Pulvermischer und Sterilapparate für Lebensmittel und Stabilisatoren

Pulvrige Stabilisatoren sind kompakt, leicht dosierbar und deutlich länger haltbar als ihre flüssigen Pendants. Sie lassen sich automatisiert verarbeiten, sofern sie staubarm sind und gut fließen. Ihre Rheologie muss prozesssicher sein. Genau hier setzt amixon® an. Unsere Präzisionsmischer optimieren die Fließeigenschaften selbst schwierigster Pulver und erzeugen absolut homogene Mischungen ohne Staubentwicklung. Dabei bleibt die Partikelstruktur erhalten..

Auf Wunsch können amixon®-Sterilapparate pulvrige Güter sterilisieren und unter Vakuum trocknen – hygienisch, schonend und effizient.

Die amixon®-Mischer basieren auf eigenen Patenten.

- Sie verarbeiten große und kleine Chargen präzise, schnell und rückstandsfrei.

- Selbst bei einer Chargengröße von 100 m³ erzielen Gyraton®-Mischsilos eine ideale Homogenität – und das bei erstaunlich geringer Antriebsleistung.

- Sie mischen besonders schonend.

- Sie mischen intensiv desagglomerierend.

- Sie verbessern die Rieselfähigkeit, was für automatisierte Abfüllprozesse von Vorteil ist.

- Mischer von amixon® verbessern das Instantverhalten pulvriger Stabilisatoren. Dies ist von entscheidender Bedeutung, wenn diese später in einem High-Shear-Flüssigmischer dispergiert oder gelöst werden sollen.

- Sie können pulvrige Stabilisatoren agglomerieren.

- Sie reinigen sich selbsttätig – trocken oder nass.

- Sie erfüllen höchste Hygienestandards

- - teilweis oberhalb der EHEDG-Standards

amixon®-Mischer. Das bedeutet: Made in Germany – individuell konstruiert und exakt auf Ihre Produkte abgestimmt. amixon® steht für hygienische und verfahrenstechnisch überlegene Lösungen in der Lebensmittelproduktion.

Die amixon®-Mischer erfüllen höchste Hygienestandards für Lebensmittelsicherheit

amixon® Mischanlagen erfüllen höchste Anforderungen an Lebensmittelsicherheit. Sie entsprechen den Richtlinien und Zertifizierungen wie 3-A, EHEDG, FDA, USDA, ATEX und GMP. Doch Hygiene ist für amixon® mehr als nur Vorschrift. Sie ist integraler Bestandteil unserer Konstruktion. Das hygienische Design ist konsequent durchdacht – totraumfrei, leicht zu reinigen, validierbar.

Unsere OmgaSeal®-Inspektionstüren sind spaltfrei und dauerhaft gasdicht. Große Ausführungen ermöglichen einen ergonomischen Zugang zum Mischraum. OmgaSeal®gestattet Washing in place (WIP) und eine sichere Trocknung..

Das geneigte SinConvex Mischwerkzeug verhindert die Ansammlung von Rückständen. Die Entleerleistung wird erhöht – bei frei fließenden Gütern bis zu 99,997%. Die Reinigung wird vereinfacht.

Die vertikal montierten Mischwerkswelle ist nur von oben abgedichtet, wodurch der Kontakt zwischen der Dichtung und den Schüttgütern ausgeschlossen ist.

In Testzentren in Deutschland, den Vereinigten Staaten, Indien, Thailand, Südkorea und Japan arbeiten unsere Ingenieure mit Ihnen zusammen, um für Ihr Produkt und Ihre Anforderungen maßgeschneiderte Mischanlagen zu entwickeln

amixon® Pulvermischer für trockene, feuchte und flüssige Substanzen

amixon® Mischanlagen sind für nahezu alle industriellen Mischaufgaben in der Lebensmittelindustrie geeignet. amixon® Mischer machen Ihren Mischbetrieb noch profitabler: Mischen auf höchstem verfahrenstechnischem Niveau. Variable Füllgrade von 5% bis 100%. Im selben Mischer homogenisieren Sie extrem schonend oder aggressiv desagglomerierend. Höchst möglicher Hygienestandard a) für die Trockenreinigung b) für die Nassreinigung c) wahlweise vollautomatisch. Ergonomische Bauart. Lebenslanger amixon® Exzellenz Service.

