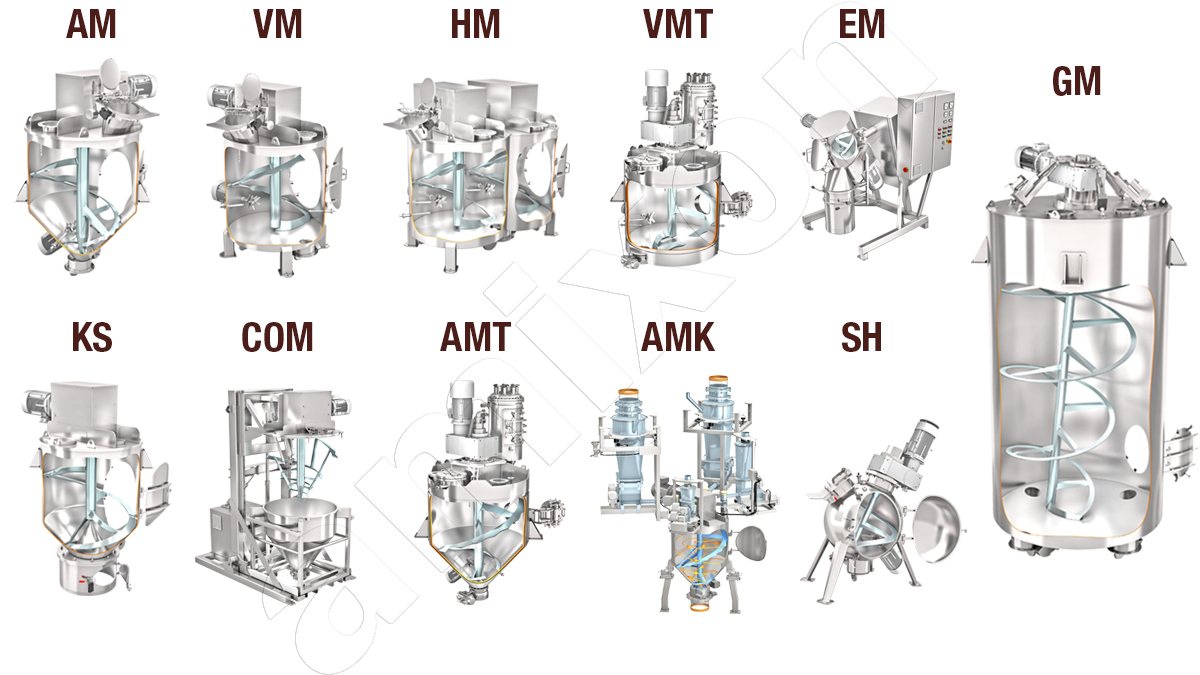

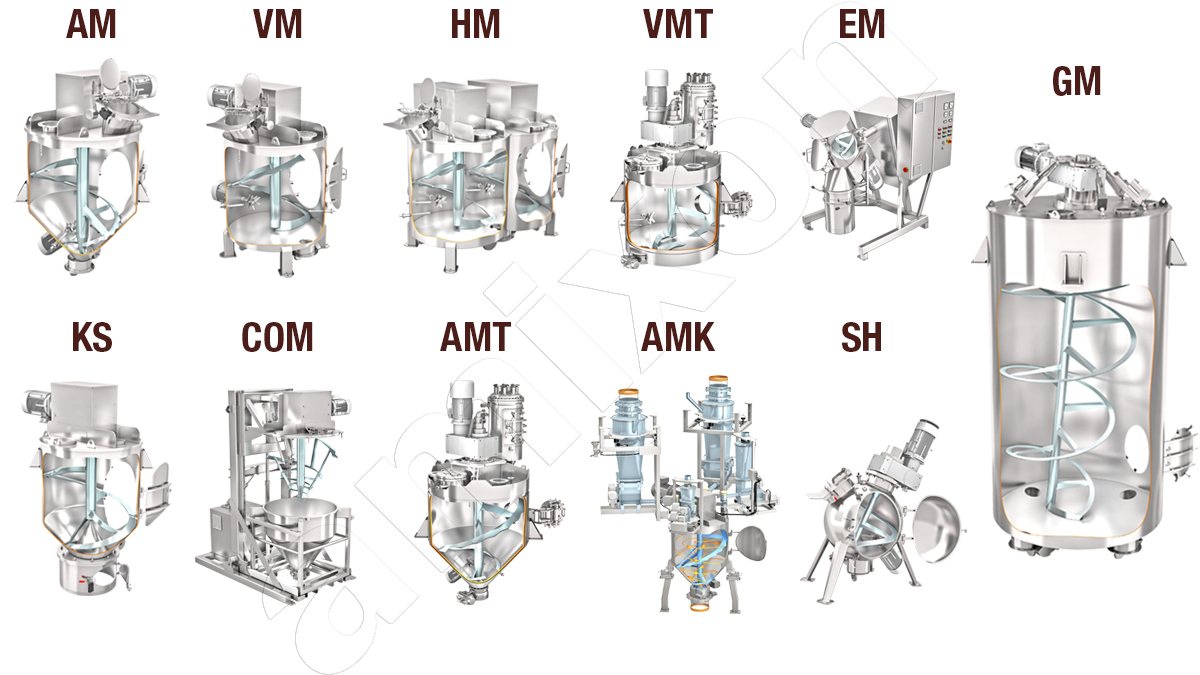

The amixon® product programme is uniquely comprehensive and particularly sophisticated. This enables amixon® to meet the requirements of various industries. amixon®'s experience is based on 40 years of tradition. Within the sectors, the processing stages for bulk goods are more or less specified. amixon® has also created outstanding solutions for this.

The amixon® production programme is based on the "vertical philosophy". This means that the mixer shafts are arranged vertically. In special cases, they can also be inclined by up to 20°.

Vertical mixers/ blenders have many advantages:

- they produce ideal mixing qualities that can no longer be improved in practice

- they work largely independently of the filling level

- they have very good residual emptying properties

- They are particularly robust and designed for a long service life. Even 40 years is not uncommon

- they are particularly low-maintenance - many years even maintenance-free

- they are hygienically designed

- they have large inspection doors

- There is only one shaft feed-through and this is located above the mix. This upper shaft seal is practically maintenance-free

Question from a customer to amixon®: Which mixer/ blender do you recommend if my powders are very sensitive, such as muesli?

Oatmeal, flakes or agglomerated instant powders can be affected by abrasion and breakage!

Hardly any other bulk material is as heterogeneous as a muesli mix. Oat flakes are the most sensitive. They break at the slightest load and create dust when they are moved together. The dust settles on the particles of the other components and makes them look less fresh.

Other coarse-grained components have very different bulk densities. Freeze-dried berries, bananas, puffed extrudates or crumbs, for example, are very light. They tend to float upwards in the fill. This leads to unwanted segregation.

Large cornflakes are heavier, hard and even somewhat elastic, but they also break quickly when they are in a mixture.

Treated seeds have an even higher bulk density. They tend to sink to the bottom, causing undesirable segregation.

