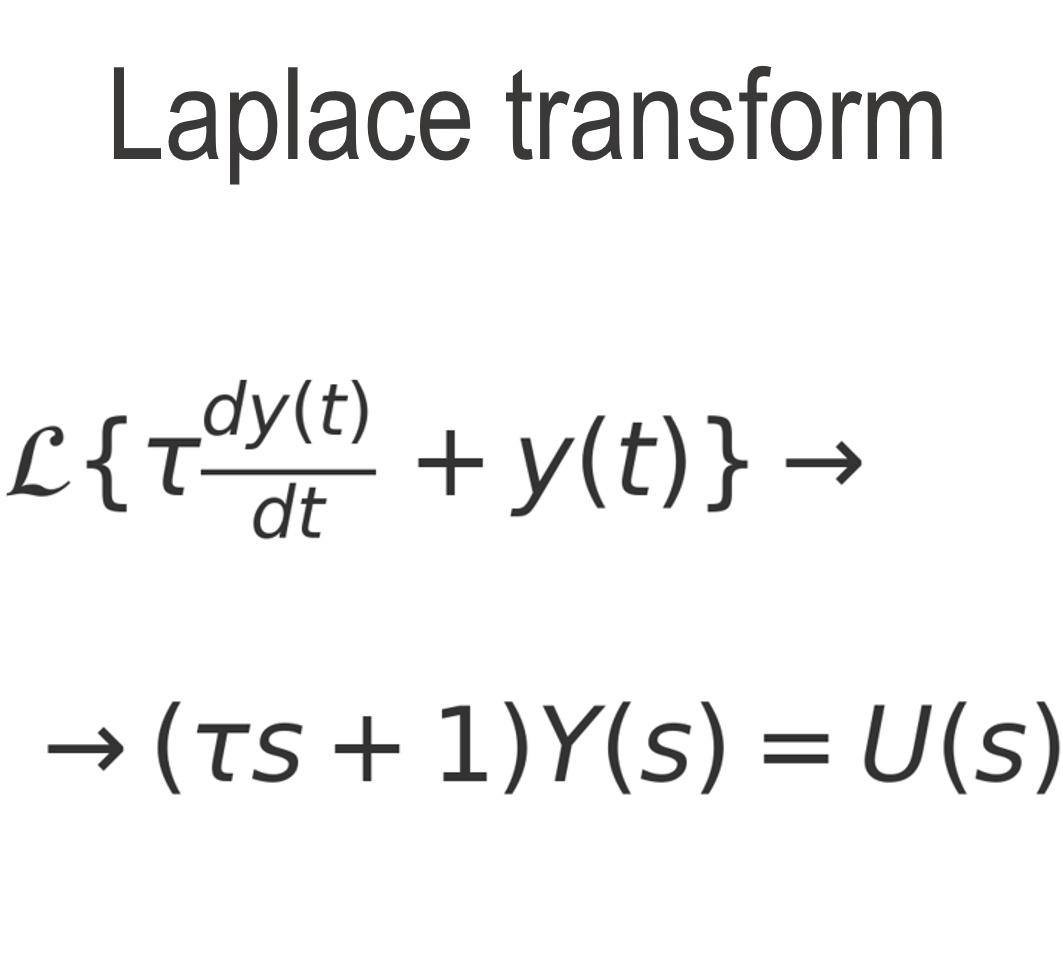

transformation of laplace

Exemplary application of the Laplace transformation for a continuous mixing process in the amixon® AMK 1000 mixer.

Powder A flows constantly into the mixer at a rate of 1,000 kg per hour, while powder B is fed in at a rate of 10 kg per hour. Initially, the mixing chamber is closed, but the mixing tool is already rotating. Previous mixing quality tests have shown that ideal mixing quality is achieved after 20 revolutions. The mixing tool rotates at 20 revolutions per minute. After the mixer has been filled with 700 kg, the discharge valve opens to such an extent that the sum of the incoming mass flows corresponds to the outgoing mass flow, i.e. 1010 kg per hour. This process runs smoothly. Now, suddenly, a malfunction occurs. The flow of component B is blocked for exactly 20 seconds. The dosing unit B is then corrected and component B flows into the mixer at double the rate (20 kg per hour) for 20 seconds. It then flows again at 10 kg per hour.

Before the malfunction occurred, the distribution was ideal. The coefficient of variation for the mixing quality was 3%.

The Laplace transform can be used to describe the effect resulting from the dosing error: Please read the result on the next page.

The complete calculation of the disturbance analysis of the mixing quality can be found in the amixon® blog post: "Disturbance analysis of the mixing quality with Laplace transformation".