Sei es die intensive Deagglomeration, die schonende Homogenisierung, oder die Aufbaugranulierung und Vakuumtrocknung bei niedriger Temperatur: amixon® Mischanlagen sind für viele Anwendungen in der Lebensmittelindustrie geeignet und ein wichtiger Baustein für Ihren Erfolg:

Instantsuppen und -soßen

Komplexe Rezepturen, bestehend aus unterschiedlich großen, pulverförmigen Komponenten wie schonend getrocknetem Gemüse, Gewürzen, Extrakten, Stabilisatoren und Enzymen, werden ohne Entmischung oder Partikelgrößenreduzierung gleichmäßig und produktschonend gemischt. Die anschließende Verpackung erfolgt unter Inertbedingungen, um Aroma, Farbe und Funktionalität der Zutaten optimal zu bewahren.

Industrielle Backmischungen

Im Mischer werden Fette, Öle, Backextrakte, Lecithine und Aromen gleichmäßig in die pulverförmigen Zutaten eingearbeitet. Dabei erfolgt eine homogene Benetzung der Mischung ohne Klumpenbildung oder Anhaftungen. Das Produkt bleibt kühl, rieselfähig und über lange Zeit lagerstabil.

.

Gewürz-, Kräuter- und Gewürzmischungen

Frische Kräuter und Gewürze werden getrocknet, entkeimt und gemahlen. Dabei sollen sie ihre ätherischen Öle bewahren. Anschließend werden sie im amixon®-Mischer schonend und homogen mit anderen Zutaten (fest oder flüssig) veredelt. Oft werden fragile Zutaten wie Blüten, Blattstücke oder granulierte Extrudate hinzugefügt. Die Endprodukte sind locker, fließfähig und staubfrei. Sie können automatisch und komfortabel verpackt werden. Dabei verlieren sie ihre funktionalen Eigenschaften nicht. Unsere Mischer können auf verschiedene Weise sterilisiert werden. So sind sie keimfrei. amixon®-Sterilreaktoren können sogar zur Sterilisierung von Pulvermischungen, Tee, Kräutern oder Saaten eingesetzt werden.

Babynahrung, Säuglingsanfangsnahrung, Proteinpulver und Nahrungsergänzungsmittel

Besonders schonend werden lebende Bakterienkulturen wie Probiotika und andere mikrobiell aktive Stoffe in sprühgetrocknete oder agglomerierte Trägerstoffe eingemischt, ohne dass die Instanteigenschaften verloren gehen. Auch temperaturempfindliche Vitamine, Vitalstoffe und mikronisierte Teeblätter lassen sich im amixon®-Mischer homogen einmischen, ohne thermische oder mechanische Belastung – selbst bei Großchargen von bis zu 12 m³. amixon®-Mischer erfüllen höchste Hygienestandards.

Instantgetränke wie Kaffee, Tee, Vitamintabletten oder Vitaminsäfte

...... für all diese Produkte gilt ähnliches wie für Babynahrung und Nahrungsergänzungsmittel.