Sultanas are even heavier and tend to clump together due to their stickiness.

amixon® has an excellent solution to these challenges in the form of the high-performance twin-shaft mixer/ blender. The mixer shown here can mix 2 m³ batches and only needs 15 seconds to achieve the ideal mixing quality for the 2 m³ batch. The energy input of the mixing tools during the short mixing time is so low that practically no particle destruction takes place in the muesli.

The above example is representative of other complex mixed tasks: Instant soups and sauces, breadcrumb mixes, dessert mixes, baking mixes, tea and herb mixes, ...

Oatmeal, flakes or agglomerated instant powders can be affected by abrasion and breakage!

Hardly any other bulk material is as heterogeneous as a muesli mix. Oat flakes are the most sensitive. They break at the slightest load and create dust when they are moved together. The dust settles on the particles of the other components and makes them look less fresh.

Other coarse-grained components have very different bulk densities. Freeze-dried berries, bananas, puffed extrudates or crumbs, for example, are very light. They tend to float upwards in the fill. This leads to unwanted segregation.

Large cornflakes are heavier, hard and even somewhat elastic, but they also break quickly when they are in a mixture.

Treated seeds have an even higher bulk density. They tend to sink to the bottom, causing undesirable segregation.

Sultanas are even heavier and tend to clump together due to their stickiness.

amixon® has an excellent solution to these challenges in the form of the high-performance twin-shaft mixer/ blender. The mixer shown here can mix 2 m³ batches and only needs 15 seconds to achieve the ideal mixing quality for the 2 m³ batch. The energy input of the mixing tools during the short mixing time is so low that practically no particle destruction takes place in the muesli.

The above example is representative of other complex mixed tasks: Instant soups and sauces, breadcrumb mixes, dessert mixes, baking mixes, tea and herb mixes, ...

Question from a customer to amixon®: When it comes to the gentle mixing/ blending of bulk materials, amixon® also recommends the Gyraton® Mixer?