Weitere gängige Anwendungen sind unter anderem

- Große Chargen Schüttgut (bis 100m³) ideal genau homogenisieren

- Getreide bedampfen und sterilisieren

- Paniermehlveredelung

- Herstellung von Aufschlagsmassen mit Verdickungs- und Emulgiermittel

- Konditionierung von Saatgutmischungen, Milchpulver

- Müesli- und Cerialienaufbereitung

- Stärkeaufbereitung

- Süßungsmittel aus amixon®Fermentationsprozessen

- Verarbeitung von Fließhilfsmittel und

- Stabilisatoren

Mischanlagen für Lebensmittel

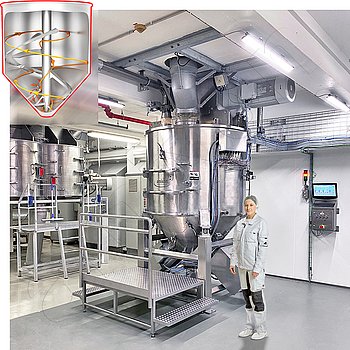

amixon® Konusmischer

Der Konus-Einwellenmischer von amixon® ist eine besonders vielseitige Mischmaschine für die Lebensmittelindustrie. Er eignet sich für trockene und feuchte Pulver ebenso wie für flüssige Suspensionen. Auch pastöse und teigige Mischgüter können verarbeitet und dosierend ausgetragen werden.

Das Wendel-Mischwerkzeug ist wahlweise in SinConvex®- oder SinConcave®-Ausführung erhältlich. In der Lebensmittelverarbeitung ist es entscheidend, dass die Produkteigenschaften erhalten bleiben. Partikelform und -größe sollen unverändert bleiben. Das Endprodukt soll gut fließen und möglichst staubfrei sein.

Der Konusmischer kann zudem Pulver desagglomerieren, einfärben, benetzen, agglomerieren und sogar trocknen. Er verarbeitet Chargen mit stark variierendem Volumen – von etwa 10 % bis 100 % des Nutzvolumens. Dabei erzielt er stets ideale Mischgüten und erfüllt höchste Hygieneanforderungen. Rieselfähige Schüttgüter können vollständig ausgetragen werden.

Gyraton®-Silomischer

Der Gyraton® ist ein vertikales Mischsilo für große Pulvermengen von bis zu 100 m³. Er ist platzsparend und kompakt gebaut. Er vereint Lagerbehälter und Hochleistungsmischer in einem Gerät. Der zentrale Mischwendel fördert das Schüttgut spiralig aufwärts. Durch die Schwerkraft fließt das Schüttgut abwärts. So entsteht ein langsamer, aber äußerst effizienter Gesamtproduktumsatz. Der Mischprozess erfolgt bei sehr geringer Antriebsleistung, selbst bei großen Volumina. Ein Mischsilo mit 50 m³ Volumen benötigt beispielsweise einen 30-kW-Motor.

Der Gyraton®-Mischer arbeitet besonders schonend. Er erzielt ideale Mischgüten selbst bei Komponetenzusammensetzungen von 1 zu 100.000, der Mischgüte-Variationskoeffizient ist kleiner als 5 %.

Die Partikelstruktur bleibt erhalten und die Partikelgrößen werden nicht verändert. Die Bauform ist totraumfrei, hygienegerecht und leicht zu reinigen. Auf Wunsch kann der Apparat mit automatischen Trocken- oder Nassreinigungssystemen ausgestattet werden.

KoneSlid®-Mischer KS

Der KoneSlid®-Mischer verarbeitet fragile und pulverförmige Zutaten besonders schonend und mit hoher technischer Präzision. Bereits nach 20 bis 30 Umdrehungen werden ideale Mischgüten erzielt. Diese besonders sanfte Mischwirkung ist entscheidend, wenn agglomerierte Sprühturmprodukte ihre Instanteigenschaften behalten sollen.

Der KoneSlid®-Mischer ist eine Weiterentwicklung des bewährten Konusmischers. Sein zentrales Element ist der Verschließ-Konus, dessen Spitze nach oben zeigt. Dieser dient zugleich als Misch- und Verschlussorgan. Die vom Wendelwerkzeug aufwärts geförderte Mischung strömt im Zentrum des Mischraums nach unten und wird vom inneren Konus nach außen geleitet. Aus diesem Strömungsprinzip leitet sich auch der Name „KoneSlid®” ab.

Der KoneSlid®ermöglicht extrem schnelle Mischtakte und eine vollständige Entleerung. Die Entleerung erfolgt innerhalb weniger Sekunden – schnell, sauber und produktschonend.

Er eignet sich besonders für sensible Produkte wie Säuglings- und Babynahrung sowie Instantgetränke. Auch bei der Veredelung von Panaden zeigt er seine Stärken.