Why was the Gyraton® mixer / blender developed by amixon® in the first place when the twin-shaft mixer and the KoneSlid® mixer/ blender already exist?

The main difference lies in the way they work.

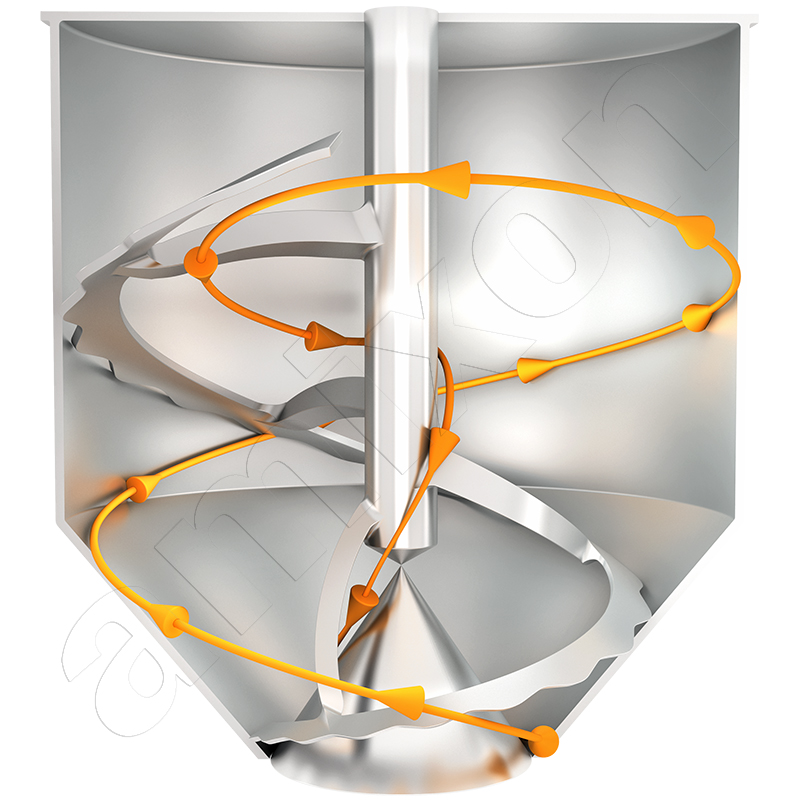

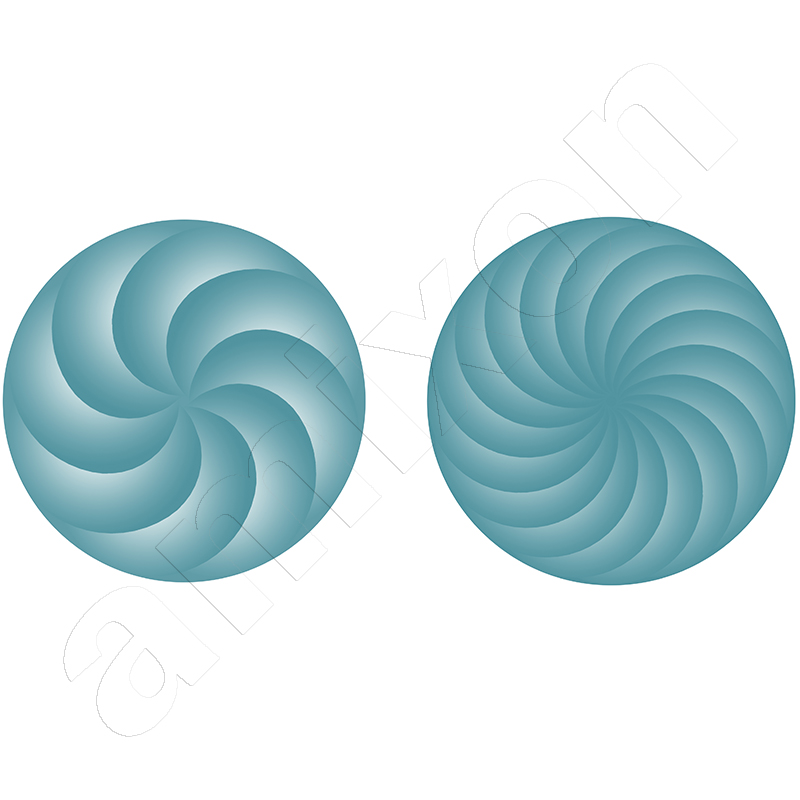

The amixon® twin-shaft mixer/ blender is designed for short mixing times and minimised energy input. Its batch size is rarely more than 15 m³. The two helix mixing tools, which rotate in the same direction, produce complete mixing despite the low rotation frequency. After four to five revolutions, the mix is completely circulated once.

The KoneSlid® mixer/ blender is designed for smaller batches (400 litres to 3000 litres). It mixes just as quickly and gently as the twin-shaft mixer. The main speciality is the conical closure system. Free-flowing mixes are completely discharged in just a few seconds.

The Gyraton® mixer/ blender is designed for large batches of up to 70 m³ and requires very small drive motors. The mixing tool rotates slowly. The mixing tool is moved along the cylinder wall at a defined distance from the cylinder wall without any dead space. The mixing time can be adjusted depending on the motor power and speed. This large-capacity mixer is particularly compact and also fulfils the highest hygiene requirements. The mixing concept is very economical, as the electrical connected load is low.

Why was the Gyraton® mixer / blender developed by amixon® in the first place when the twin-shaft mixer and the KoneSlid® mixer/ blender already exist?

The main difference lies in the way they work.

The amixon® twin-shaft mixer/ blender is designed for short mixing times and minimised energy input. Its batch size is rarely more than 15 m³. The two helix mixing tools, which rotate in the same direction, produce complete mixing despite the low rotation frequency. After four to five revolutions, the mix is completely circulated once.

The KoneSlid® mixer/ blender is designed for smaller batches (400 litres to 3000 litres). It mixes just as quickly and gently as the twin-shaft mixer. The main speciality is the conical closure system. Free-flowing mixes are completely discharged in just a few seconds.

The Gyraton® mixer/ blender is designed for large batches of up to 70 m³ and requires very small drive motors. The mixing tool rotates slowly. The mixing tool is moved along the cylinder wall at a defined distance from the cylinder wall without any dead space. The mixing time can be adjusted depending on the motor power and speed. This large-capacity mixer is particularly compact and also fulfils the highest hygiene requirements. The mixing concept is very economical, as the electrical connected load is low.

Question from a customer to amixon®: What type of bulk materials was the Gyraton® mixer/ blender developed for?

Bulk goods such as tea, herbs, coffee, spices, tobacco, food for livestock or chemical raw materials, rare earths, ores, metal breeze, metal powder, plastics or stabilisers are delivered from overseas.

It must be assumed that the delivered goods contain inhomogeneities: Examples are Grain sizes, bulk densities, content of valuable substances, moisture content, colour and taste properties, etc.

Other bulk materials such as battery masses, carbon masses, metal casting, battery masses, high-performance ceramics or nanostructured goods are processed in small batches. They also have to be homogenised in large batches in order to obtain a homogeneous end product.

Example: Mobile phones, Electrical capacitors are made from doped nonceramics. These are produced in batches of 50 litres each. The final large batch of 25 m³ must ensure that the capacitors for several tens of thousands of mobile phones have the same properties.

Example of homogeneity verification for a large quantity of powder:

It is only possible to determine the quality of large quantities of bulk material if

- a large number of samples are taken and analysed or

- the total mass is first homogenised and then a sample is taken.

Sampling and statistical analyses can be expensive. In such cases, the Gyraton® mixer can provide valuable services.

Bulk goods such as tea, herbs, coffee, spices, tobacco, food for livestock or chemical raw materials, rare earths, ores, metal breeze, metal powder, plastics or stabilisers are delivered from overseas.

It must be assumed that the delivered goods contain inhomogeneities: Examples are Grain sizes, bulk densities, content of valuable substances, moisture content, colour and taste properties, etc.

Other bulk materials such as battery masses, carbon masses, metal casting, battery masses, high-performance ceramics or nanostructured goods are processed in small batches. They also have to be homogenised in large batches in order to obtain a homogeneous end product.

Example: Mobile phones, Electrical capacitors are made from doped nonceramics. These are produced in batches of 50 litres each. The final large batch of 25 m³ must ensure that the capacitors for several tens of thousands of mobile phones have the same properties.

Example of homogeneity verification for a large quantity of powder:

It is only possible to determine the quality of large quantities of bulk material if

- a large number of samples are taken and analysed or

- the total mass is first homogenised and then a sample is taken.

Sampling and statistical analyses can be expensive. In such cases, the Gyraton® mixer can provide valuable services.

The amixon® product portfolio is unique in its completeness.

amixon® thus emphasises its global quality and innovation leadership in vertical mixers / blenders for dry, moist or wet bulk solid materials.

amixon® thus emphasises its global quality and innovation leadership in vertical mixers / blenders for dry, moist or wet bulk solid materials.

© Copyright by amixon GmbH